A-grade non-ignitable heat insulating material and preparation method thereof

A technology of thermal insulation material and water retention agent, applied in the field of building materials, can solve the problems of high water absorption rate, large water absorption rate, high dry density of thermal insulation mortar, and achieve the effects of high durability, improved service life and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

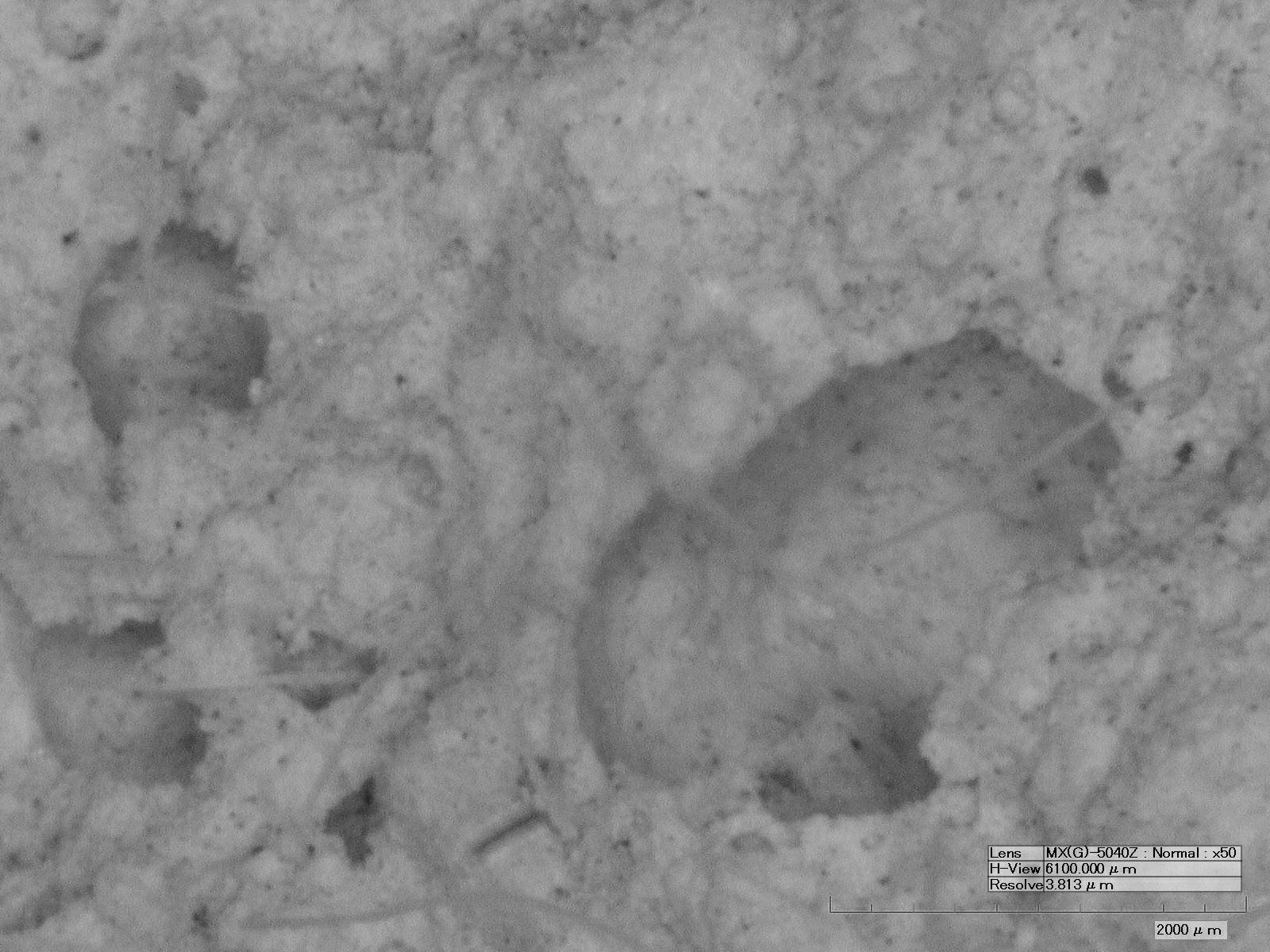

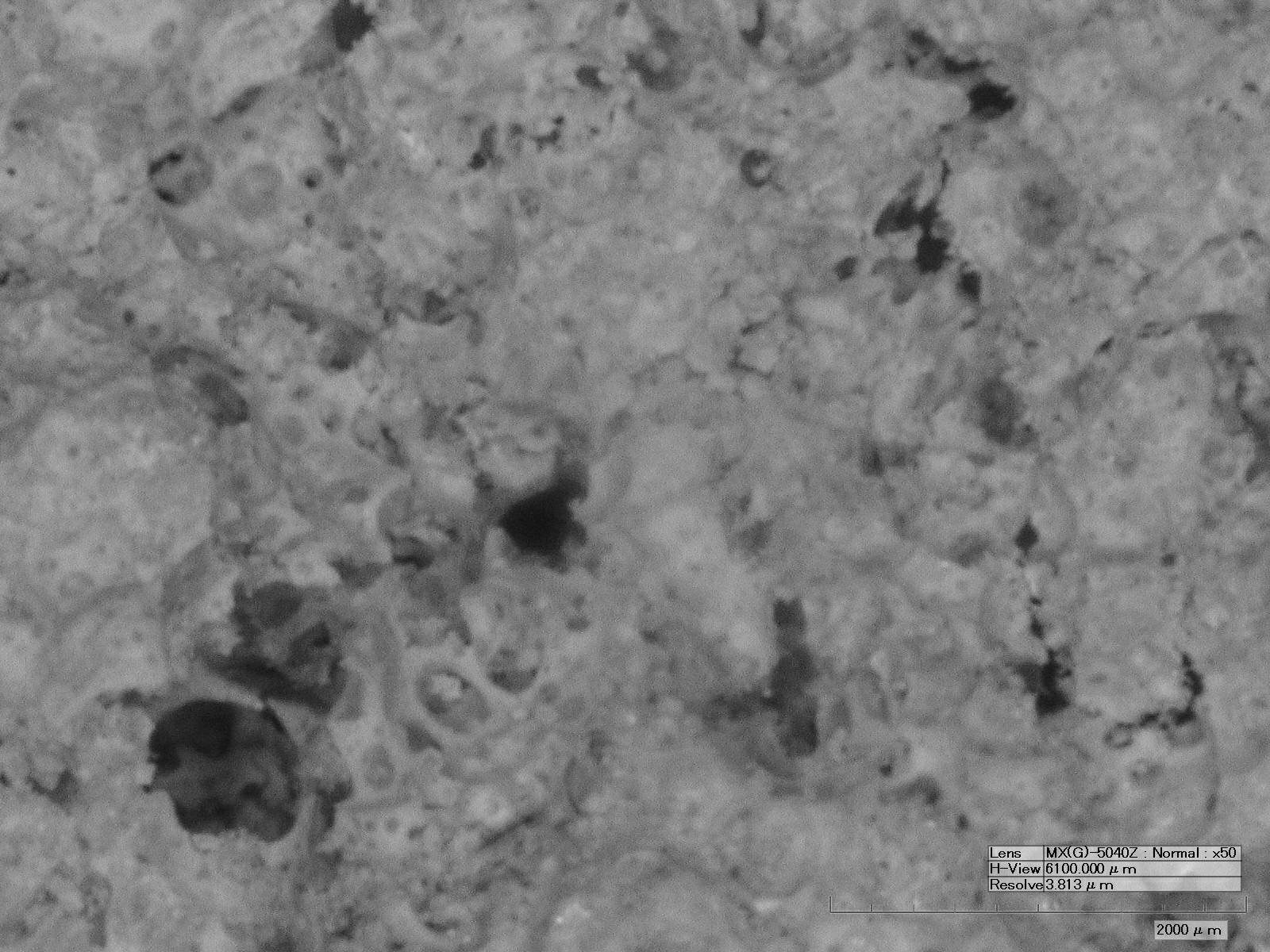

Image

Examples

Embodiment 1

[0047] 1) Pretreatment of cement: first grind ordinary portland cement and sulphoaluminate cement separately to make the specific surface area 3500cm 2 / g, be 4:1 to mix homogeneously by the mass ratio of the two;

[0048] 2) Modification of vitrified microbeads: Soak the vitrified microbeads in 30% emulsified paraffin for 5 hours, and dry them in an oven at 30°C for 2 hours to obtain the modified vitrified microbeads with a bulk density of 125kg / m 3 , the particle size is 0.50~2mm, and the volume water absorption rate is 30%;

[0049] 3) Preparation of mineral micropowder: kaolin was calcined at 800°C, kept for 4 hours, and ground to a specific surface area of 3000cm 2 / g, the obtained metakaolin and silica fume are mixed evenly in a mass ratio of 2:1, and ground to a specific surface area of 3500cm 2 / g.

[0050] 4) Preparation of the activator: mix the ground sodium hydroxide and sodium silicate, adjust the dosage of sodium hydroxide so that the modulus of the sodium...

Embodiment 2

[0057] 1) Pretreatment of cement: First, grind ordinary Portland cement and sulphoaluminate cement separately to make the specific surface area 3000cm 2 / g, mixed uniformly at a mass ratio of 5:1;

