Process method for purifying aluminum substrate through solid-state phase change

A process method and solid-state phase transformation technology, applied in the field of aluminum alloy processing, can solve the problems of yield rate and product quality decline, high work hardening rate, cost increase, etc., and achieve industrial scale production, economical process system, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

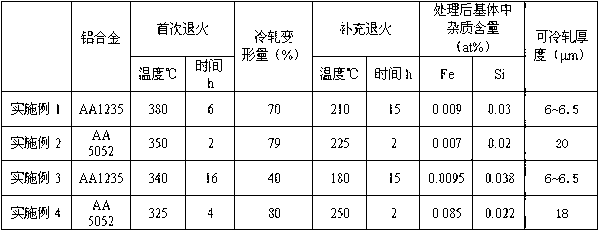

Embodiment 1

[0033] A process method for purifying the aluminum matrix through solid-state phase transformation. The 1.0mm thick hot-rolled plate (AA1235 alloy) is annealed at 380℃×6h, then cold-rolled to 0.3mm (the deformation is 70%), and then Supplementary annealing treatment at 210℃×15h.

[0034] The X-ray diffraction lattice constant method was used to quantitatively measure the concentration of Fe and Si elements in the matrix. The results showed that the contents of Fe and Si elements in the matrix were reduced to 0.009at% and 0.03at% respectively. The processed alloy has good rolling processability, greatly reduced work hardening rate, easy to reduce and reduce thickness, can be cold rolled to 6~6.5mm, and the yield is up to 85%.

Embodiment 2

[0036] A process method for purifying the aluminum matrix through solid-state phase transformation. The 2.6mm thick hot-rolled plate (AA5052 alloy) is annealed at 350℃×2h, then cold-rolled to 0.55mm (the deformation is 79%), and then Supplementary annealing treatment at 225℃×2h.

[0037] The X-ray diffraction lattice constant method was used to characterize the concentration of Fe and Si elements in the matrix. The results showed that the content of Fe and Si elements in the alloy matrix after the treatment was reduced to 0.007at% and 0.02at% respectively. The treated alloy has good rolling processing performance, greatly reduced work hardening rate, low rolling pressure, easy to deform, and can be cold rolled to below 20mm.

Embodiment 3

[0039] A process method for purifying the aluminum matrix through solid-state phase transformation. The 1.0mm thick hot-rolled plate (AA1235 alloy) is annealed at 340°C for 16h, then cold-rolled to 0.6mm (with a deformation of 40%), and then Supplementary annealing treatment at 180℃×15h.

[0040] The X-ray diffraction lattice constant method was used to quantitatively measure the concentration of Fe and Si elements in the matrix. The results showed that the contents of Fe and Si elements in the matrix were reduced to 0.0095at% and 0.038at% respectively. The processed alloy has good rolling processability, greatly reduced work hardening rate, easy to reduce and reduce thickness, can be cold rolled to 6~6.5mm, and the yield is up to 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com