Flame-retardant PP/nylon corrugated tube composite material and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, applied in the field of corrugated pipe materials, can solve the problem that there are no reports of flame-retardant polypropylene/nylon corrugated pipe composite materials and their preparation methods, high price of nylon material corrugated pipes, and bellows pipes. Poor mechanical properties and other problems, to achieve the effect of easy industrial production, excellent flame retardant performance and bending performance, and good electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

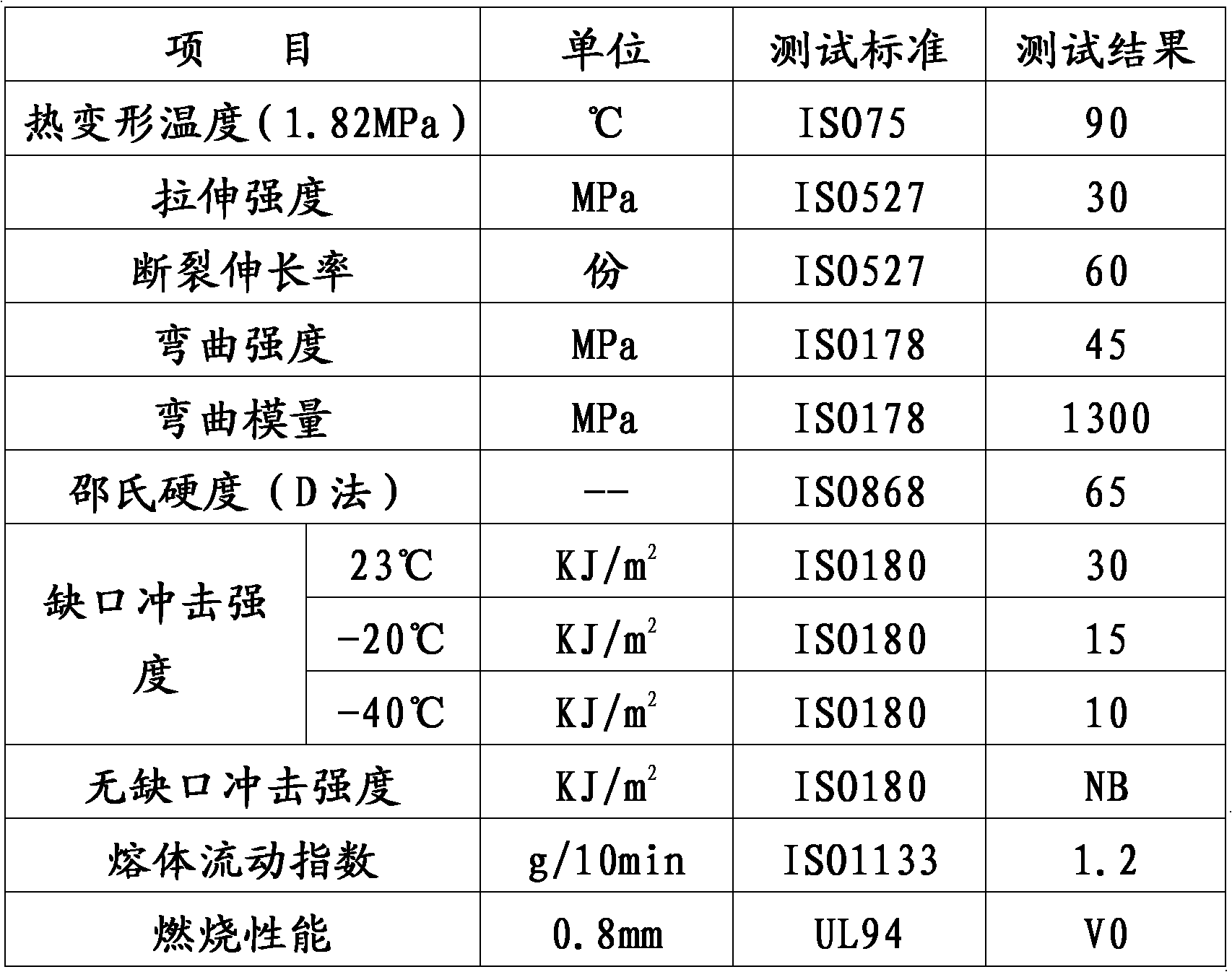

Embodiment 1

[0041] 1. Preparation of filler masterbatch:

[0042] 27 kg of polypropylene powder with a melt flow index of 1.2 g / 10 min and 30 kg of a mixture of particulate inorganic filler-calcium carbonate and aluminum silicate whiskers with an average particle size of 3 microns were pre-mixed evenly, and then 0.2 1 kg of thermal stabilizer Irganox 1010 and 0.2 kg of processing aids are then melted and granulated in a twin-screw extruder at a processing temperature of 140 to 250°C; filled masterbatches are made for use in the following examples.

[0043] 2. Preparation of flame retardant polypropylene / nylon composite material:

[0044] 60 kg of polypropylene, 25 kg of nylon 6, 10 kg of compatibilizer-maleic anhydride grafted polypropylene PP-g-MAH, 5 kg of toughening agent-EPDM, 2 kg of filler masterbatch, 15 kg of decabromodi Phenylethane, 5 kg of antimony trioxide, 0.2 kg of heat stabilizer and 0.3 kg of processing aid are added to a twin-screw extruder with a length-to-diameter rati...

