Tread pattern groove capable of reducing tire pumping noise

A tread pattern, tire pattern technology, applied in the direction of tire tread/tread pattern, tire parts, rolling resistance optimization, etc., can solve the problems of negligible tire noise performance, increased manufacturing cost, cumbersome manufacturing process, etc. Multiple properties, avoid force accumulation, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

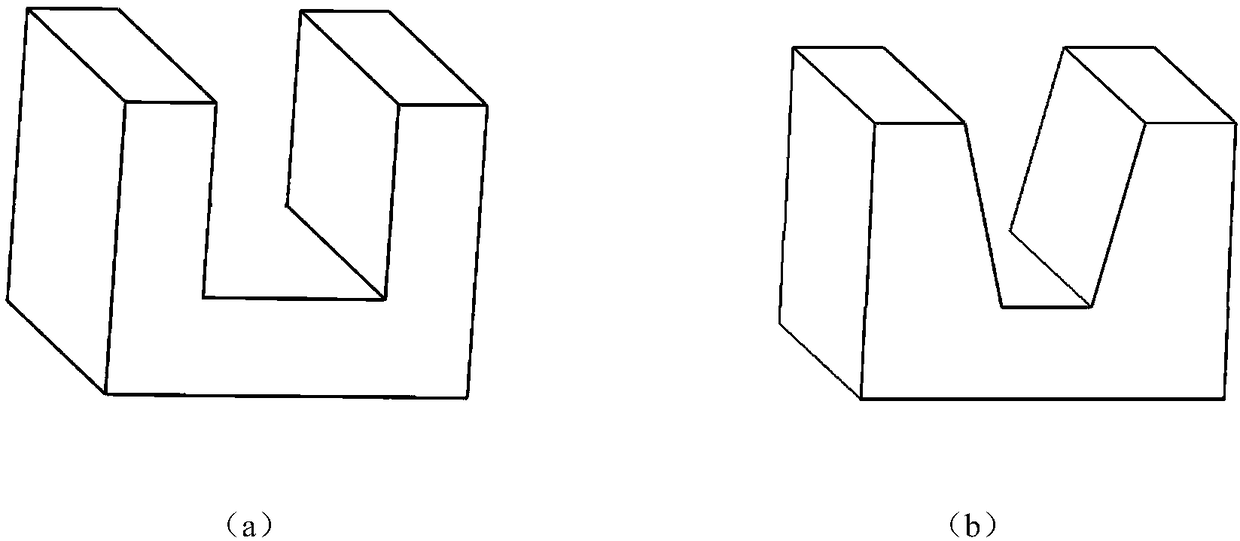

[0048] figure 2 A single arc-shaped raised pattern groove designed as a rectangular patterned groove perpendicular to the sidewall of the patterned groove; the peak of the arc-shaped raised pattern is located in the middle of the chord of the arc-shaped raised pattern.

[0049] It belongs to a kind of pattern groove of car tires. The original vertical plane longitudinal groove side wall is designed to have an arc-shaped convex pattern groove side wall. The radius of the arc-shaped convex arc contour line is between 2-15mm. The depth of this pattern groove is between 5-10mm. That is, the curvature of the arc contour line and the position of the convex peak can be adjusted according to the form of the pattern and the load. The curved design of the side wall of the pattern groove can increase the rigidity of the pattern groove, reduce the lateral deformation of the pattern and reduce the pumping noise of the pattern. The curvilinear design of the side wall of the pattern can p...

Embodiment 2

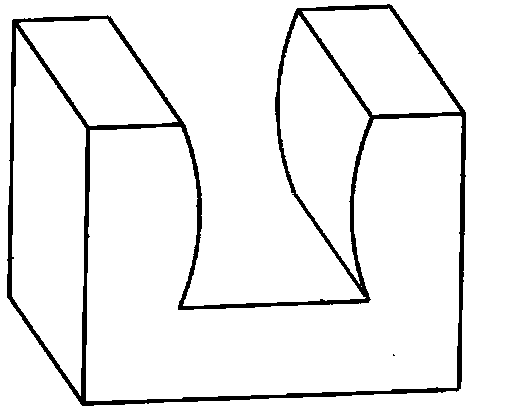

[0051] image 3 It is a plurality of arc-shaped convex pattern grooves designed for the vertical rectangular pattern grooves on the sidewall of the pattern groove. pattern. The radius of the arc contour line of each arc-shaped protrusion is between 2-15 mm. The curve arc radii corresponding to each convex peak of the multi-arc raised pattern groove is a proportional sequence, that is, R1: R2=R2: R3=R3: R4=...=X, the value of X Between 0.5-2. where R 1 , R 2 , R 3 , R 4 ,...,R N , R N-1 are the radii of the 1st, 2nd, 3rd, 4th, ..., N-1, and N arc-shaped convex arcs, respectively. The radius of the designed curved arc can gradually decrease from near the tread to the bottom of the groove, and can also gradually increase. The side wall of the pattern designed in such a curve can play a guiding role for the fluid in the groove, so that water or air can flow through the groove in an orderly manner, reducing the force of the fluid on the side wall of the pattern and the bo...

Embodiment 3

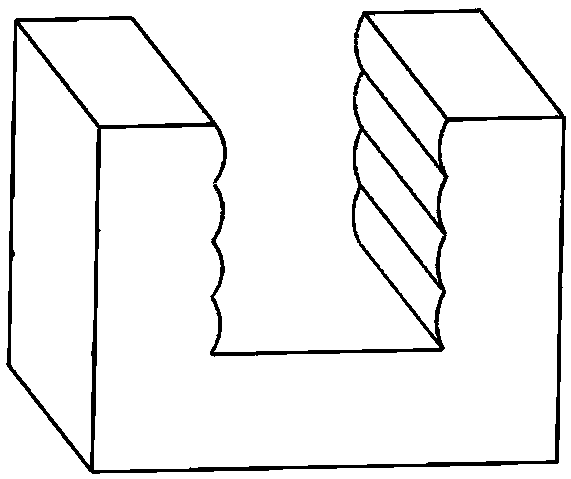

[0053] Figure 4 It is: a plurality of arc-shaped convex pattern grooves designed for vertical rectangular pattern grooves on the side walls of the pattern grooves, and the convex peaks of the arc-shaped projections are located below the middle of the chord of each arc-shaped projection s position.

[0054] For the pattern groove with multiple convex peaks at the lower position of the convex peaks, the curved arc corresponding to each convex peak on the side wall of the pattern is composed of two circular arcs. For the upper large arc and the lower small arc, the radius of curvature of the large arc is R’, and the radius of curvature of the small arc is r, where R 1 ’: R 2 ’ = R 2 ’: R 3 ’ = R 3 ’: R 4 ’=…=R N ’: R N-1 '=Y, the value of Y is between 0.5-2. where R 1 ’ between 2-15mm. r 1 :r 2 = r 2 :r 3 = r 3 :r 4 =…=r N :r N-1 =y, the value of y is between 0.5-2. This curve design is based on the physical model of water droplets falling in the air, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com