Nano-particle material surface modification method

A nanoparticle and surface modification technology, applied in the field of materials science, can solve problems such as hindering quantum dot materials, and achieve the effect of less dosage, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

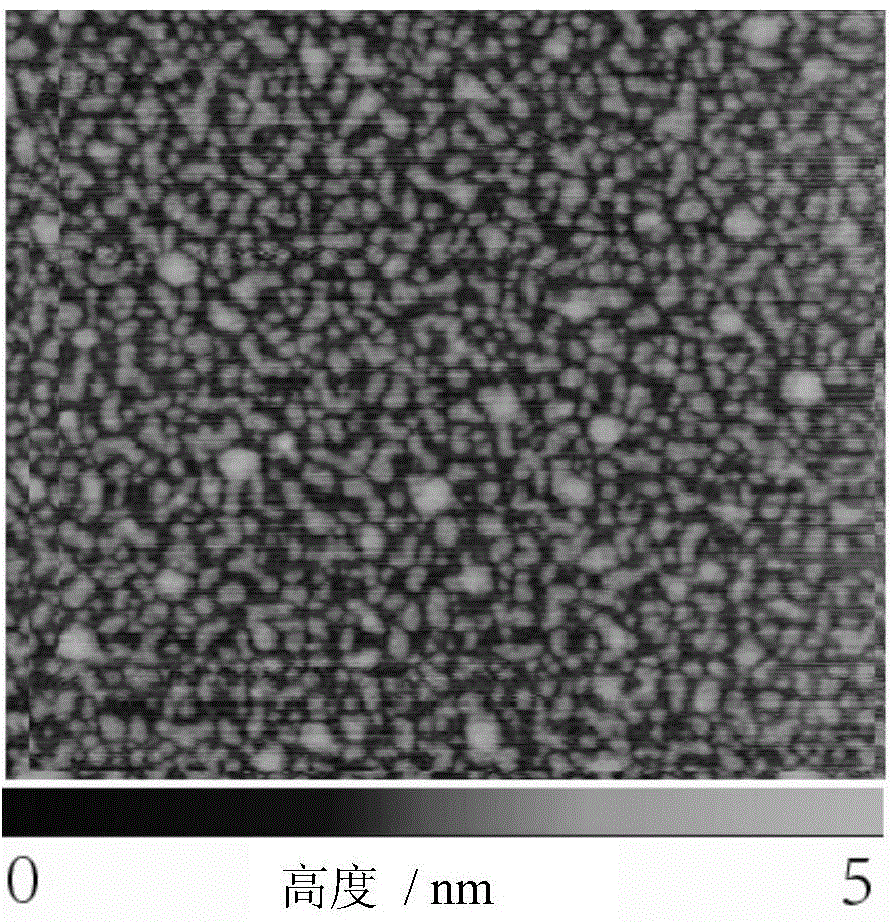

[0030] Tungsten oxide (WO) whose surface ligand is dodecylamine 3 ) quantum dots (particle size about 2nm), add 4ml of pyridine, after ultrasonic dispersion for 10min, N 2 Heating and stirring at 80° C. for 4 h under atmosphere, adding 5 ml of petroleum ether after cooling to room temperature, and centrifuging to obtain pyridine-coated tungsten oxide quantum dots.

