High-density tungsten alloy containing rare earth oxide for armor-piercing bullet core and preparation method thereof

A high-density tungsten alloy and rare earth oxide technology, which is applied in the direction of ammunition, warheads, projectiles, etc., can solve the problems of unstable performance and low comprehensive mechanical properties, and achieve stable performance control, high plasticity, and excellent comprehensive mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

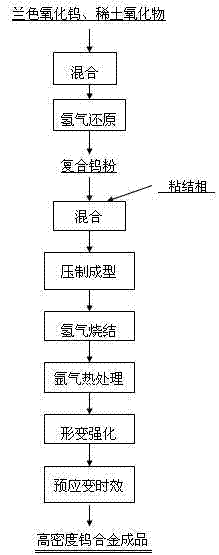

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the high-density tungsten alloy containing rare earth oxides for the armor-piercing projectile core of the present invention includes the following steps (taking the preparation of 100 kg of high-density tungsten alloy as an example, the same below):

[0028] Step 1: Preparation of composite tungsten powder containing rare earth oxides

[0029] Mix 115.2 kg of blue tungsten oxide (folded metal W: 92.0 kg) and 1 kg of rare earth oxide lanthanum oxide in a mixer for 12 hours, and then mix the mixed oxide in three stages at temperatures of 750°C, 850°C, and 960°C. The reduction is carried out in the 15-tube hydrogen reduction furnace in the temperature zone, and the hydrogen flow rate is: 3m 3 / h, the speed of pushing the boat is 8mm / min; the reduced composite tungsten powder containing tungsten powder and rare earth oxide is sieved through a 120-mesh sieve.

[0030] Step 2: Preparation of the mixture

[0031] Mix 93 kg of composite tun...

Embodiment 2

[0045] Step 1: Preparation of composite tungsten powder containing rare earth oxides

[0046] Mix 118.9 kg of blue tungsten oxide (folded metal W: 95.0 kg) and 0.05 kg of cerium oxide in a mixer for 18 hours, and then mix the mixed oxide in three temperature zones with temperatures of 700°C, 820°C, and 900°C for ten The reduction is carried out in a five-tube hydrogen reduction furnace, and the hydrogen flow rate is: 2m 3 / h, the speed of pushing the boat is 5 mm / min; the reduced composite tungsten powder containing tungsten powder and rare earth oxide is sieved through a 200-mesh sieve.

[0047] Step 2: Preparation of the mixture

[0048] Mix 95.05 kg of composite tungsten powder, 3.95 kg of nickel powder and 1.0 kg of iron powder in a mixer for 12 hours, then pass the mixture through a 140-mesh screen.

[0049] Step 3: Compression molding

[0050] Put the mixed powder into a rubber sleeve and press to form in an isostatic press with a pressing pressure of 200 MPa ...

Embodiment 3

[0063] A method for preparing a high-density tungsten alloy containing rare earth oxides for an armor-piercing projectile core comprises the following steps:

[0064] Step 1: Preparation of composite tungsten powder containing rare earth oxides

[0065] Mix 113.3 kg of blue tungsten oxide (folded metal W: 90.5 kg) with 1 kg of cerium oxide and 1 kg of lanthanum oxide in a mixer for 14 hours, and then mix the mixed oxides at temperatures of 730°C, 880°C, and 980°C, respectively. Reduction is carried out in a fifteen-tube hydrogen reduction furnace with three temperature zones, and the hydrogen flow rate is: 5m 3 / h, the speed of pushing the boat is 10mm / min; the reduced composite tungsten powder containing tungsten powder and rare earth oxide is sieved through a 200-mesh sieve.

[0066] Step 2: Preparation of the mixture

[0067] Mix 92.5 kg of composite tungsten powder with 4.9 kg of nickel powder, 2.1 kg of iron powder, 0.44 kg of cobalt powder, and 0.06 kg of manga...

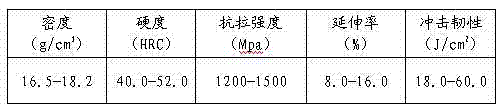

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com