Organic silicon electronic-pouring sealant with high refractive index and high transparency, as well as preparation and application thereof

A technology with high refractive index and high transparency, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as poor mechanical properties and low light transmittance, and achieve the effects of fast speed, high refractive index, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

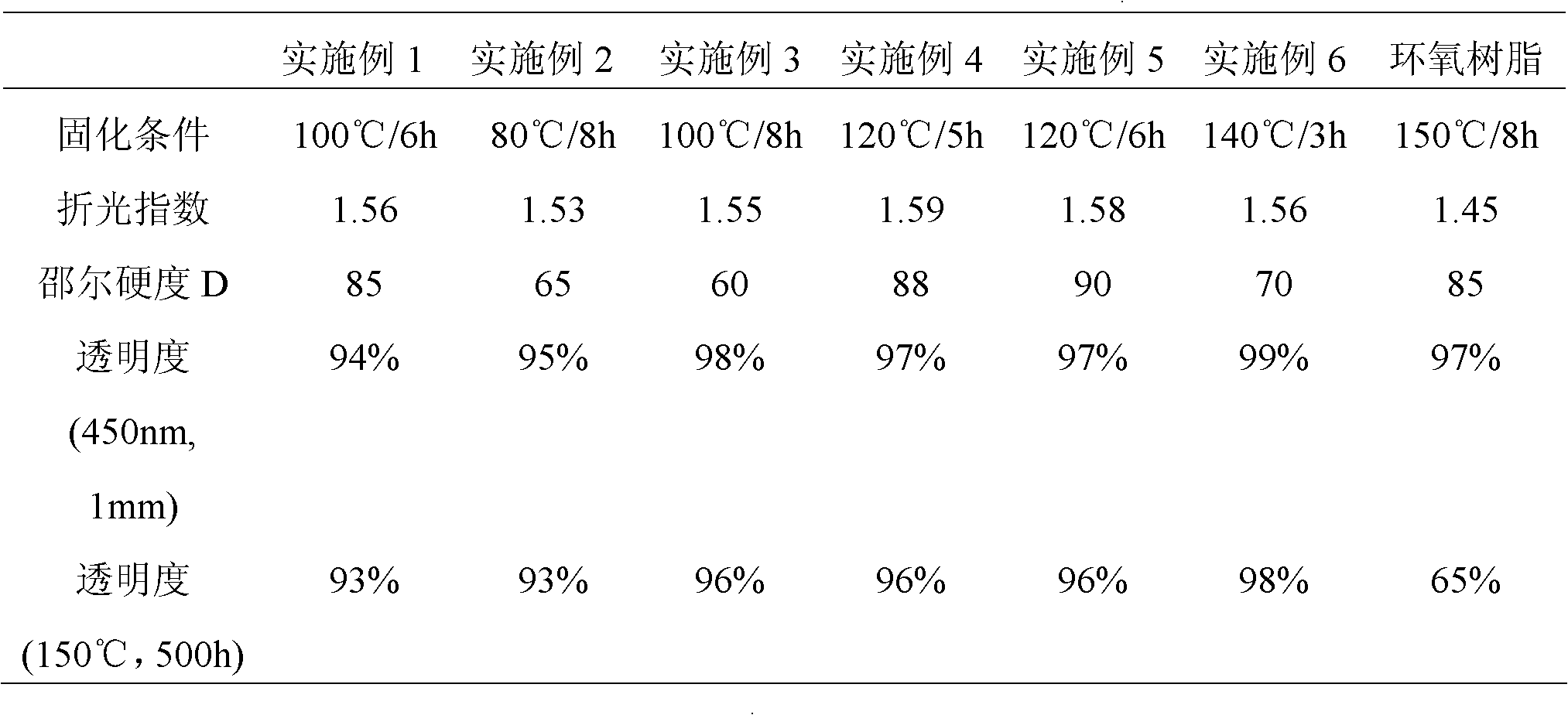

Examples

Embodiment 1

[0044] The preparation method of the silicone electronic potting compound with high refractive index and high transparency comprises the following steps:

[0045] (1) Mix 25 parts of methylvinyldimethoxysilane and 30 parts of ethylphenylsilanediol into 200 parts of o-xylene, add 3 parts of calcium hydroxide catalyst, heat up to 60°C for condensation After reacting for 10 hours, the solvent was distilled off to obtain an alkene-based silane oligomer precursor;

[0046] (2) Dissolve 60 parts of 3,4-methylbenzenedithiol and 30 parts of tetramethyltetravinylcyclotetrasiloxane in 200 parts of tetrahydrofuran respectively, that is, dissolve 60 parts of 3,4-methylbenzenedithiol in In 200 parts of tetrahydrofuran, 3,4-methylbenzenedithiol solution is obtained, and 30 parts of tetramethyltetravinyl cyclotetrasiloxane are dissolved in 200 parts of tetrahydrofuran to obtain tetramethyltetravinyl cyclotetrasiloxane solution; then First heat the 3,4-methylbenzenedithiol solution to 70°C, ...

Embodiment 2

[0051] The preparation method of the silicone electronic potting compound with high refractive index and high transparency comprises the following steps:

[0052] (1) Mix 30 parts of vinyltriethoxysilane and 25 parts of diethylsilanediol in 200 parts of p-xylene in proportion by weight, add 2 parts of triethylamine catalyst, heat up to 100 °C, Carrying out the condensation reaction for 3 hours, and distilling off the solvent to obtain an alkene-based silane oligomer precursor;

[0053] (2) Dissolve 60 parts of 4,4'-thiobisphenylthiol and 35 parts of tris(isoallyloxy)vinylsilane in 250 parts of N,N-dimethylformamide in proportion by weight In, 60 parts of 4,4'-thiobisbenzenethiol are dissolved in 250 parts of N,N-dimethylformamide to obtain 4,4'-thiobisbenzenethiol solution, and 35 parts of three ( Isoallyloxy) vinylsilane is dissolved in 250 parts of N,N-dimethylformamide to obtain tri(isoallyloxy)vinylsilane solution; then 4,4'-thiobisphenylthio Heat the alcohol solution to...

Embodiment 3

[0057] The preparation method of the silicone electronic potting compound with high refractive index and high transparency comprises the following steps:

[0058] (1) Mix 50 parts of vinyl tris (2-methoxyethoxy) silane and 35 parts of diisopropylsilanediol in 250 parts of dichloromethane, add 4 parts of potassium hydroxide catalyst, heat up to 50°C, carry out condensation reaction for 12 hours, distill off the solvent to obtain the precursor of olefin-based silane oligomer;

[0059] (2) Dissolve 40 parts of 1,3-propanedithiol and 40 parts of tetraallylsilane in 300 parts of ethanol respectively, that is, dissolve 40 parts of 1,3-propanedithiol in 300 parts of ethanol to obtain 1 , 3-propanedithiol solution, dissolve 40 parts of tetraallylsilane in 300 parts of ethanol to obtain a tetraallylsilane solution; then first heat the 1,3-propanedithiol solution to 60°C, and then Add the tetraallylsilane solution dropwise into the 1,3-propanedithiol solution, react at a constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com