Manufacturing method of indium-tin oxide target material

A technology of indium tin oxide and its production method, which is applied in metal material coating process, ion implantation plating, coating, etc., and can solve the problems of high sputtering process, internal structure uniformity and grain size that cannot meet the requirements, etc. problem, to achieve the effect of excellent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

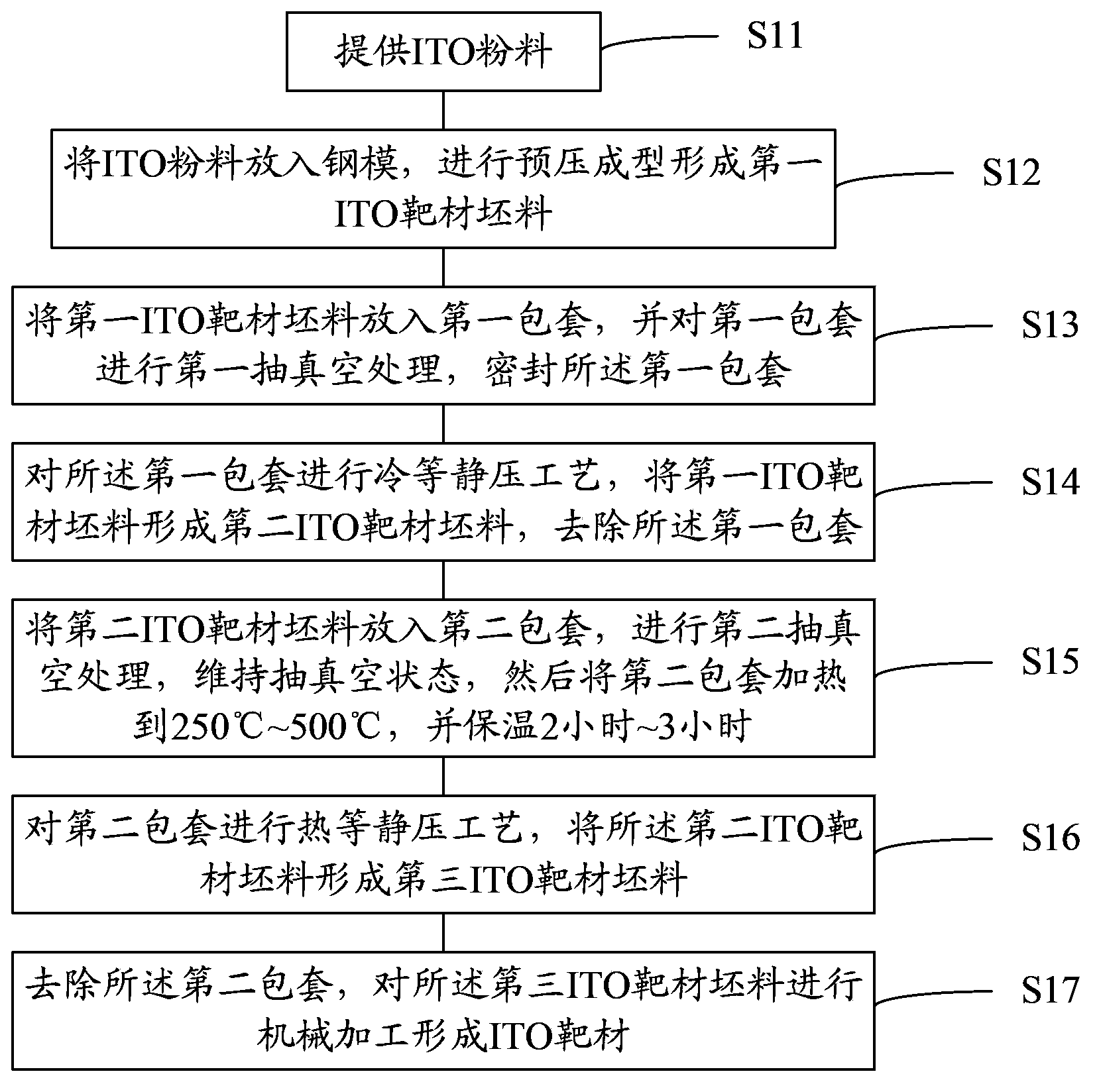

[0054] The inventors found that the powder for preparing the ITO target is mainly a mixture of indium oxide and tin oxide. reduction. Due to these characteristics, it is very difficult to prepare good quality ITO targets. However, the sintering method or the hot pressing method used in the existing technology to prepare the ITO target cannot fully solve the problems caused by the characteristics of the ITO powder.

