CNTs@SiO2@Ni/Al-LDH shell structure three-dimensional nanometer material and preparation method thereof

A three-dimensional nanotechnology, core-shell structure technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as poor electrical conductivity, poor electrochemical performance, and easy agglomeration of hydrotalcite nanosheets , to achieve the effect of avoiding stacking, enhancing activity, and good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

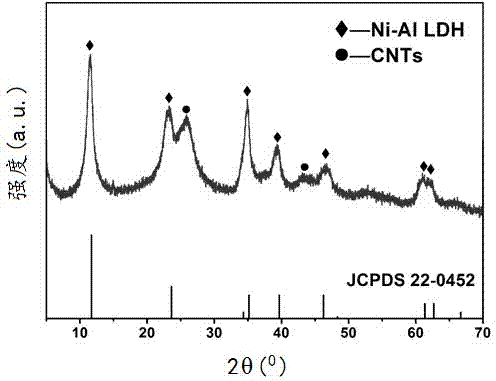

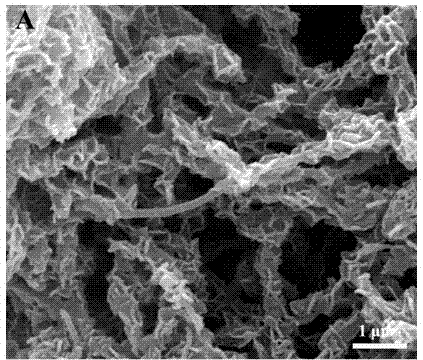

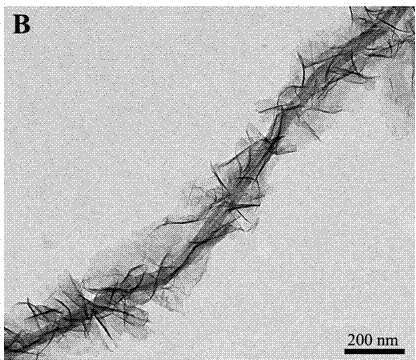

[0032] Carbon nanotube silica nickel aluminum hydrotalcite (CNTsSiO 2 Preparation of three-dimensional nanostructured materials with Ni / Al-LDH) core-shell structure.

[0033]1) Take 0.01g of carbon nanotubes and 0.01g of CTAB in a container, then add 0.01L of ethanol and 0.01L of deionized water to the above container, and perform ultrasonic treatment on the above mixed solution to obtain carbon nanotube solution A;

[0034] 2) Add 0.1ml NaOH and 0.1ml tetraethyl orthosilicate (TEOS) to solution A, stir evenly, centrifuge, wash the product with ethanol and dry it, and finally obtain clean powder B.

[0035] 3) Disperse 0.1g aluminum isopropoxide in 0.1L deionized water, stir evenly at 30°C, add HNO dropwise to the upper system solution 3 Adjust the pH value of the solution to 8, continue stirring evenly, then cool the solution system to room temperature, and obtain the AlOOH sol after the water evaporates. Grind the dried AlOOH, add 0.01L of deionized water, stir evenly and ...

Embodiment 2

[0040] 1) Take 0.01 g of carbon nanotubes and 0.6 g of CTAB in a container, then add 0.1 L of ethanol and 0.1 L of deionized water to the above container, and perform ultrasonic treatment on the above mixed solution to obtain carbon nanotube solution A;

[0041] 2) Add 0.2ml NaOH and 0.2ml tetraethyl orthosilicate (TEOS) to solution A, stir evenly, centrifuge, wash the product with ethanol and dry it, and finally obtain clean powder B.

[0042] 3) Disperse 0.2g aluminum isopropoxide in 0.2L deionized water, after stirring evenly, add HNO dropwise to the upper system solution 3 Adjust the pH value of the solution to 7, continue stirring evenly, then cool the solution system to room temperature, and obtain the AlOOH sol after the water evaporates. Grind the dried AlOOH, add 0.1L of deionized water, stir evenly and reflux for 5 hours to obtain solution C.

[0043] 4) Take 50ml of solution C and 0.02g of powder B, stir evenly, centrifuge or filter the product, wash with alcohol, ...

Embodiment 3

[0047] 1) Take 0.03 g of carbon nanotubes and 2 g of CTAB in a container, then add 0.2 L of ethanol and 0.2 L of deionized water to the container, and perform ultrasonic treatment on the above mixed solution for 6 hours to obtain a carbon nanotube solution A;

[0048] 2) Add 5ml NaOH and 5ml tetraethyl orthosilicate (TEOS) into solution A, stir evenly, centrifuge, wash the product with ethanol and dry it, and finally obtain clean powder B.

[0049] 3) Disperse 2g aluminum isopropoxide in 0.5L deionized water, stir evenly, add HNO dropwise to the upper system solution 3 Adjust the pH value of the solution to 6, continue stirring evenly, then cool the solution system to room temperature, and obtain the AlOOH sol after the water evaporates. Grind the dried AlOOH, add 0.5L of deionized water, stir evenly and reflux for 7 hours to obtain solution C.

[0050] 4) Take 100ml of solution C and 30g of powder B, stir for 1-48 hours, centrifuge or filter the product, wash with alcohol, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com