A kind of preparation method of environment-friendly cold-resistant polyvinyl chloride elastomer composition

A polyvinyl chloride and elastomer technology, applied in the field of materials, can solve the problems of high raw material cost of diethylene glycol dibenzoate plasticizer, the influence of elastomer normal temperature toughness and low temperature toughness, and unsatisfactory low temperature resistance, etc. , achieve excellent plasticizing effect, good heat aging resistance, and improve room temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of the above-mentioned environment-friendly and cold-resistant polyvinyl chloride elastomer composition, comprising the following steps:

[0030] Step 1: Stir and mix each component in a kneader evenly, and use the friction heat generated by stirring to raise the temperature of the mixture;

[0031] Step 2: After the temperature of the mixture of the components in the kneader rises to 90-100°C, the material is discharged, and then sent to the cooling agitator to cool to below 45°C;

[0032] Step 3: Put the cooled mixture on a two-stage screw extruder to extrude the material. The two-stage screw extruder includes a twin-screw extruder and a single-screw extruder. The twin-screw extruder four The temperatures of each heating zone and the extrusion die are respectively: T1=85~100°C, T2=100~120°C, T3=120~140°C, T4=130~150°C, T die=130~150°C; The temperatures of the heating zone and the extrusion die of the single-scr...

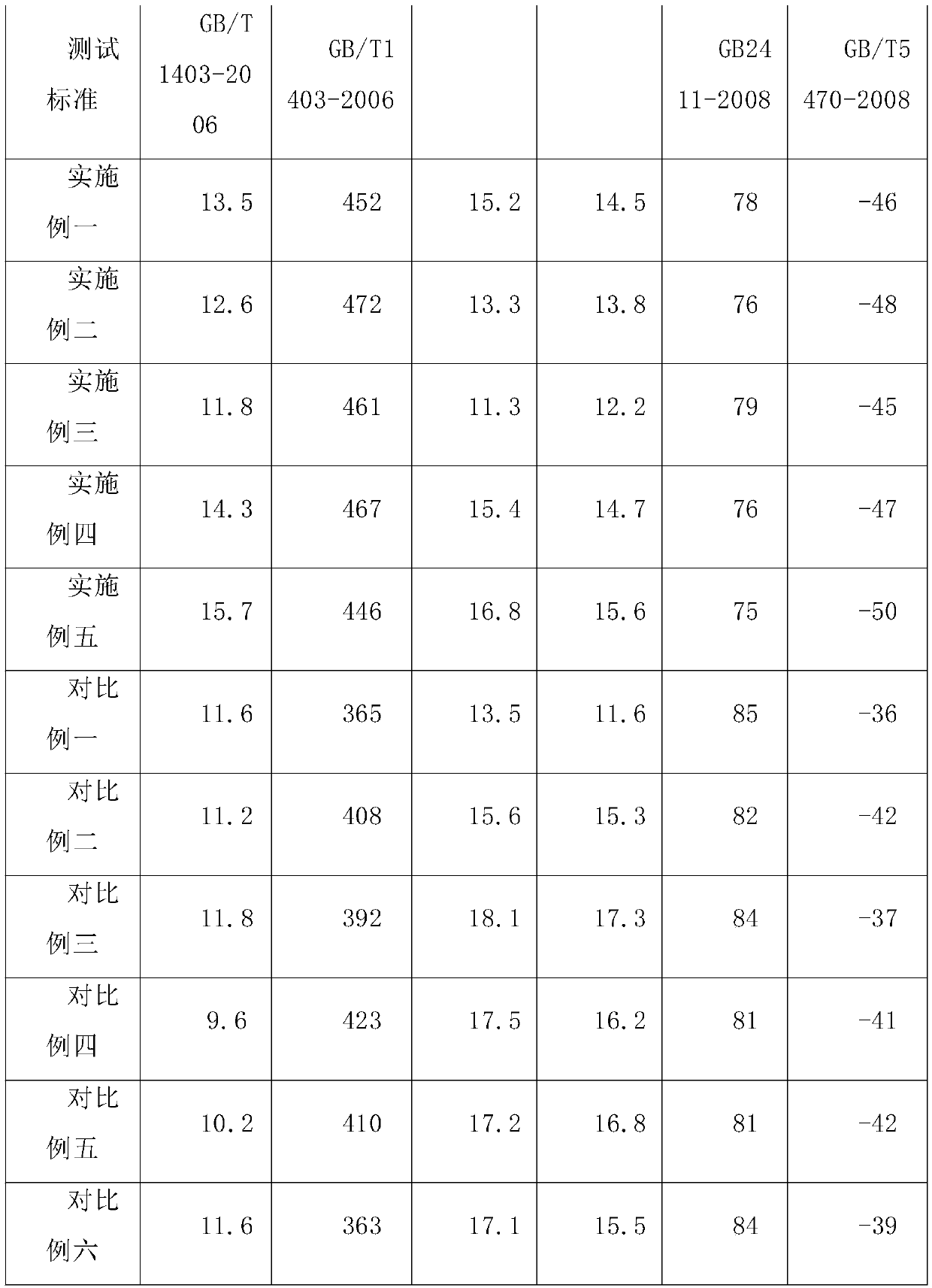

Embodiment 1

[0034]With the polyvinyl chloride resin of 100 weight parts, the dioctyl terephthalate of 75 weight parts, the epoxy soybean oil of 25 weight parts, the polyurethane rubber of 10 weight parts, the nano active calcium carbonate of 15 weight parts, 5 weight parts Calcium-zinc composite stabilizer, 1.5 parts by weight of zinc stearate, 0.6 parts by weight of four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 1 part by weight of The high-pigment carbon black is stirred and mixed at high speed in the kneader. The frictional heat generated by the stirring makes the temperature of the mixed material rise to 90-100°C, and then the material is discharged. The material is extruded and granulated on a twin-screw extruder, wherein the temperatures of the four heating zones of the twin-screw extruder and the extrusion die are respectively: T 1 =85~100℃, T 2 =100~120℃, T 3 =120~140℃, T 4 =130~150℃, T 模 =130-150°C; the temperatures of the heating zone and e...

Embodiment 2

[0036] With the polyvinyl chloride resin of 100 weight parts, the diheptyl terephthalate of 90 weight parts, the epoxy group esterified linseed oil of 10 weight parts, the ethylene-vinyl acetate copolymer of 20 weight parts (vinyl acetate weight percent 40%), 5 parts by weight of nano-active calcium carbonate, 8 parts by weight of calcium-zinc composite stabilizer, 1 part by weight of polyethylene wax, 0.2 parts by weight of tetrakis [β-(3,5-di-tert-butyl- 4-hydroxyphenyl) propionic acid] pentaerythritol ester and 3 parts by weight of rutile titanium dioxide are stirred and mixed at high speed in a kneader. The cooling mixer is cooled to below 45°C, and then the cooled mixture is extruded on a twin-screw extruder for granulation, where the temperatures of the four heating zones of the twin-screw extruder and the extrusion die are: T 1 =85~100℃, T 2 =100~120℃, T 3 =120~140℃, T4 =130~150℃, T 模 =130-150°C; the temperatures of the heating zone and extrusion die of the single-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com