Preparation method of graphene-grafted polypyrrole nanotube/sulfur composite material for positive electrode of lithium-sulfur battery

A technology of polypyrrole nanotubes and lithium-sulfur batteries, applied in battery electrodes, lithium batteries, nanotechnology for materials and surface science, etc., can solve the problems of battery coulombic efficiency decline, electrolyte consumption, and low specific surface area. Effects of shortening ion transmission distance, improving electrical conductivity, and improving wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

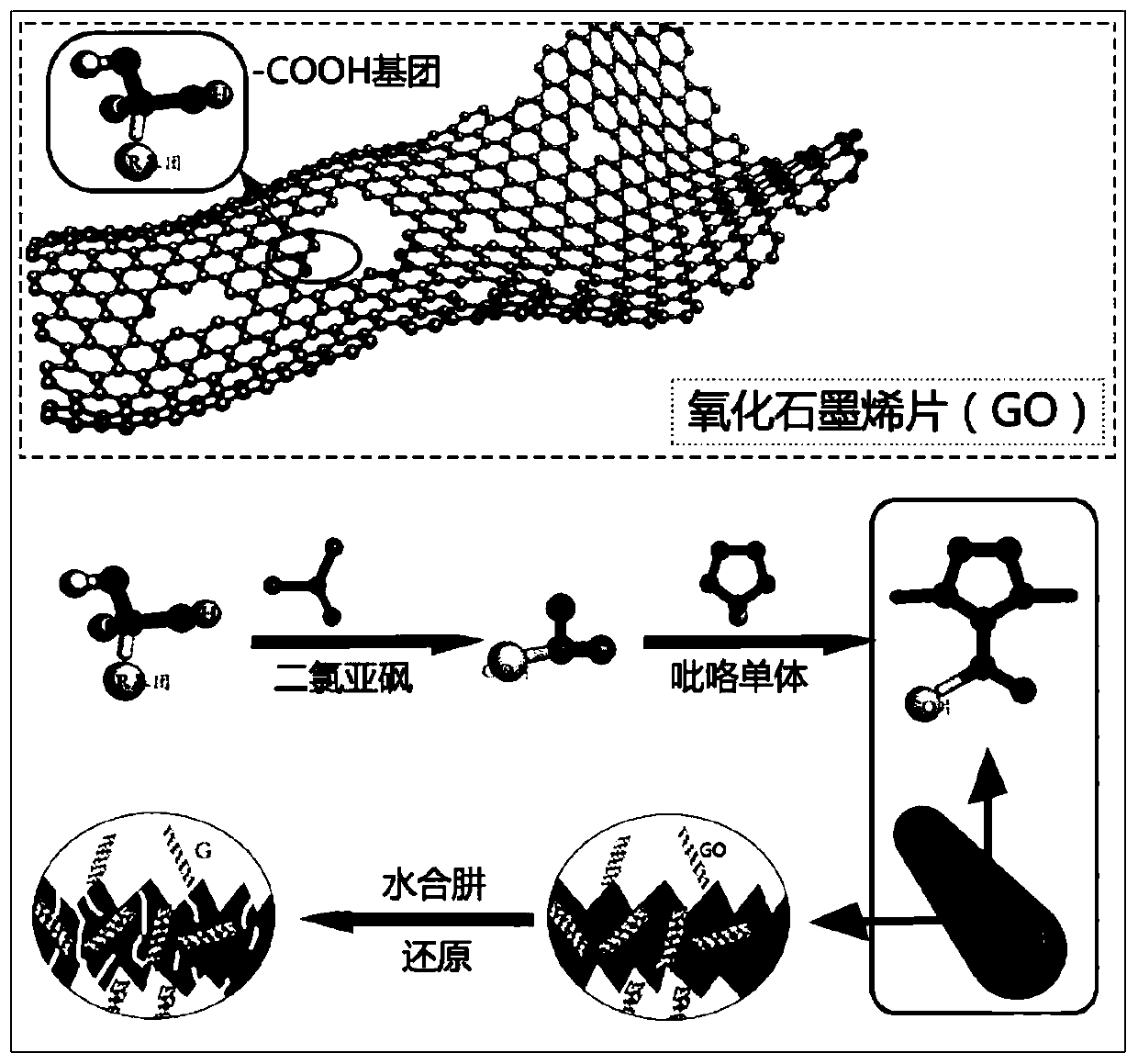

[0050] The first step is to prepare graphene oxide grafted polypyrrole (GOppy) nanotubes:

[0051] (1) Weigh 50mg of graphite oxide powder, grind it and place it in 2mL DMF for ultrasonic dispersion for 30 minutes, pour the dispersed graphite oxide (GO) solution into a three-necked flask, add 10mL of thionyl chloride to it, ice bath and stir After the reaction is completed for 2 hours, in an oil bath at 80°C, the nitrogen pipe goes deep into the bottom of the reaction solution, and the residual thionyl chloride is blown dry with nitrogen, and then 48 mL of deionized water is added to obtain graphene oxide containing acid chloride groups Aqueous solution; (2) Take 100mL (0.66mg / mL) methyl orange aqueous solution, add 0.5mL pyrrole, and ultrasonically disperse for 30min, then add 50mL acid chloride group-containing graphene oxide aqueous solution, and ultrasonically disperse for 30min at 200rpm Treated in an ice bath for 30 min under the stirring condition of the temperature at -5°...

Embodiment 2

[0065] Others are the same as in Example 1, except that in the first step, ammonium persulfate (APS) is used instead of ferric chloride as the initiator. The performance of the obtained material is close to that of Example 1.

Embodiment 3

[0067] Others are the same as in Example 1, except that the mass ratio of graphene grafted polypyrrole (Gppy) nanotubes to nano sulfur powder in the third step is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com