Loom for conical and cylindrical shell three-dimensional fabric

A three-dimensional fabric and cylinder technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of weak overall mechanical properties of fabrics, poor accuracy of fabric profile dimensions, uneven yarn density, etc. The effect of uneven density, simple structure and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

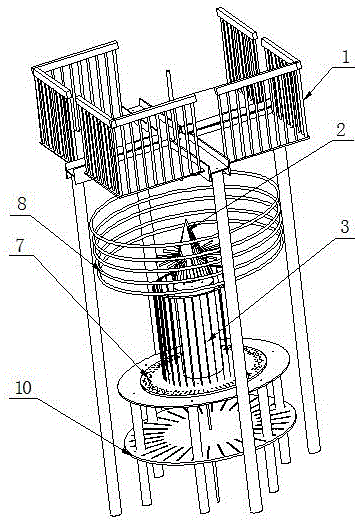

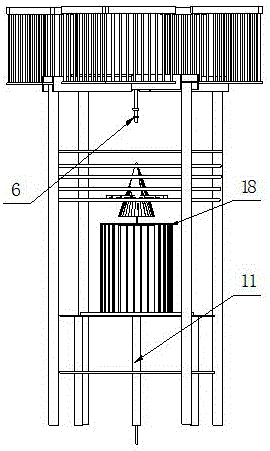

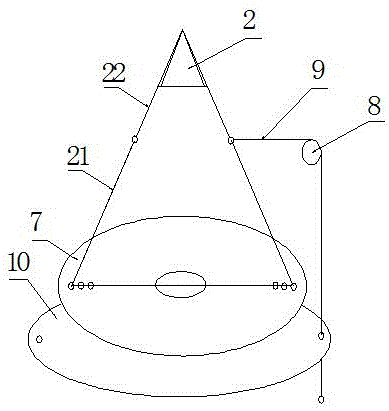

[0027] The invention discloses a three-dimensional fabric loom with conical and cylindrical shells. The device is mainly used for automatic weaving of three-dimensional fabrics with conical and cylindrical shells. see figure 1 and figure 2 , The three-dimensional textile loom with conical and cylindrical shells includes a main frame 1, and also includes a mandrel 2, a warp let-off mechanism, an opening mechanism, a weft insertion mechanism and a weft beating mechanism. The mandrel 2 is installed in the main frame 1, the let-off mechanism, the opening mechanism and the weft insertion mechanism are arranged on the periphery of the mandrel 2, and the beating-up mechanism is arranged on the mandrel 2. Since the three-dimensional fabric of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com