Preparation method of injectable porous compound bone cement

A bone cement and injection technology, applied in the field of biomedical materials, can solve problems affecting the mechanical properties and biocompatibility of bone cement, and achieve the effect of reducing the elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

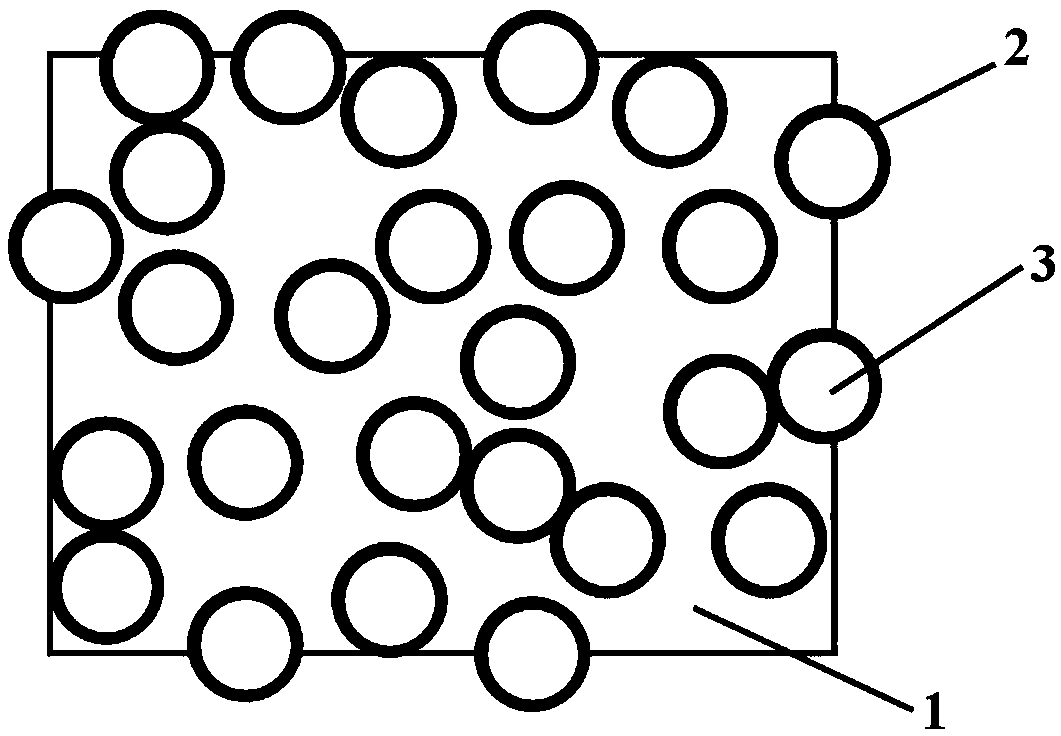

[0053] A preparation method of an injectable porous composite bone cement of the present invention, specifically comprising the following steps:

[0054] Step 1: Preparation of bioceramic hollow microspheres

[0055] Step 1.1: Take 5% to 20% of the ceramic powder and 80% to 95% of the distilled water according to the volume percentage. The sum of the volume percentages of the above components is 100%. Add the obtained ceramic powder into the distilled water and mix evenly to obtain a ceramic suspension. Turbid liquid; wherein, the ceramic powder is one or both of calcium phosphate bioceramics and bioglass; calcium phosphate bioceramics are hydroxyapatite (HA), β-tricalcium phosphate (β-TCP), phosphoric acid one of calcium;

[0056] Step 1.2: Take 97% to 99.5% of the ceramic suspension by mass percentage, and 0.5% to 3% of the binder. The sum of the mass percentages of the above components is 100%. Add the obtained binder to the ceramic suspension, Mix evenly to obtain a cera...

Embodiment 1

[0089] Step 1: Preparation of β-TCP hollow microspheres

[0090] Take 10ml of β-TCP powder and 90ml of distilled water; add β-TCP into distilled water and mix well to obtain β-TCP suspension; take 98g of β-TCP suspension and 2g of polyvinyl alcohol; add polyvinyl alcohol into β- TCP suspension, mixed evenly to obtain β-TCP impregnating slurry; take epoxy resin microspheres with a diameter of 600 μm, and dip them in β-TCP impregnating slurry for 6 times, and after each dipping, put them in the environment of 60°C Drying, and finally sintering at a temperature of 1300°C in the atmosphere for 1 hour to obtain β-TCP hollow microspheres;

[0091] Step 2: Preparation of injectable bone cement precursor

[0092] Take 0.051g of methyl methacrylate monomer, 0.0013g of N,N-dimethyl-p-toluidine, 0.0039g of hydroquinone, 78.9038g of methyl methacrylate-styrene copolymer, polymethyl methacrylate 15.78g, 5.26g of barium sulfate, and mix the above components evenly to obtain an injectable ...

Embodiment 2

[0098] Step 1: Preparation of Hydroxyapatite Hollow Microspheres

[0099] Take 5ml of hydroxyapatite powder and 95ml of distilled water; add hydroxyapatite to distilled water and mix well to obtain hydroxyapatite suspension; take 97g of hydroxyapatite suspension according to mass percentage, carboxymethyl cellulose 3 g; carboxymethyl cellulose was added to the hydroxyapatite suspension, and mixed evenly to obtain a hydroxyapatite impregnating slurry; phenolic resin microspheres with a diameter of 300 μm were impregnated in the hydroxyapatite impregnating slurry for 10 After each impregnation, it was dried in an environment of 60°C, and finally sintered at a temperature of 1250°C in the atmosphere for 2 hours to obtain hydroxyapatite hollow microspheres;

[0100] Step 2: Preparation of injectable bone cement precursor

[0101] Take 0.05g of methyl methacrylate monomer, 0.001g of N,N-dimethyl-p-toluidine, 0.003g of hydroquinone, 82.946g of methyl methacrylate styrene copolymer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com