Method for manufacturing non-oriented high-silicon steel cold-rolled sheet based on strip casting and did

A cold-rolled thin plate and thin-strip casting-rolling technology, applied in the field of metallurgy, can solve the problems of low cold processing performance of non-oriented high-silicon steel, deterioration of the magnetic properties of the final product, and unsatisfactory magnetic induction values, and achieve low equipment requirements and room temperature toughness Improve and optimize the effect of magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Smelting liquid steel, its composition is C 0.005%, Si 6.5%, N 0.003%, O 0.002%, S 0.004% by weight percentage, and the balance is Fe;

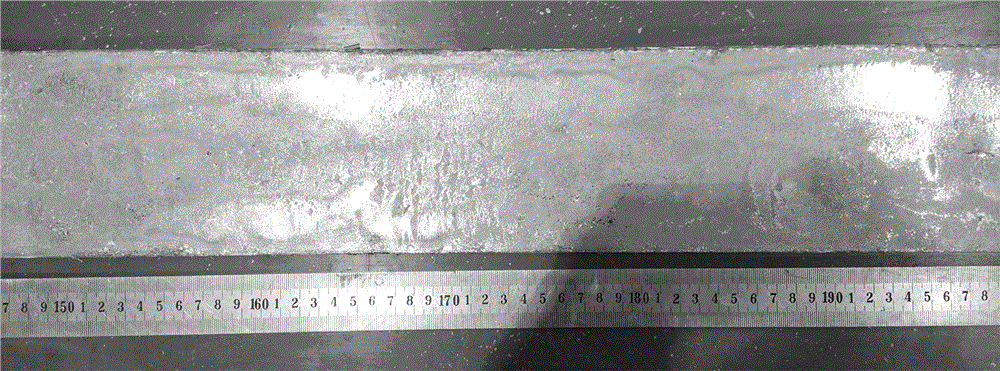

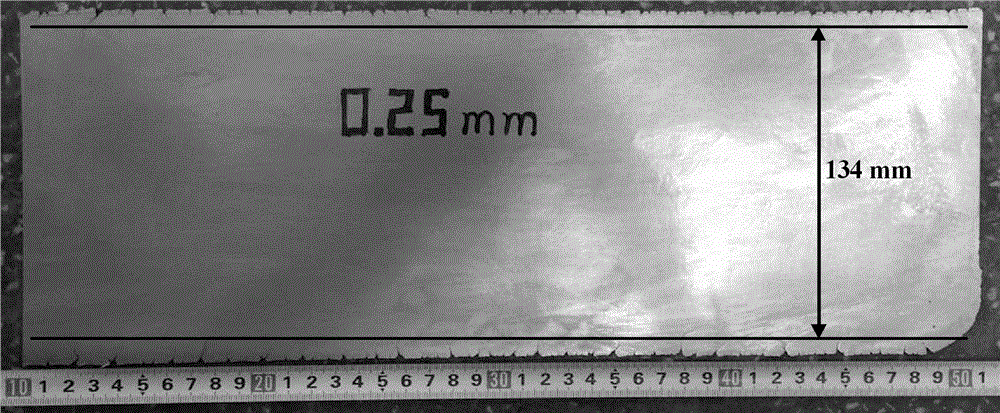

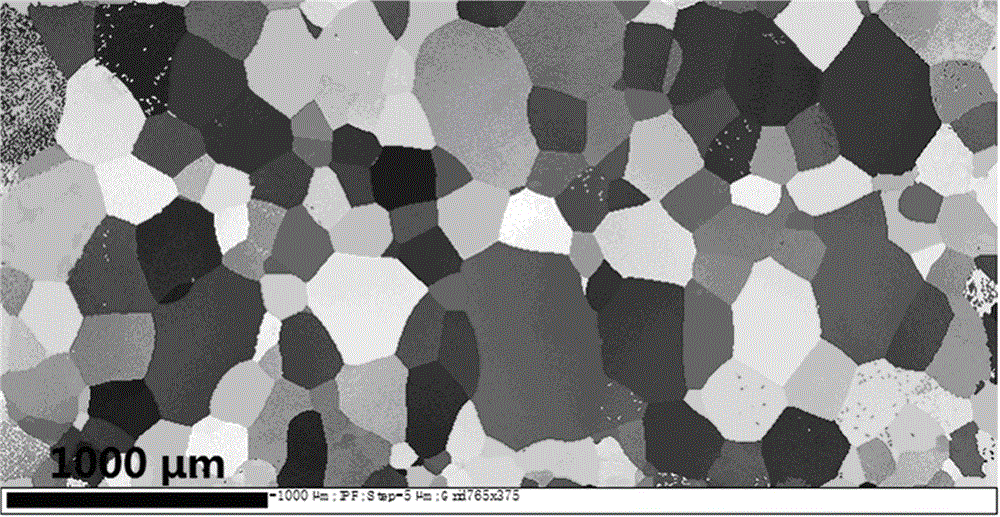

[0030] The molten steel in the molten state is cast and rolled by thin strip casting and rolling equipment, and air-cooled to room temperature to obtain a cast strip with a thickness of 2.5 mm and an equiaxed grain structure with an average grain size of 240 μm; the pouring temperature during casting and rolling is 1565°C; the superheat of molten steel on the upper surface of the molten pool is 10°C during pouring; the appearance of the cast strip is as follows figure 1 As shown, the internal organization is as figure 2 shown;

[0031] The cast strip is hot-rolled into a hot-rolled plate, the rolling speed is 3m / s, the starting temperature of each pass is 1050±10°C, and the total hot-rolling reduction rate is 52%;

[0032] The hot-rolled sheet is warm-rolled into a warm-rolled sheet, and the strain-induced disorder effect occurs dur...

Embodiment 2

[0036] Smelting molten steel, its composition by weight percentage is C 0.004%, Si 6.4%, N 0.003%, O 0.003%, S 0.003%, and the balance is Fe;

