High-strength high-plasticity Mg-Gd-Y-Ni-Mn alloy and preparing method thereof

A mg-gd-y-ni-mn, high-strength technology, applied in the field of wrought magnesium alloy and its manufacturing, can solve the problems of difficult control of metal Zr smelting, elongation of only 1.1%, and increased difficulty in alloy preparation. Easy operation, simple formula, low extrusion ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

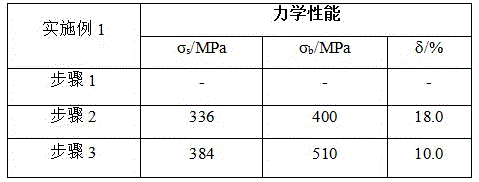

Embodiment 1

[0029] Example 1: A high-strength and high-plasticity Mg-Gd-Y-Ni-Mn alloy, alloy composition (weight percentage): Gd-8.14%, Y-3.83%, Ni-1.51%, Mn-0.76%, less than 0.1% of impurity elements , and the rest are Mg.

[0030] The manufacture method of this high-strength and high-plasticity Mg-Gd-Y-Ni-Mn alloy is carried out as follows:

[0031] Step 1: In a vacuum melting furnace, the ingot is melted, and argon is introduced for protection, and alloying elements are added according to the weight percentage of Gd-8.14%, Y-3.83%, Ni-1.51%, and Mn-0.76%. Among them, Gd, Y, Ni, and Mn were added in the form of Mg–30wt%Gd, Mg–25wt%Y, Mg–4wt%Mn, and Ni–30wt%Y master alloys, respectively.

[0032] Insulate at 850°C and stir with electromagnetic induction to fully melt the raw materials. After the alloy is completely melted, continue to stand at 850°C for 10 minutes, and then cast.

[0033] Step 2: Homogenize the smelted magnesium alloy ingot. The process parameters are as follows: put...

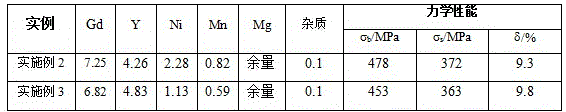

Embodiment 2

[0038] Example 2: A high-strength Mg-Gd-Y-Ni-Mn alloy, alloy composition (weight percent): Gd-7.25%, Y-4.26%, Ni-2.28%, Mn-0.82%, less than 0.1% of impurity elements, the rest for magnesium.

[0039] The manufacturing method of this high-strength Mg-Gd-Y-Ni-Mn alloy is the same as that of Example 1.

Embodiment 3

[0040] Example 3: A high-strength Mg-Gd-Y-Ni-Mn alloy, alloy composition (weight percent): Gd-6.82%, Y-4.83%, Ni-1.13%, Mn-0.59%, less than 0.1% of impurity elements, and the rest for magnesium.

[0041] The manufacturing method of this high-strength Mg-Gd-Y-Ni-Mn alloy is the same as that of Example 1.

[0042] Table 2 is a table of mechanical properties of the high-strength Mg-Gd-Y-Ni-Mn alloy described in Examples 2-5.

[0043]

[0044] The invention proposes that Mg, Gd, Y and Ni form a large number of long-period phases in the Mg-Y-Ni-Mn alloy, which can play a significant effect of dispersion strengthening. Then through extrusion deformation and multi-stage heat treatment to enhance the strengthening effect, add an appropriate amount of Mn element, through process control, make Mn dispersed in the form of single particles to further refine the grain and improve the mechanical properties. This process is solid solution strengthening and deformation strengthening. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com