Metal composite plate rolling method capable of strengthening deformation behavior of bonding interface

A metal composite plate, metal plate technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of low bonding strength of the metal composite plate interface, to reduce adverse effects, improve bonding strength, ensure The effect of shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

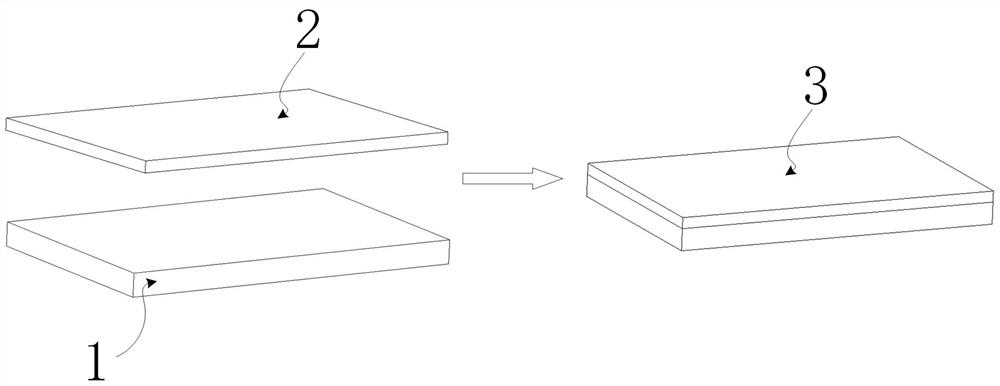

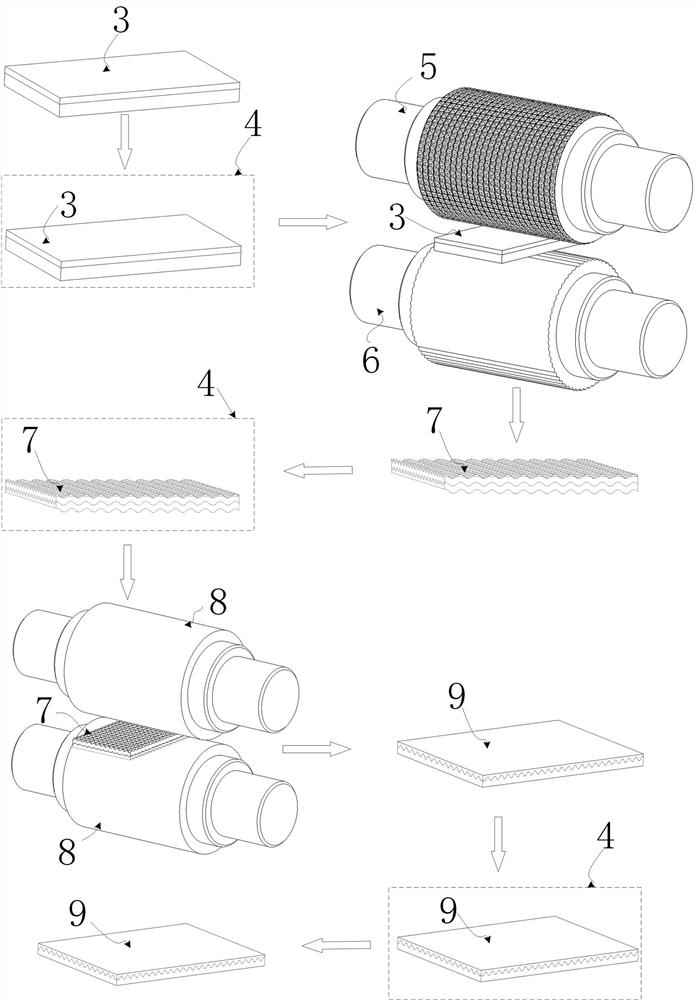

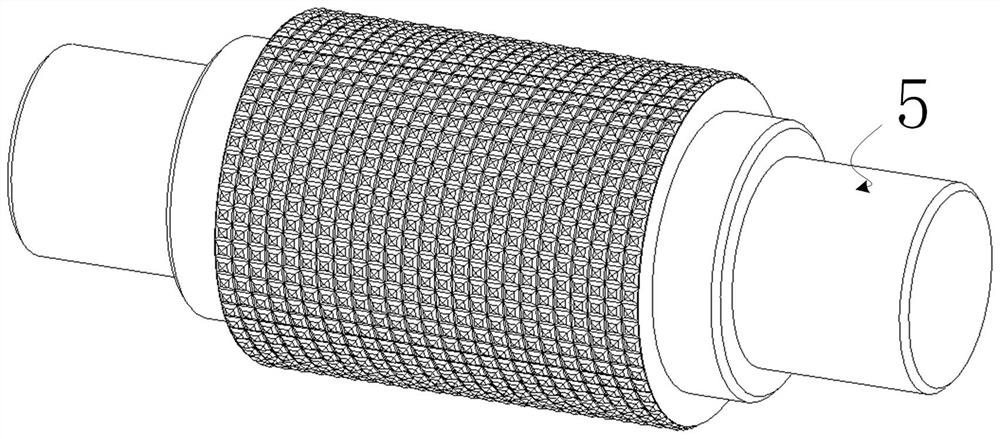

[0024] refer to Figure 1-7 , a Cu / Al clad plate rolling method capable of strengthening bonding interface deformation behavior, comprising the following steps:

[0025] S1. Blank making: Al plate with relatively small deformation resistance is selected as substrate 1, and the length, width and height are 50mm, 50mm, and 3mm respectively, and Cu with relatively large deformation resistance is selected as double plate 2, and the length, width, and height are 50mm and 50mm respectively , 1mm, the thickness ratio of the substrate 1 and the doubler board 2 is 3, use a wire brush to polish the surface of the substrate 1 and the doubler board 2 to be bonded, remove the surface oxide layer and pollutants, and stack the doubler boards 2 on the front of the substrate 1 Press the top and fix the edges (to ensure that the base plate 1 and double plate 2 will not be misaligned and deviated when they are subjected to non-uniform tangential force during the rolling process), and the metal c...

Embodiment 2

[0031] refer to Figure 1-7 , a Cu / Al clad plate rolling method capable of strengthening bonding interface deformation behavior, comprising the following steps:

[0032] S1. Blank making: Al plate with relatively small deformation resistance is selected as the substrate 1, and the length, width and height are 50, 50, and 3 mm respectively, and Cu with relatively large deformation resistance is selected as the doubler plate 2, and the length, width, and height are 50, 50 mm, respectively. , 1mm, the thickness ratio of the substrate 1 and the doubler board 2 is 3, use a wire brush to polish the surface of the substrate 1 and the doubler board 2 to be bonded, remove the surface oxide layer and pollutants, and stack the doubler boards 2 on the front of the substrate 1 Press the top and fix the edges (to ensure that the base plate 1 and double plate 2 will not be misaligned and deviated when they are subjected to non-uniform tangential force during the rolling process), and the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com