Preparation method of environment-friendly PVC core belt

A core belt, environmental protection technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of high cost, non-environmental protection, low efficiency, etc., and achieve good roller performance, environmental protection and low cost, The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Such as Figure 1-3 Shown, the preparation method of a kind of environment-friendly PVC core tape that an embodiment of the present invention proposes comprises the following preparation steps:

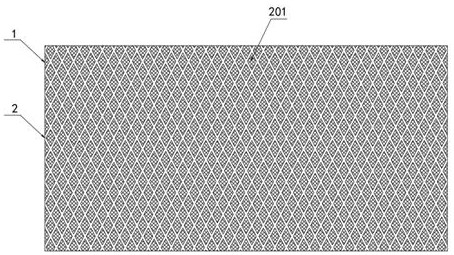

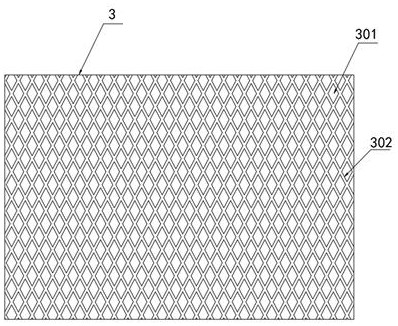

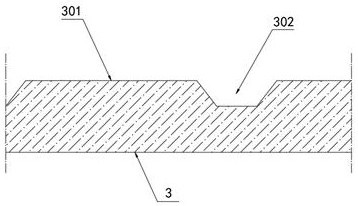

[0026] S1. Making the core belt: the multi-layer core belt woven with twisted aramid yarn and polyester filament is interwoven into a dense base layer 1, and warp-knitted spacer fabrics are made through polyester monofilaments to form the upper and lower layers of the dense base layer. A spacer fabric layer 2 with a mesh structure 201 to obtain an integral base core belt;

[0027] S2. Raw material preparation: raw materials including the following parts by weight: 45 parts of PVC resin, 15 parts of polyethylene resin, 9 parts of acetyl tributyl citrate, 7 parts of dioctyl adipate, 5 parts of polyisocyanate, 7 parts of talcum powder, 10 parts of light calcium carbonate, 1 part of antioxidant DSTP and 1 part of calcium stearate;

[0028] S3, preparation of extrusion coating: ad...

Embodiment 2

[0031] Such as Figure 1-3 Shown, the preparation method of a kind of environment-friendly PVC core tape that an embodiment of the present invention proposes comprises the following preparation steps:

[0032] S1. Making the core belt: the multi-layer core belt woven with twisted aramid yarn and polyester filament is interwoven into a dense base layer 1, and warp-knitted spacer fabrics are made through polyester monofilaments to form the upper and lower layers of the dense base layer. A spacer fabric layer 2 with a mesh structure 201 to obtain an integral base core belt;

[0033] S2. Raw material preparation: raw materials including the following parts by weight: 70 parts of PVC resin, 8 parts of polyethylene resin, 5 parts of acetyl tributyl citrate, 5 parts of dioctyl adipate, 3 parts of polyisocyanate, 3 parts of talcum powder, 5 parts of light calcium carbonate, 0.5 part of antioxidant DSTP and 0.5 part of calcium stearate;

[0034] S3, preparation of extrusion coating: ...

Embodiment 3

[0037] Such as Figure 1-3 Shown, the preparation method of a kind of environment-friendly PVC core tape that an embodiment of the present invention proposes comprises the following preparation steps:

[0038] S1. Making the core belt: the multi-layer core belt woven with twisted aramid yarn and polyester filament is interwoven into a dense base layer 1, and warp-knitted spacer fabrics are made through polyester monofilaments to form the upper and lower layers of the dense base layer. A spacer fabric layer 2 with a mesh structure 201 to obtain an integral base core belt;

[0039] S2, raw material preparation: comprise the raw material of following weight part: PVC resin 58 parts, polyethylene resin 12 parts, acetyl tributyl citrate 7 parts, dioctyl adipate 6 parts, polyisocyanate 4 parts, talcum powder 4 parts, 8 parts of light calcium carbonate, 0.5 part of antioxidant and 0.5 part of lubricant;

[0040] S3, preparation of extrusion coating: add the preparatory materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com