Recovery method for waste hard alloy and application

A technology of cemented carbide and recycling method, applied in the field of powder metallurgy, can solve the problems of ineffective and in-depth utilization, uneven quality of recycled alloys, reduced alloy recycling rate, etc., and achieves easy operation and energy loss. Small, high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

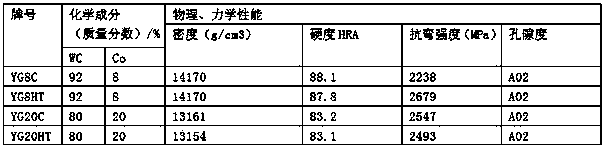

Examples

Embodiment 1

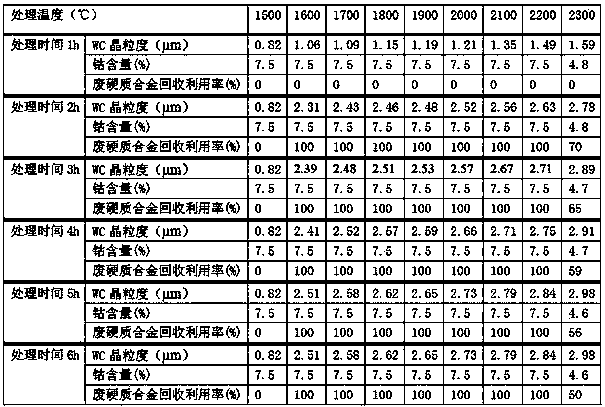

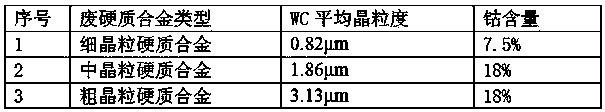

[0030] Mix the cemented carbides with serial numbers 1, 2, and 3 according to the mass ratio of 5:4:1 to obtain mixed waste cemented carbides, put them in an intermediate frequency furnace, and treat them at a high temperature of 1600°C for 4 hours. The average grain size of WC is 3.26μm, and the cobalt content is 12.75%.

Embodiment 2

[0032] Put the waste cemented carbide of No. 1 into an intermediate frequency furnace and treat it at a high temperature of 2200 ° C for 2 hours. After testing, the average WC grain size of the alloy is 2.63 μm, and the cobalt content is 7.5%.

Embodiment 3

[0034] Put the waste cemented carbide No. 2 into a carbonization furnace and treat it at a high temperature of 2200 ° C for 5 hours. After testing, the average WC grain size of the alloy is 3.05 μm, and the cobalt content is 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com