High-strength cat magnesium alloy and preparation method thereof

A technology for casting magnesium alloys and magnesium alloys, which is applied in the field of high-strength and toughness casting magnesium alloys and their preparation, can solve problems such as low strength and toughness, and achieve the effects of low alloy cost, mature melting process and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

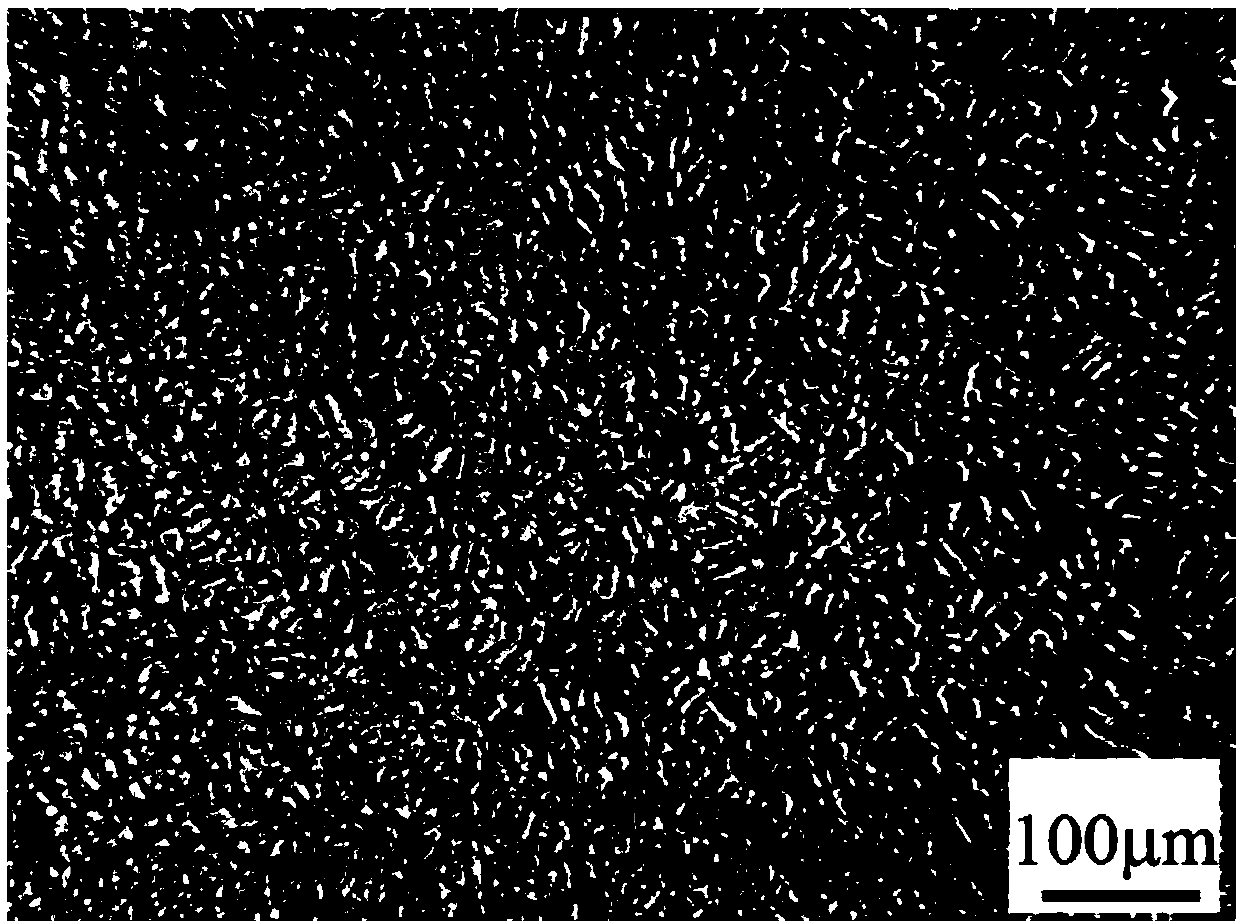

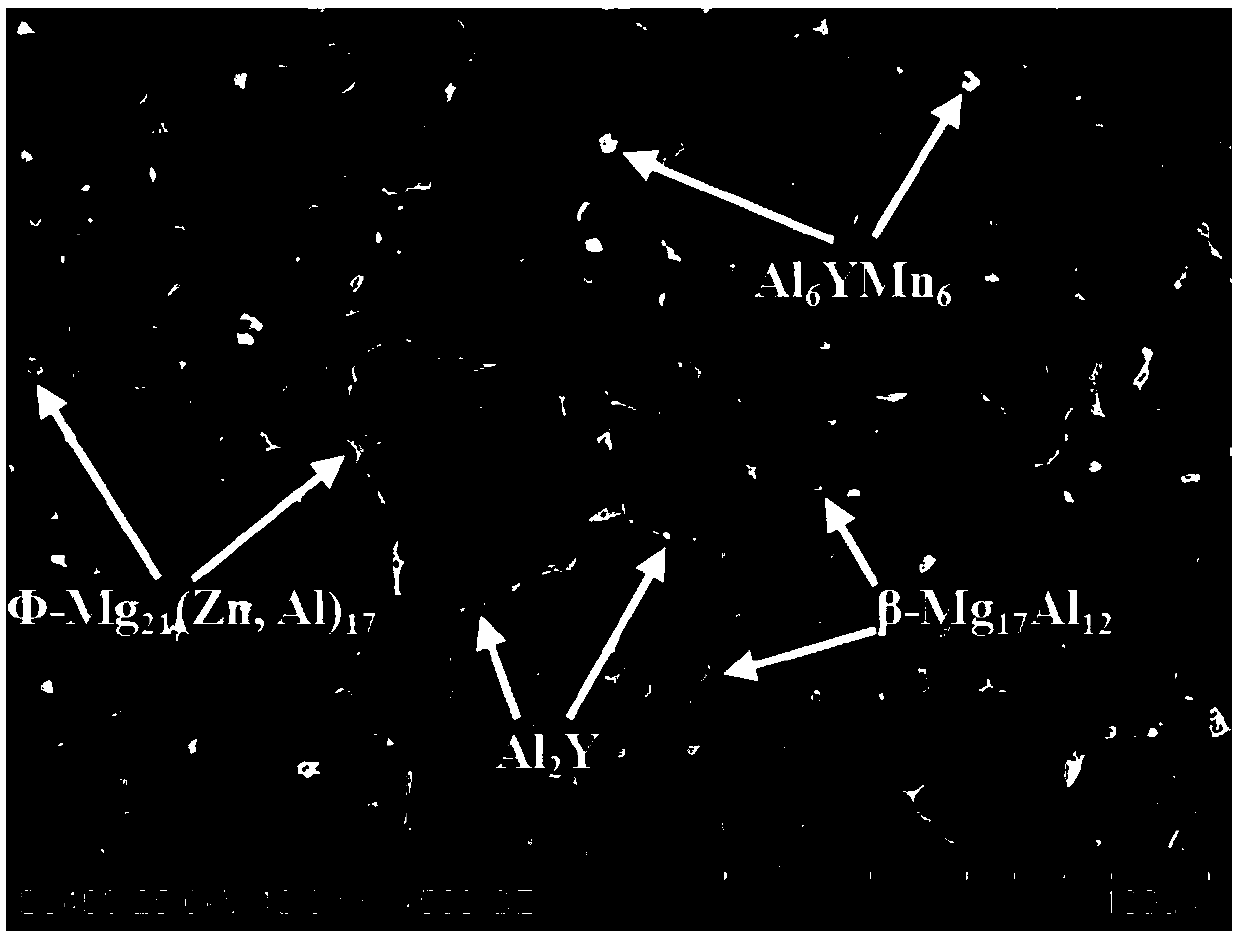

preparation example Construction

[0025] A method for preparing a high-strength and toughness casting magnesium alloy, the method steps are as follows: select an industrial magnesium alloy AM50 ingot as a master alloy, preheat the master alloy ingot to 200-250°C, and 6 and N 2 Melt in a melting furnace protected by a mixed gas. After the master alloy is completely melted, raise the temperature to 700°C. Preheat the Mg-25%Y master alloy and directly add it to the melt. After it is completely melted, preheat Add pure Zn into the alloy melt, stir and mix evenly, let it stand for 20-30 minutes, then remove the surface scum, and pour it into a metal mold with a preheating temperature of 200°C.

