Composition for manufacturing radiation cross-linking thermoplastic olefin elastomer foam and manufacturing method for radiation cross-linking thermoplastic olefin elastomer foam using the same

A thermoplastic olefin and radiation cross-linking technology, which is applied in the field of a composition for preparing radiation-cross-linked thermoplastic olefin elastomer foam and the preparation of radiation-cross-linked thermoplastic olefin elastomer foam by using the composition, which can solve pollution sources, generate environment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

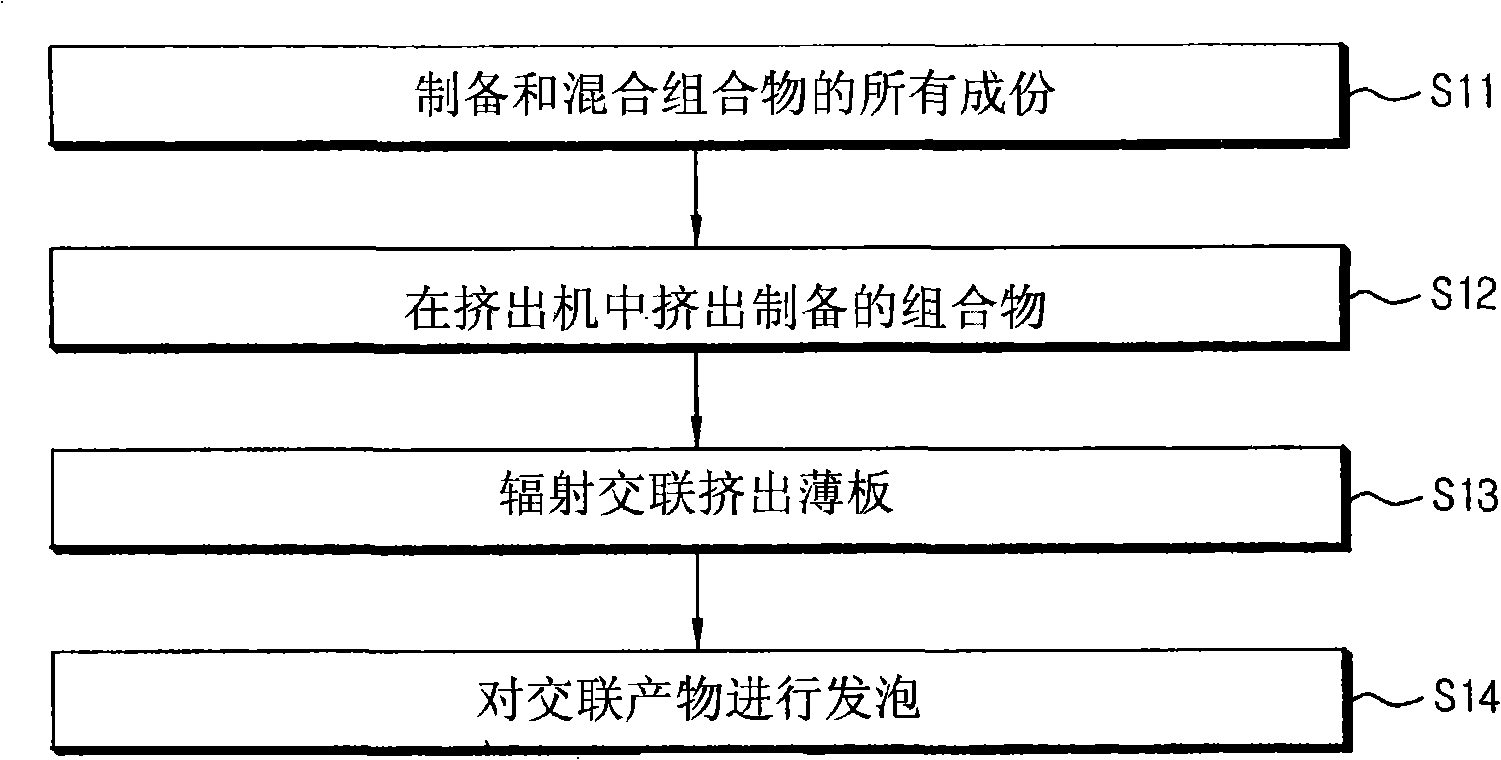

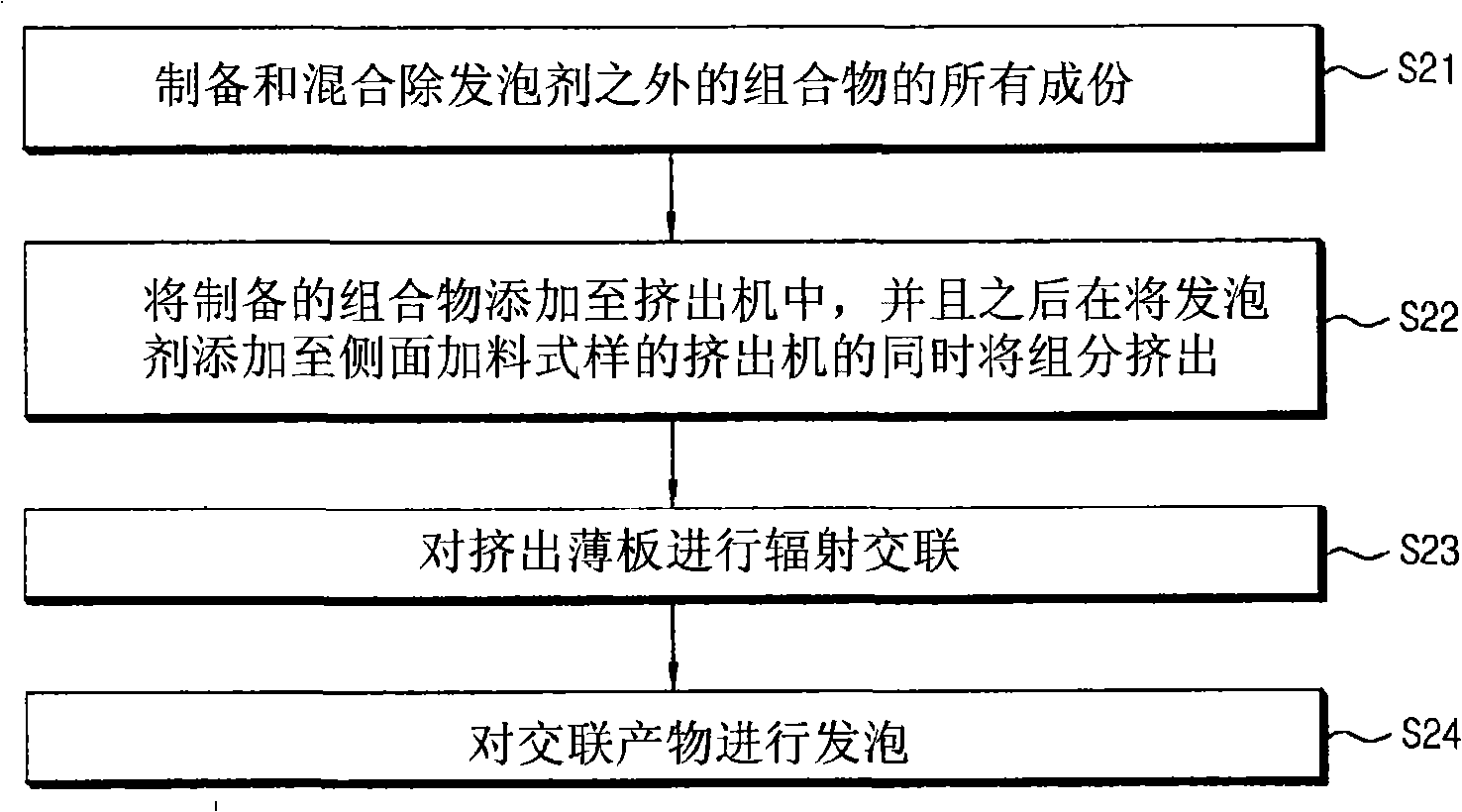

[0037] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the description made here is only a preferred embodiment for the purpose of illustrating the present invention and does not limit the scope of the present invention, so it should be understood that other etc. can be made without departing from the spirit and scope of the present invention Efficient substitutions and changes.