[0037]The molten steel in the molten state is cast and rolled by thin strip casting and rolling equipment, and air-cooled to room temperature to obtain a cast strip with a thickness of 3 mm and an equiaxed grain structure with an average grain size of 270 μm; the pouring temperature during casting and rolling is 1570 ℃; the superheat of molten steel on the upper surface of the molten pool is 15℃ during pouring;

[0038] The cast strip is hot-rolled into a hot-rolled plate, the rolling speed is 3m / s, the starting temperature of each pass is 1050±10°C, and the total hot-rolling reduction rate is 57%;

[0039] The hot-rolled sheet is warm-rolled into a warm-rolled sheet, and the strain-induced disorder effect occurs during the warm-rolling process. The starting temperature of each pass is 100±5°C, the final rolling temperature is 80±5°C, ...

Embodiment 3

[0043] Smelting molten steel, its composition is C 0.003%, Si 6.6%, N 0.002%, O 0.003%, S 0.004% by weight percentage, and the balance is Fe;

[0044] The molten steel in the molten state is cast and rolled by thin strip casting and rolling equipment, and air-cooled to room temperature to obtain a cast strip with a thickness of 2.6 mm, an equiaxed grain structure, and an average grain size of 200 μm; the pouring temperature during casting and rolling is 1575°C; the superheat of molten steel on the upper surface of the molten pool is 20°C during pouring;

[0045] The cast strip is hot-rolled into a hot-rolled plate, the rolling speed is 3m / s, the starting temperature of each pass is 1050±10°C, and the total hot-rolling reduction rate is 62%;

[0046] The hot-rolled sheet is warm-rolled into a warm-rolled sheet, and the strain-induced disorder effect occurs during the warm-rolling process. The starting temperature of each pass is 100±5°C, the final rolling temperature is 80±5°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com