All-water environment-friendly and flame-retardant inflation memory polyurethane foam for automobile seat and preparation method of all-water environment-friendly and flame-retardant inflation memory polyurethane foam

A technology for polyurethane foam and car seats, applied in the field of flexible polyurethane foam, can solve the problems of insufficient reaction, reduced mechanical properties, and different sizes of foam cell structures, so as to improve safety and ride comfort, and solve the problem of reaction Inadequate, health-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

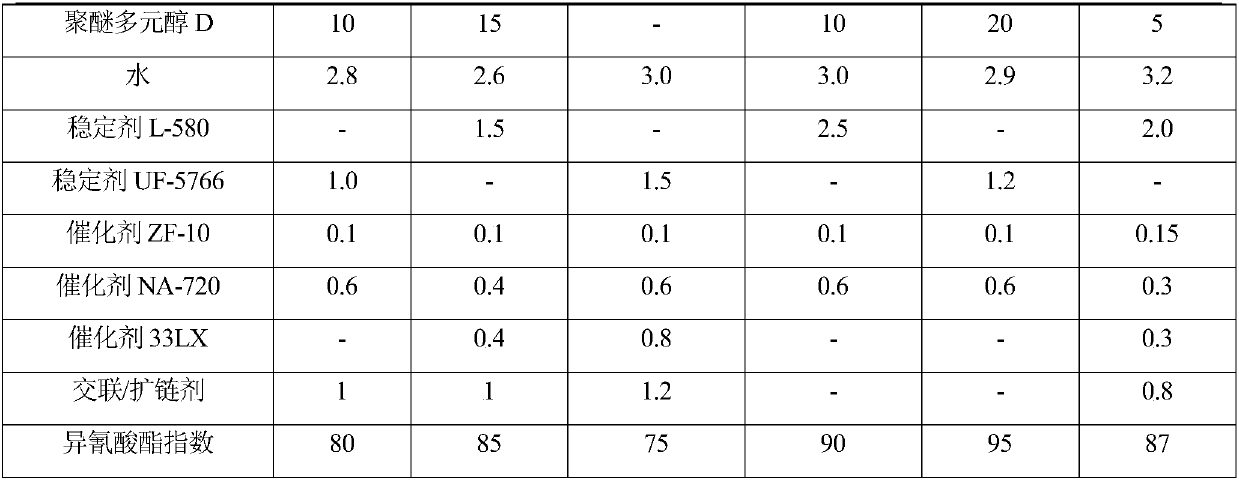

[0039] The present invention will be described in further detail below in conjunction with the examples, but the present invention is not limited to the following examples.

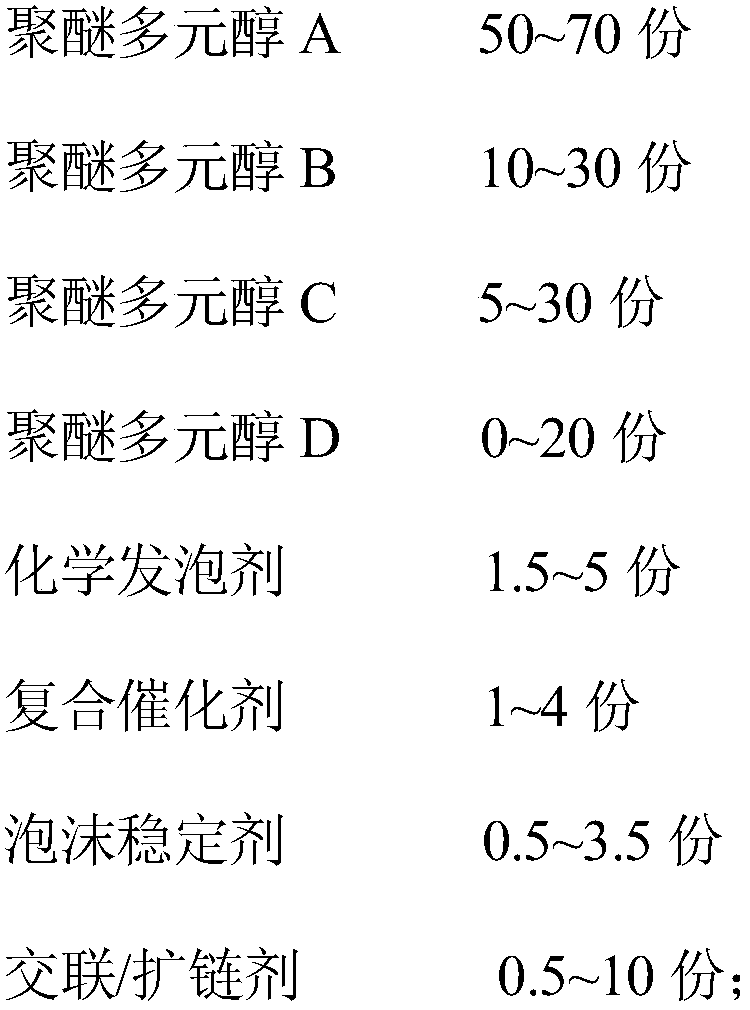

[0040]The car seat of following embodiment is used full water environmental protection flame-retardant type inflatable memory polyurethane foam, comprises following component, is specially:

[0041] Polyether polyol A is trifunctional, and glycerol (GLY) is used as an initiator. It is a copolymerized polyol formed by ring-opening polymerization of ethylene oxide and propylene oxide. The hydroxyl value is 42 mgKOH / g and the molecular weight is 4000.

[0042] Polyether polyol B is trifunctional, glycerol (GLY) is the initiator, and it is a copolymerized polyol formed by ring-opening polymerization with propylene oxide. The hydroxyl value is 225-245 mgKOH / g and the molecular weight is 700.

[0043] Polyether polyol C is a trifunctionality, trimethylolpropane (TMP) as the initiator, and a copolymerized polyol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com