Polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene, can solve the problems of high shrinkage, difficult to achieve high strength, high density, etc., and achieve the effect of energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

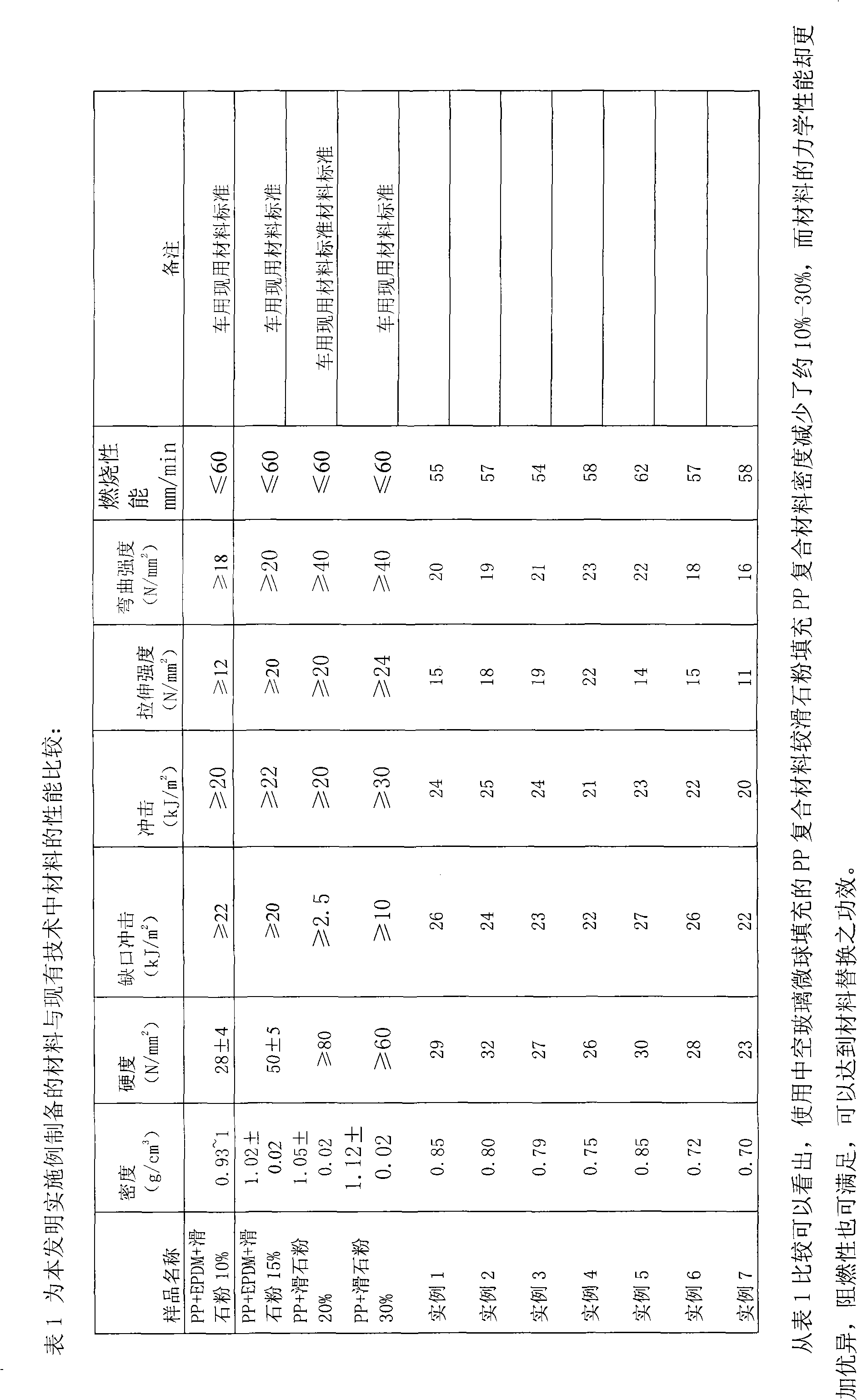

Examples

Embodiment 1

[0047] Weigh raw materials according to the following formula: (kg)

[0048] Polypropylene 70, POE 10, hollow glass microsphere 10, titanium dioxide 0.5, silane coupling agent KH570 2, POE grafted maleic anhydride 3, stearic acid 1, antimony trioxide 1, decabromodiphenylethane 2.5 .

[0049] The hollow glass microspheres are selected: the hollow glass microspheres of the 3M company model M30K.

[0050] Preparation:

[0051] (1) 70 kg of polypropylene, 10 kg of POE, 10 kg of hollow glass microspheres, 0.5 kg of titanium dioxide, 2 kg of silane coupling agent KH570, 3 kg of POE grafted maleic anhydride, and 1 kg of stearic acid 1 kg of antimony, 2.5 kg of decabromodiphenylethane, accurately weighed according to the formula for later use;

[0052] (2) Soak 10 kilograms of hollow glass microspheres in 2 kilograms of silane coupling agent KH570 for 30 minutes to obtain surface-treated hollow glass microspheres with good compatibility;

[0053] (3) Place the surface-treated holl...

Embodiment 2

[0056] Weigh raw materials according to the following formula: (kg)

[0057] Polypropylene 65, EPDM 10, SBS 3, hollow glass microsphere 15, antioxidant 1010 1.5, silane coupling agent KH5501, EPDM grafted maleic anhydride, 0.5, stearic acid 0.5, PE wax 1, silicone rubber 0.5, three Antimony oxide 1, MCA 1.

[0058] The hollow glass microspheres are hollow glass microspheres of S60SH model of 3M Company.

[0059] Preparation:

[0060](1) 65 kilograms of polypropylene, 10 kilograms of EPDM, 3 kilograms of SBS, 15 kilograms of hollow glass microspheres, 1.5 kilograms of antioxidant 1010, 1 kilogram of silane coupling agent KH550, 0.5 kilogram of EPDM grafted maleic anhydride, stearic acid 0.5 kg, PE wax 1 kg, silicone rubber 0.5, antimony trioxide 1 kg, MCA 1 kg, weighed accurately according to the formula for later use;

[0061] (2) Soak 15 kg of hollow glass microspheres in 1 kg of silane coupling agent KH550 for 10 min to obtain surface-treated, compatible hollow glass micr...

Embodiment 3

[0067] Weigh raw materials according to the following formula: (kg)

[0068] Polypropylene 60, POE 2, EPDM 8, hollow glass microsphere 17, titanium dioxide 1, antioxidant CPL (caprolactam) 2.5, silane coupling agent KH560 1, PP grafted maleic anhydride 3, PE wax 0.3, silicone rubber 0.2 , antimony trioxide 5.

[0069] The preparation method is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com