Waterproof and corrosion-resistant sheath material of degaussing cable and production method thereof

A technology for degaussing cables and sheath materials, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of large specific weight, poor flexibility of cables, and easy cracking of cables, and achieve good mechanical properties and good water absorption resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

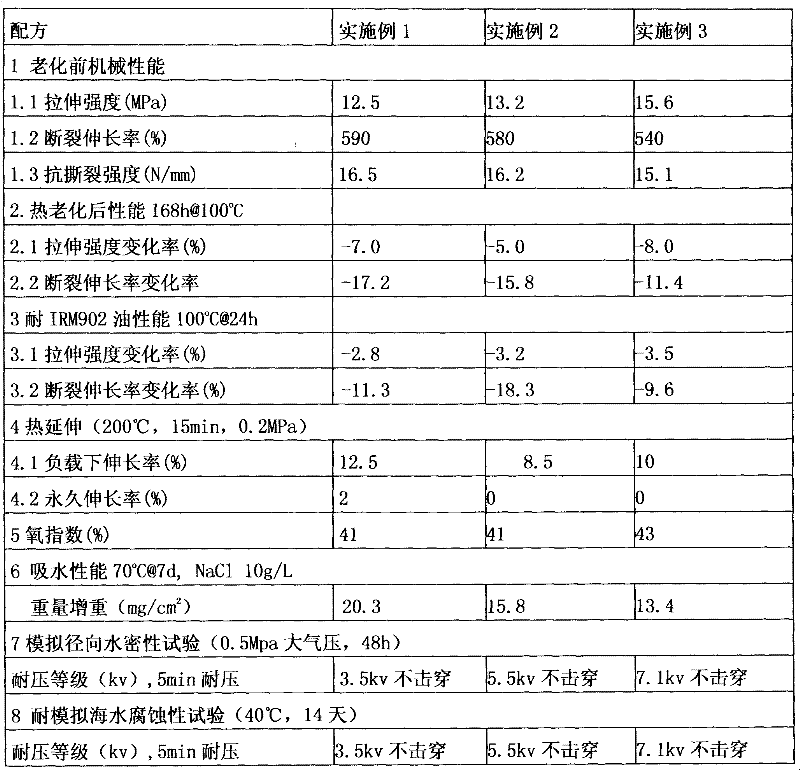

Examples

Embodiment 1

[0020] A waterproof and corrosion-resistant sheath material for degaussing cables, comprising the following components: 100 parts of neoprene rubber, 10 parts of ZnO, 10 parts of magnesium oxide, 0.5 parts of vulcanization accelerator DM, 5 parts of vulcanization aid NA-22, reinforcement SiO 2 30 parts, anti-aging agent ODA 5 parts, plasticizer chlorinated paraffin 15 parts, flame retardant antimony trioxide 20 parts, filler compound system 90 parts, coupling agent A172 1 part, processing aid vaseline 6 parts, 2 parts stearic acid.

[0021] The preparation method of the waterproof and corrosion-resistant sheath material of the degaussing cable comprises the following steps:

[0022] 1. Add the neoprene rubber to the torque rheometer and mix evenly, then add stearic acid, reinforcing agent and filler, plasticizer, coupling agent, processing aid, anti-aging agent ODA, and processing aid vaseline in sequence , Flame retardant antimony trioxide, MgO, vulcanization aid NA-22, vul...

Embodiment 2

[0026] A waterproof and corrosion-resistant sheath material for degaussing cables, comprising the following components: 100 parts of neoprene, 5 parts of ZnO, 5 parts of magnesium oxide, 1 part of vulcanization accelerator DM, 1 part of vulcanization aid NA-22, and reinforcing agent SiO 2 40 parts, antiaging agent ODA 2 parts, plasticizer chlorinated paraffin 10 parts, flame retardant antimony trioxide 10 parts, filler compound system 50 parts, compound coupling agent 5 parts, processing aid vaseline 2 parts, hard Fatty acid 2 parts.

[0027] The preparation method of the waterproof and corrosion-resistant sheath material of the degaussing cable comprises the following steps:

[0028] 1. Add chloroprene rubber to the torque rheometer and mix evenly, then add stearic acid, reinforcing agent and filler, plasticizer, coupling agent, processing aid, anti-aging agent ODA, and processing aid vaseline in sequence , Flame retardant antimony trioxide, MgO, vulcanization aid NA-22, vul...

Embodiment 3

[0032] A waterproof and corrosion-resistant sheath material for degaussing cables, comprising the following components: 100 parts of neoprene, 2 parts of ZnO, 3 parts of magnesium oxide, 5 parts of vulcanization accelerator DM, 0.5 parts of vulcanization aid NA-22, and reinforcing agent SiO 2 15 parts, 1 part of antioxidant ODA, 5 parts of plasticizer chlorinated paraffin, 5 parts of flame retardant antimony trioxide, 120 parts of filler compound system, 3 parts of compound coupling agent, 3 parts of compound processing aid, 2 parts stearic acid.

[0033] The preparation method of the waterproof and corrosion-resistant sheath material of the degaussing cable comprises the following steps:

[0034] 1. Add chloroprene rubber to the torque rheometer and mix evenly, then add stearic acid, reinforcing agent and filler, plasticizer, coupling agent, processing aid, anti-aging agent ODA, and processing aid vaseline in sequence , Flame retardant antimony trioxide, MgO, vulcanization a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com