Embodiment 2

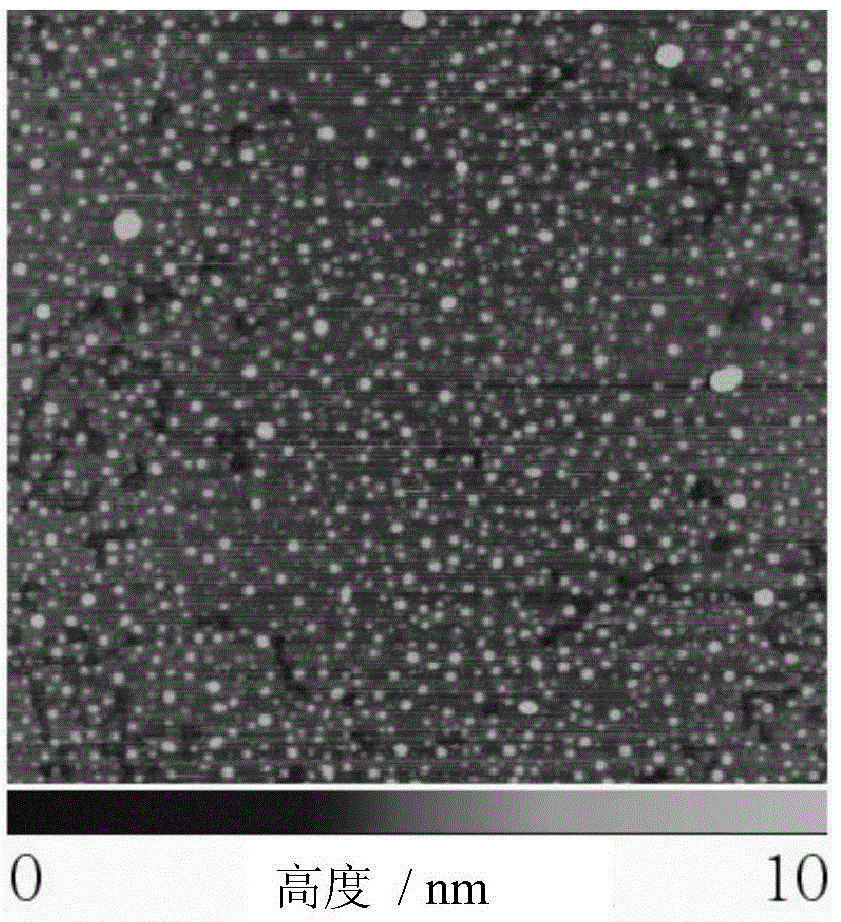

[0034] Cadmium sulfide (CdS) quantum dots (particle size about 5nm) whose surface ligand is tri-n-octylphosphine oxide were added to 5ml of aniline, and after ultrasonic dispersion for 10min, N 2 Heating and stirring at 120° C. for 6 h under protection, adding 5 ml of petroleum ether after cooling to room temperature, and centrifuging to obtain aniline-coated cadmium sulfide quantum dots.

Embodiment 3

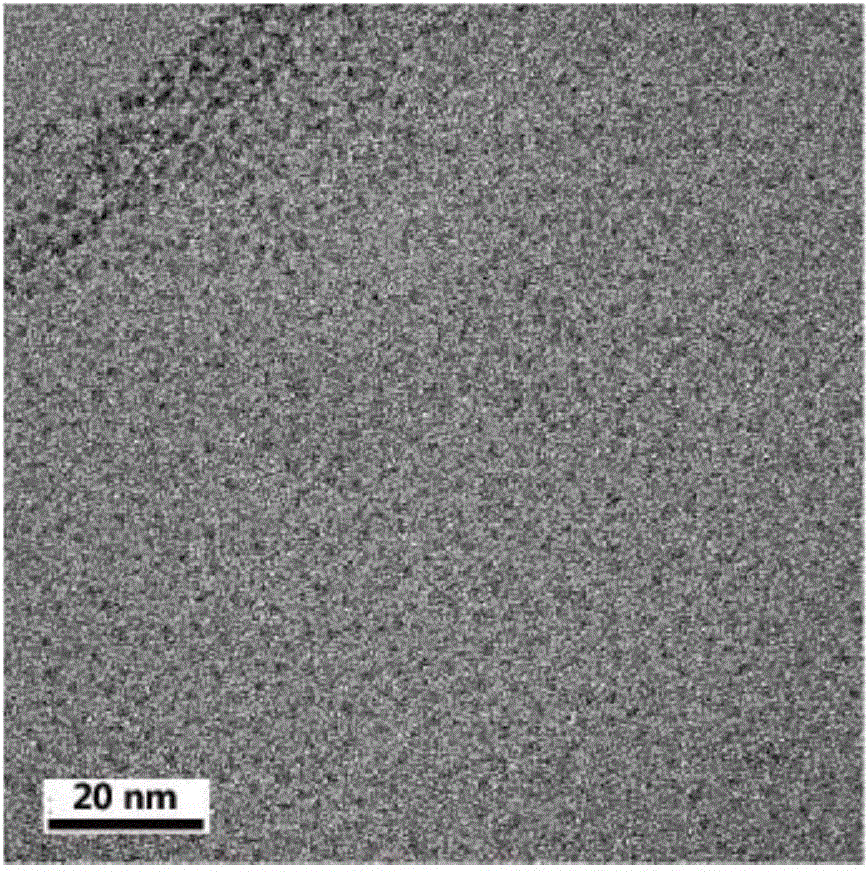

[0036] Add cadmium telluride (CdTe) nanocrystals (particle size about 10nm) with oleic acid as the ligand on the surface, add 8ml of mercaptoacetic acid, ultrasonically disperse for 5min, heat and stir at 50°C for 4h under air atmosphere, add 5ml of toluene after cooling to room temperature , CdTe nanocrystals coated with thioglycolic acid were obtained by centrifugation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com