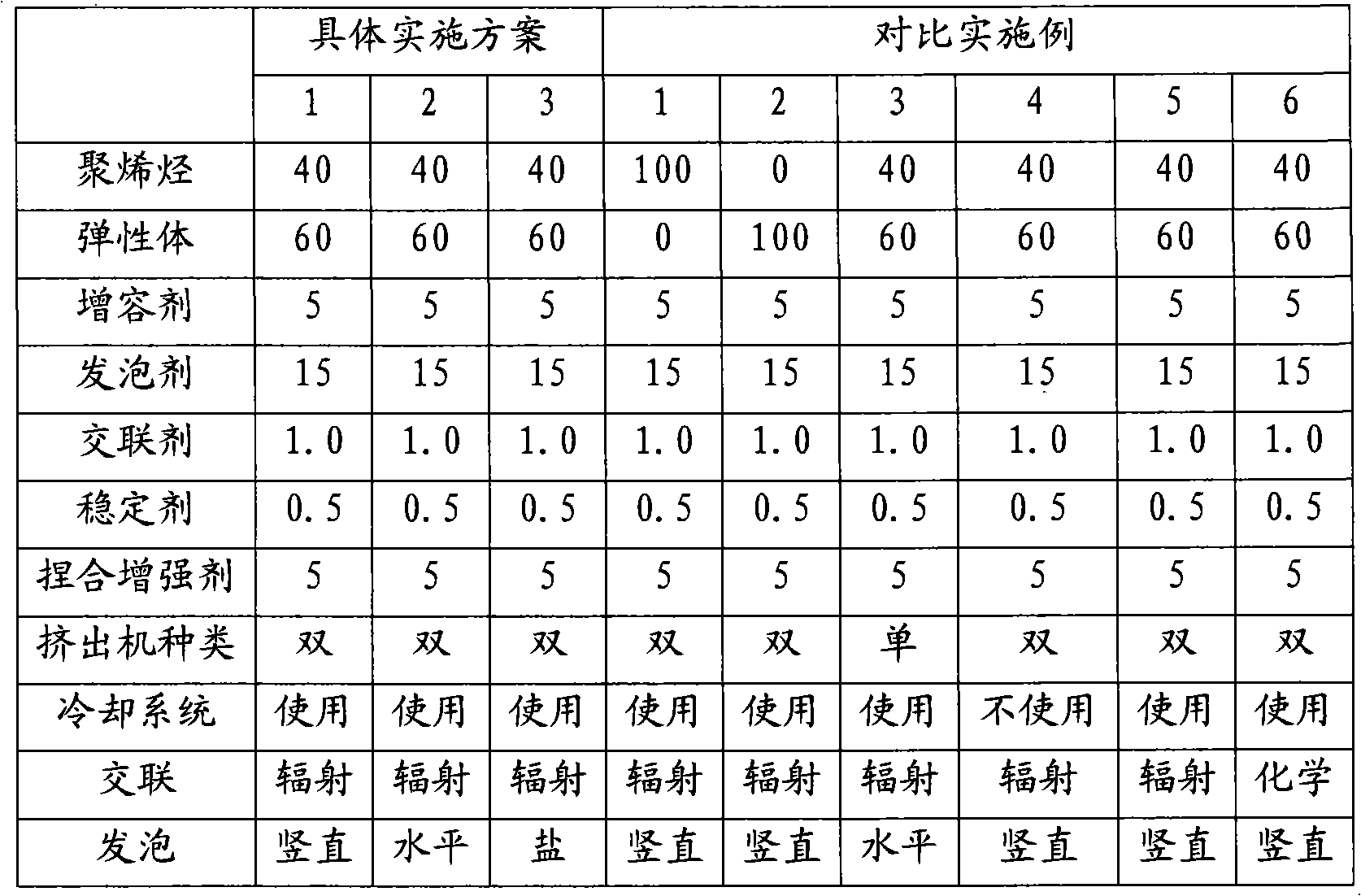

[0038] As listed in Table 1 below, each composition is classified into In specific embodiments 1 to 3 and comparative examples 1 to 3.

[0039] Table 1

[0040]

[0041] In table 1, use polypropylene resin as the high hardness polyolefin resin of the hard segment of forming base material, use EPDM as the elastomer of the soft segment of forming base material, use the EPDM (from DuPont) of grafting 0.9% maleic anhydride commercially available) as a compatibilizer, ADCA as a blowing agent, an acrylic com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com