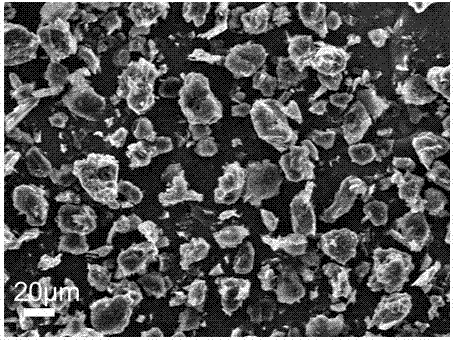

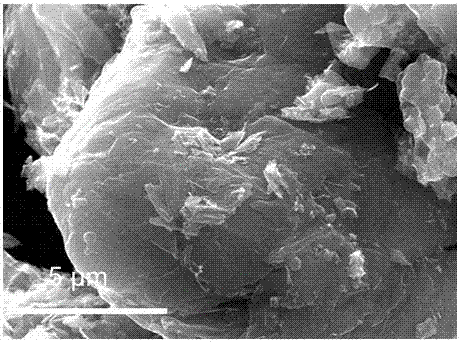

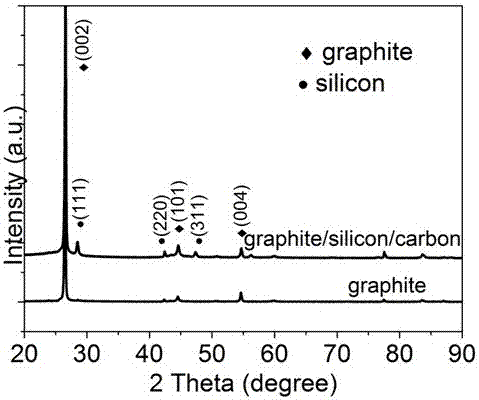

Graphite/silicon@carbon core-shell structure composite spherical cathode material and preparation method thereof

A negative electrode material and composite spherical technology, which is applied in the field of graphite/silicon@carbon lithium ion battery composite spherical negative electrode material and its preparation, can solve the problems affecting the first Coulomb efficiency and cycle stability of silicon electrode materials, and the reversible capacity fading of silicon materials. , the collapse of the silicon material structure and other problems, to reduce the irreversible capacity, improve the charging and discharging efficiency, and improve the electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Take 0.7gD 50 Nano-silicon with a particle size of 100nm is added to 30g of N-methylpyrrolidone, and 0.07g of polyvinylpyrrolidone is added as a dispersant, ultrasonically dispersed in a 25ml beaker for 30min and then transferred to a 200ml beaker; the working frequency is 25Hz, the ultrasonic power 350W;

[0046] (2) Add 10g of flake graphite to step (1), and add a small amount of surfactant and high-viscosity polymer to the nano-silicon suspension, and stir on a magnetic stirrer for 2 hours at a speed of 1000rpm;

[0047] (3) After the above steps are stirred, transfer the beaker to an oil bath at 100°C and stir until the solution is completely evaporated to dryness at a speed of 600rpm;

[0048] (4) Use a granulator to pelletize the material obtained in step (3) to obtain a spherical silicon@graphite skeleton precursor;

[0049] (5) Dissolve 5g of asphalt in 20g of tetrahydrofuran, add 3g of stearic acid to adjust the viscosity, add the spherical silicon@graphi...

Embodiment 2

[0057] (1) Take 1.6gD 50 Particle size is 150nm nano-silicon joins in 50g n-butanol, and adds 0.3g hexadecyltrimethylammonium bromide as dispersant, transfers in the beaker of 200ml after ultrasonic dispersion 40min in the beaker of 50ml; The frequency is 30 Hz, and the ultrasonic power is 500 W; the subsequent steps are the same as in Example 1, except that phenolic resin is used as the organic carbon source, and ethanol is used as the solvent.

[0058] The steps and test conditions for making the battery are the same as in Example 1.

Embodiment 3

[0060] (1) Take 0.9gD 50 Nano-silicon with a particle size of 200nm is added to 30g of ethylene glycol, and 0.1g of sodium lauryl sulfate is added as a dispersant, ultrasonically dispersed in a 25ml beaker for 30min and then transferred to a 200ml beaker; the working frequency is 25Hz, Ultrasonic power is 350W;

[0061] (2) Add 25g of graphite flakes to step (1), add a small amount of surfactant and high-viscosity polymer to the nano-silicon suspension, and stir on a magnetic stirrer for 2 hours at a speed of 1000rpm;

[0062] (3) After the above steps are stirred, transfer the beaker to an oil bath at 110°C and stir until the solution is completely evaporated to dryness at a speed of 800rpm;

[0063] (4) Use a granulator to pelletize the material obtained in step (3) to obtain a spherical silicon@graphite skeleton precursor;

[0064] (5) Dissolve 10g of furfural resin in 30g of xylene, add 5g of stearic acid to adjust the viscosity, add the graphite / silicon spherical skelet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com