[0058] 2) Modification of vitrified microbeads: Soak the vitrified microbeads in 50% emulsified paraffin for 5 hours, and dry them in an oven at 35°C for 4 hours to obtain the modified vitrified microbeads; the bulk density is 130kg / m 3 , the particle size is 0.50~2mm, and the volume water absorption rate is 29%;

[0059] 3) Preparation of mineral micropowder: kaolin is calcined at 800°C, kept for 3 hours, and ground to a specific surface area of 3000cm 2 / g.

[0060] The obtained metakaolin and microsilica powder are mixed evenly in a mass ratio of 3:1, and ground to a specific surface area of 3000 cm 2 / g.

[0061] 4) Preparation of the activator: mix the ground sodium hydroxide and sodium silicate, adjust the dosage of sodium hydroxide so that the modulus of the sodium s...

Embodiment 3

[0067] 1) Pretreatment of cement: first grind ordinary portland cement and sulphoaluminate cement separately to make the specific surface area 4000cm 2 / g, be 4:1 to mix homogeneously by the mass ratio of the two;

[0068] 2) Modification of vitrified microbeads: Soak the vitrified microbeads in 45% emulsified paraffin for 4.5 hours, and dry them in an oven at 30°C for 3 hours to obtain the modified vitrified microbeads with a bulk density of 135kg / m 3 , the particle size is 0.5mm ~ 1.5mm, and the volume water absorption rate is 30%;

[0069] 3) Preparation of mineral micropowder: kaolin is calcined at 800°C, kept for 4 hours, and ground to a specific surface area of 3500cm 2 / g.

[0070] The obtained metakaolin and micro-silica powder are mixed evenly in a mass ratio of 2.5:1, and ground to a specific surface area of 3500 cm 2 / g.

[0071] 4) Preparation of the activator: mix the ground sodium hydroxide and sodium silicate, adjust the dosage of sodium hydroxide so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com