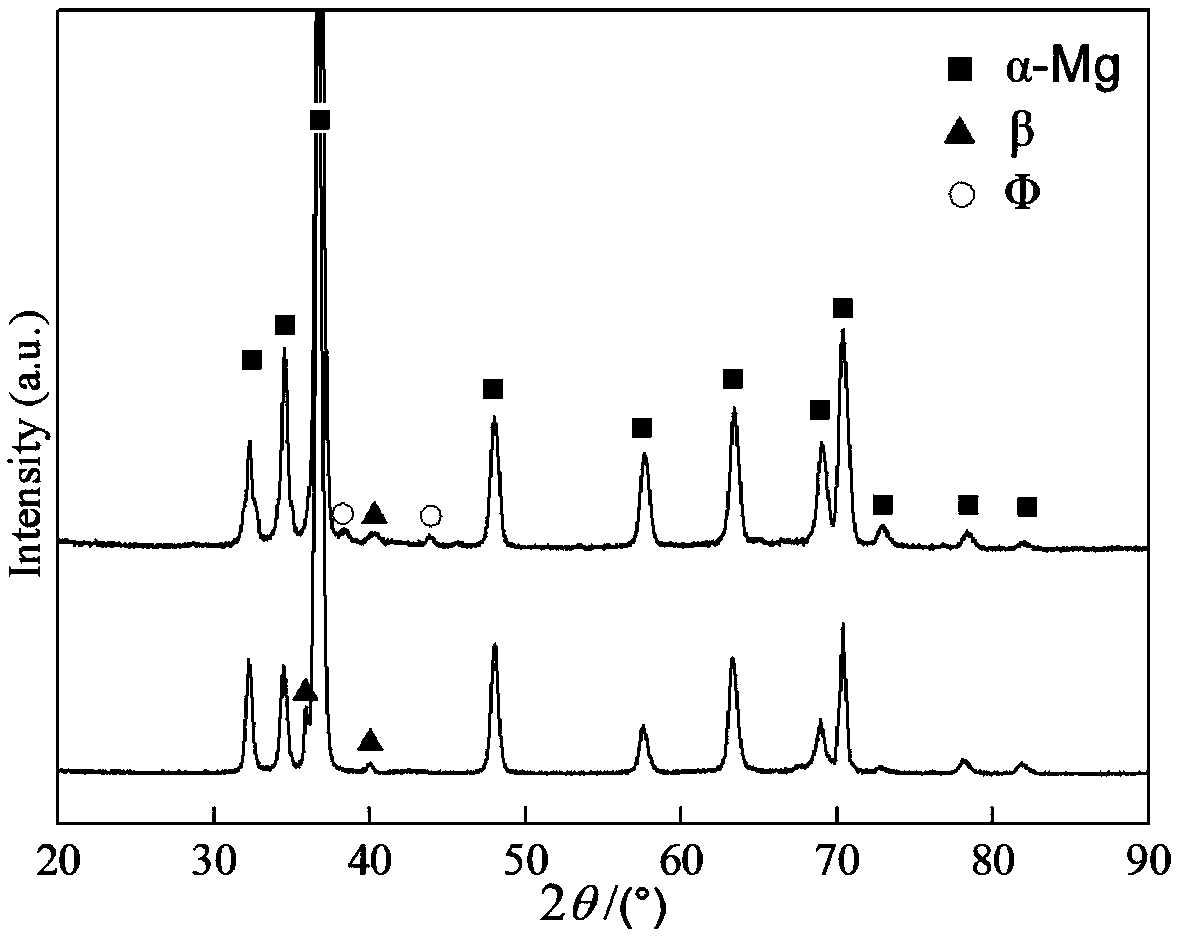

[0026] The tensile strength of the alloy at room temperature is 205-215MPa, the yield strength is 100-110MPa, and the elongation is 9.5%-11%.

[0027] Such as Figure 4 Shown, the tensile mechanical property of AM50-Zn-Y alloy of the present invention is obviously better than AM50 alloy.

Embodiment 1

[0029] Select the industrial magnesium alloy AM50 as the master alloy, preheat the alloy to 200°C, and 6 and N 2 Melting under the protection of a mixed gas, the temperature is raised to 700 ° C, the Mg-25%Y master alloy is preheated and directly added to the melt, and after it is completely melted, the preheated pure Zn is added to the alloy melt. Stir to mix evenly, let it stand for 20 minutes, then remove the scum on the surface and pour it.

[0030] The composition of the casting obtained is shown in the following table (mass percentage):

[0031]

[0032] The tensile strength at room temperature is 205.8MPa, the yield strength is 100.2MPa, and the elongation is 11.0%.

Embodiment 2

[0034] Select the industrial magnesium alloy AM50 as the master alloy, preheat the alloy to 220°C, and 6 and N 2 Melting under the protection of a mixed gas, the temperature is raised to 700 ° C, the Mg-25%Y master alloy is preheated and directly added to the melt, and after it is completely melted, the preheated pure Zn is added to the alloy melt. Stir to mix evenly, let it stand for 30 minutes, scrape off the surface scum, and pour it.

[0035] Obtain the composition of casting as follows (mass percentage):

[0036]

[0037] The tensile strength at room temperature is 206.6MPa, the yield strength is 105.2MPa, and the elongation is 10.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com