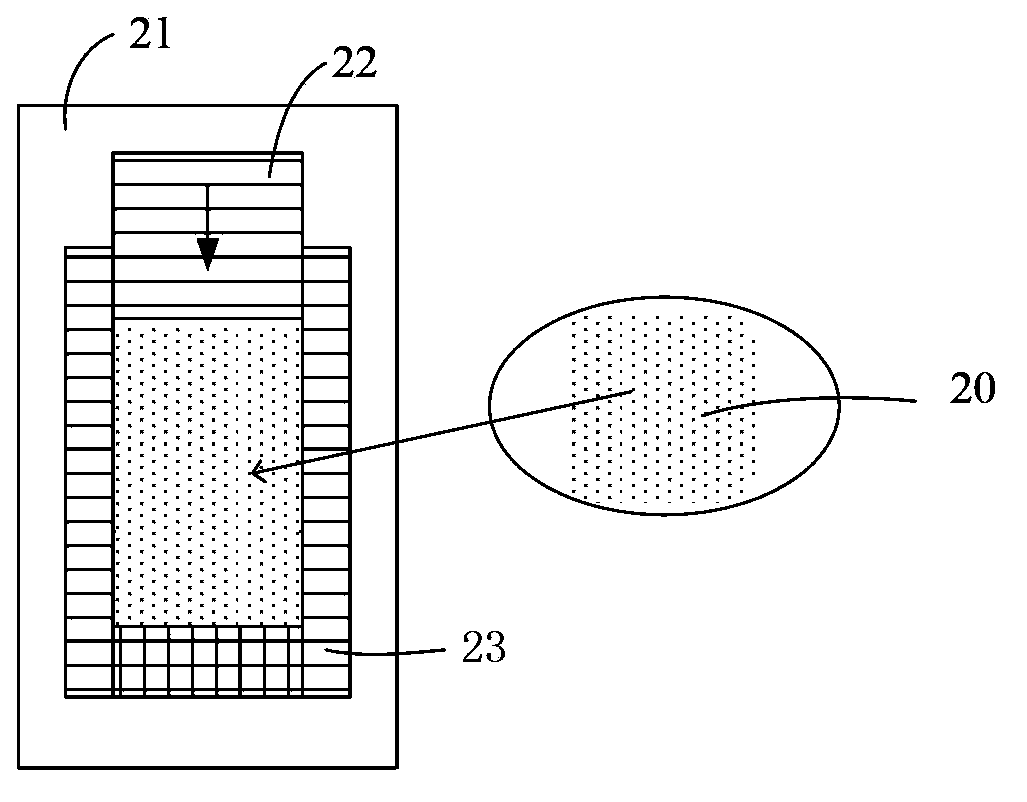

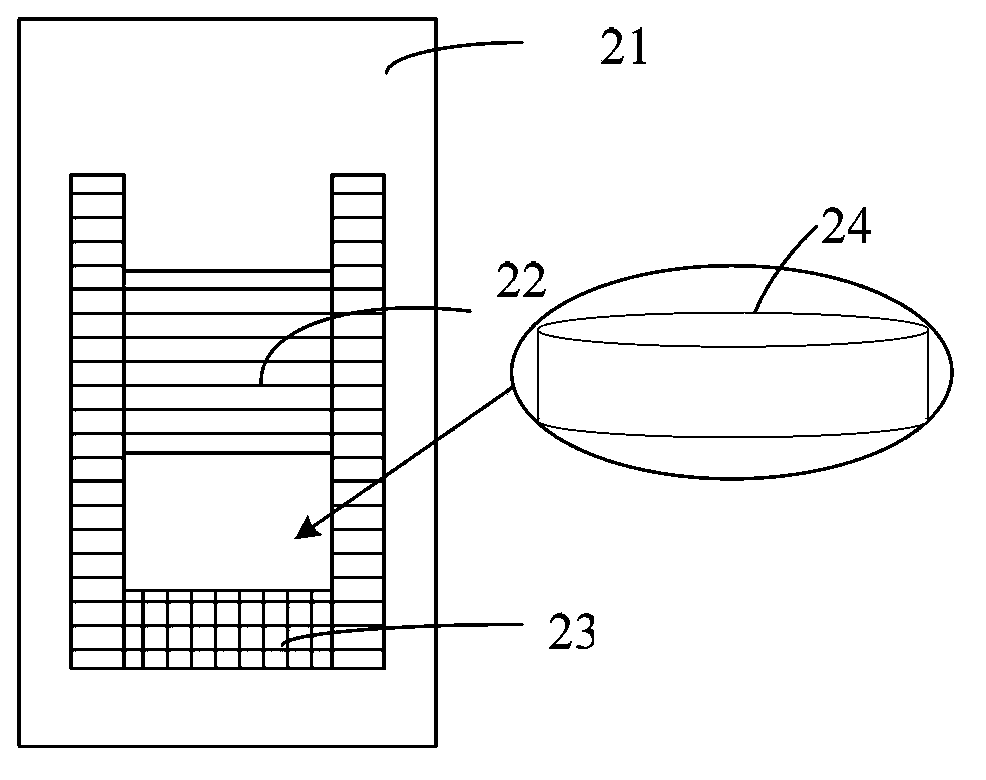

[0055] In view of this, the inventor proposes to prepare the ITO target mainly by combining cold isostatic pressing and hot isostatic pressing. Since cold isostatic pressing and hot isostatic pressing can provide isotropic uniform pressure, the degree of densification of the target blank is consistent, thereby achieving an ITO target with a uniform internal structure.

[0056] The hot isostatic pressing has the advantages of both isotropic pressure and hot pressing, and can further densify the ITO target blank on the basis of the previous cold isostatic pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com