A Method for Optimizing the Shape of Non-Oriented High Silicon Steel Cold Rolled Sheet

A high-silicon steel and cold-rolled sheet technology is applied in the field of optimizing the shape of non-oriented high-silicon cold-rolled steel sheets to prevent internal stress, improve room temperature toughness, and optimize the shape of the sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Melt steel is smelted, and then thin strip casting and rolling machine is used to prepare silicon steel casting strip, the thickness is 2.5mm, and the chemical composition contains C 0.0083%, Si 6.55%, N 0.0022%, O 0.0027%, S 0.0076% by weight percentage, and the balance is Fe; The silicon steel cast strip is hot-rolled to obtain a hot-rolled steel plate; the hot-rolling temperature is 900°C, and the total reduction is 40%;

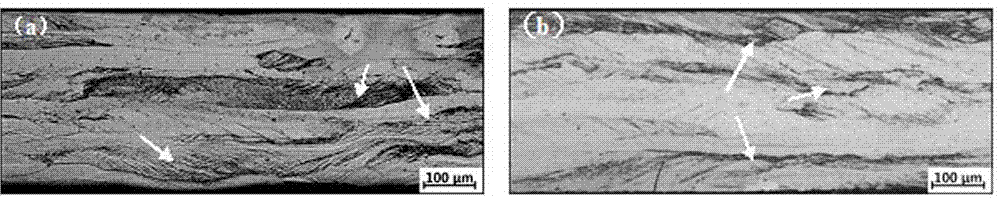

[0029] The hot-rolled steel plate is warm-rolled at 100°C, and the total reduction of warm rolling is 60%, to obtain a warm-rolled steel plate; the metallographic structure is as follows: figure 1 as shown in (a);

[0030] The warm-rolled steel plate was kept at 350°C and a protective atmosphere for 30 minutes for low-temperature recovery, then air-cooled to room temperature, and the protective atmosphere was nitrogen; the metallographic structure is as follows: figure 1 as shown in (b);

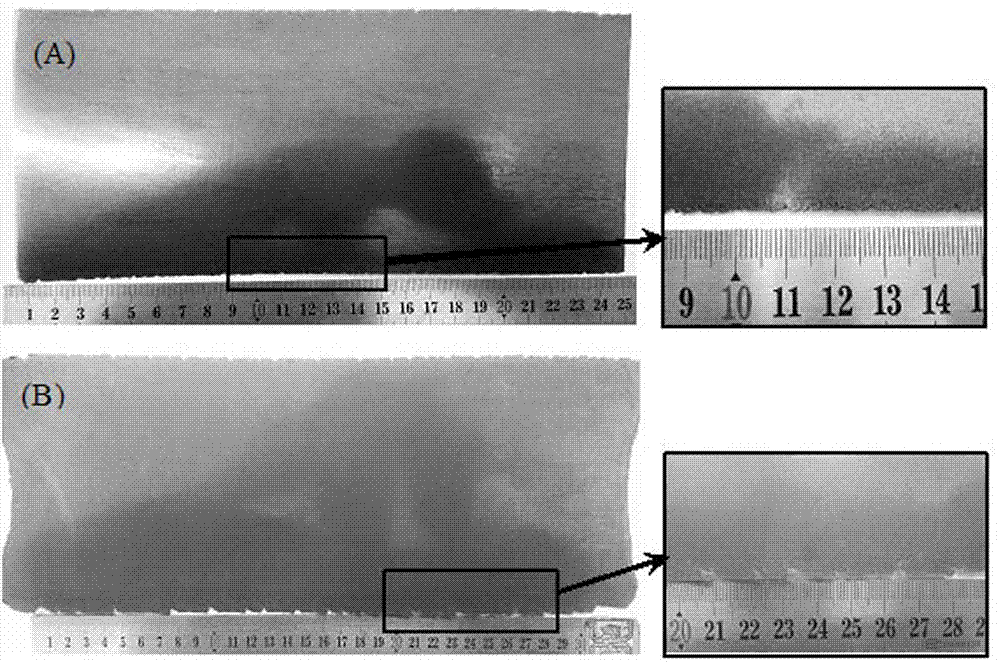

[0031] Carry out cold rolling again, the total reduction ...

Embodiment 2

[0034] Method is with embodiment 1, and difference is:

[0035] (1) The thickness of the silicon steel cast strip is 2.4mm, and the composition contains C 0.008, Si 6.50%, N 0.0025%, O0.0024%, S 0.0075% by weight percentage; the hot rolling temperature is 1000°C, and the total reduction is 60% ;

[0036] (2) Warm rolling is carried out at 150°C, and the total reduction of warm rolling is 55%;

[0037] (3) Keep warm for 40 minutes at 340°C and protective atmosphere;

[0038] (4) The total reduction of cold rolling is 40%;

[0039] Non-oriented high-silicon steel cold-rolled sheets have slight edge cracks and good shape.

Embodiment 3

[0041] Method is with embodiment 1, and difference is:

[0042] (1) The thickness of the silicon steel cast strip is 2.3mm, and the composition contains 0.009% of C, 6.45% of Si, 0.0026% of N, 0.0028% of O, and 0.0071% of S by weight percentage; the hot rolling temperature is 1050°C, and the total reduction is 56% ;

[0043] (2) Warm rolling is carried out at 200°C, and the total reduction of warm rolling is 58%;

[0044] (3) Keep warm for 50 minutes at 320°C and protective atmosphere;

[0045] (4) The total reduction of cold rolling is 30%;

[0046] Non-oriented high-silicon steel cold-rolled sheets have slight edge cracks and good shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com