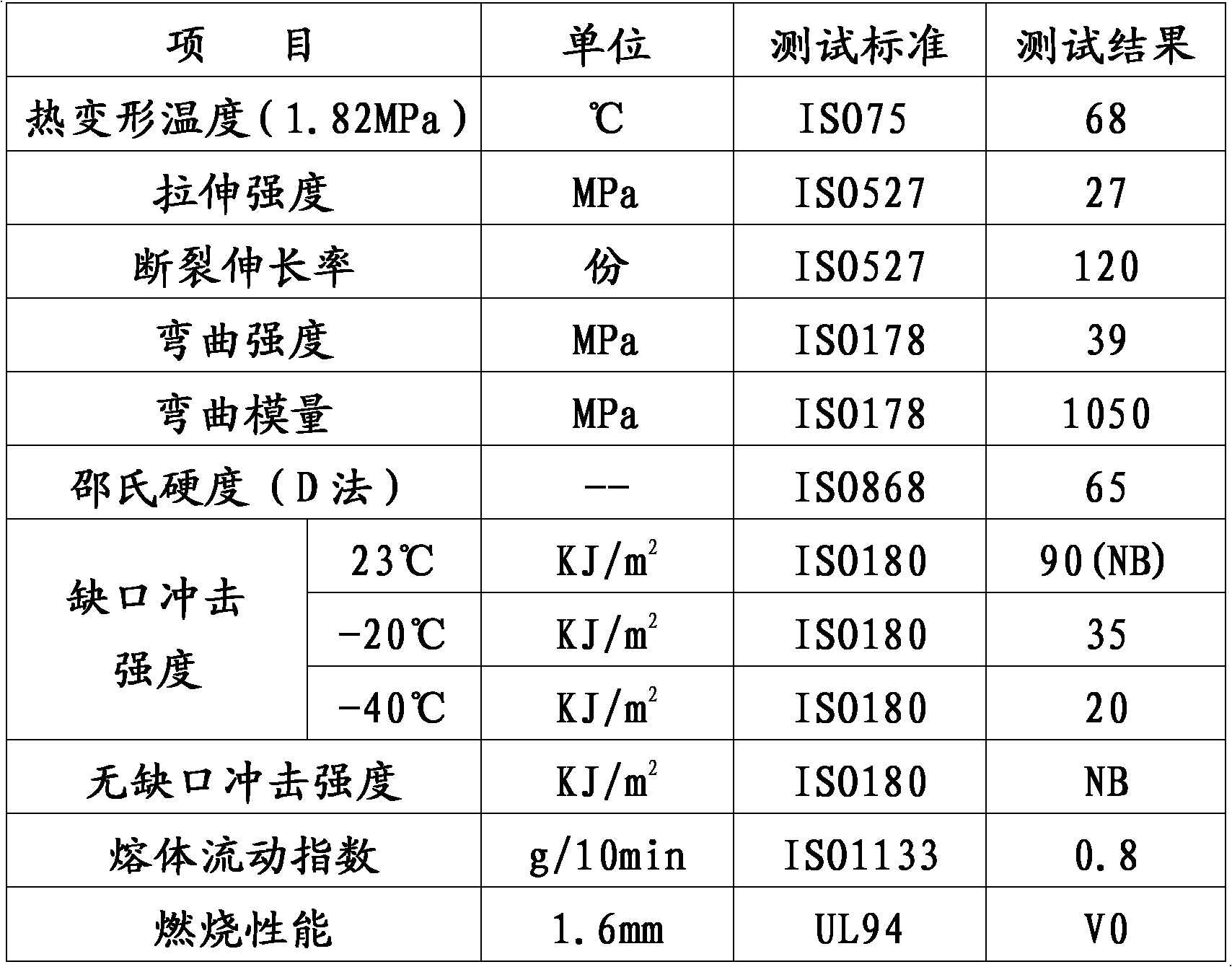

Embodiment 2

[0049] Compatibilizer-maleic anhydride grafted POE (POE-g-MAH), 5 kilograms of toughening agent-POE, 3 kilograms of filling masterbatches prepared by 60 kilograms of polypropylene, 25 kilograms of nylon 6,5 kilograms , 0.2 kg of heat stabilizer, 10 kg of octabromo-S ether and 0.3 kg of processing aid are added into a twin-screw extruder with a length-to-diameter ratio of 40:1, melted and mixed at 230°C, extruded and granulated, and obtained This embodiment 2 flame-retardant PP / PA composite material.

[0050] The flame-retardant PP / PA composite material prepared in this example has high toughness, excellent impact resistance, flame retardancy and high heat distortion temperature, and has good surface gloss, good chemical corrosion resistance, and UV aging and abrasion resistance, electrical insulation performance is greater than 400MΩ, the performance test results are shown in Table 2:

[0051] Flame-retardant PP / PA composite material properties prepared in Table 2 Example 2

...

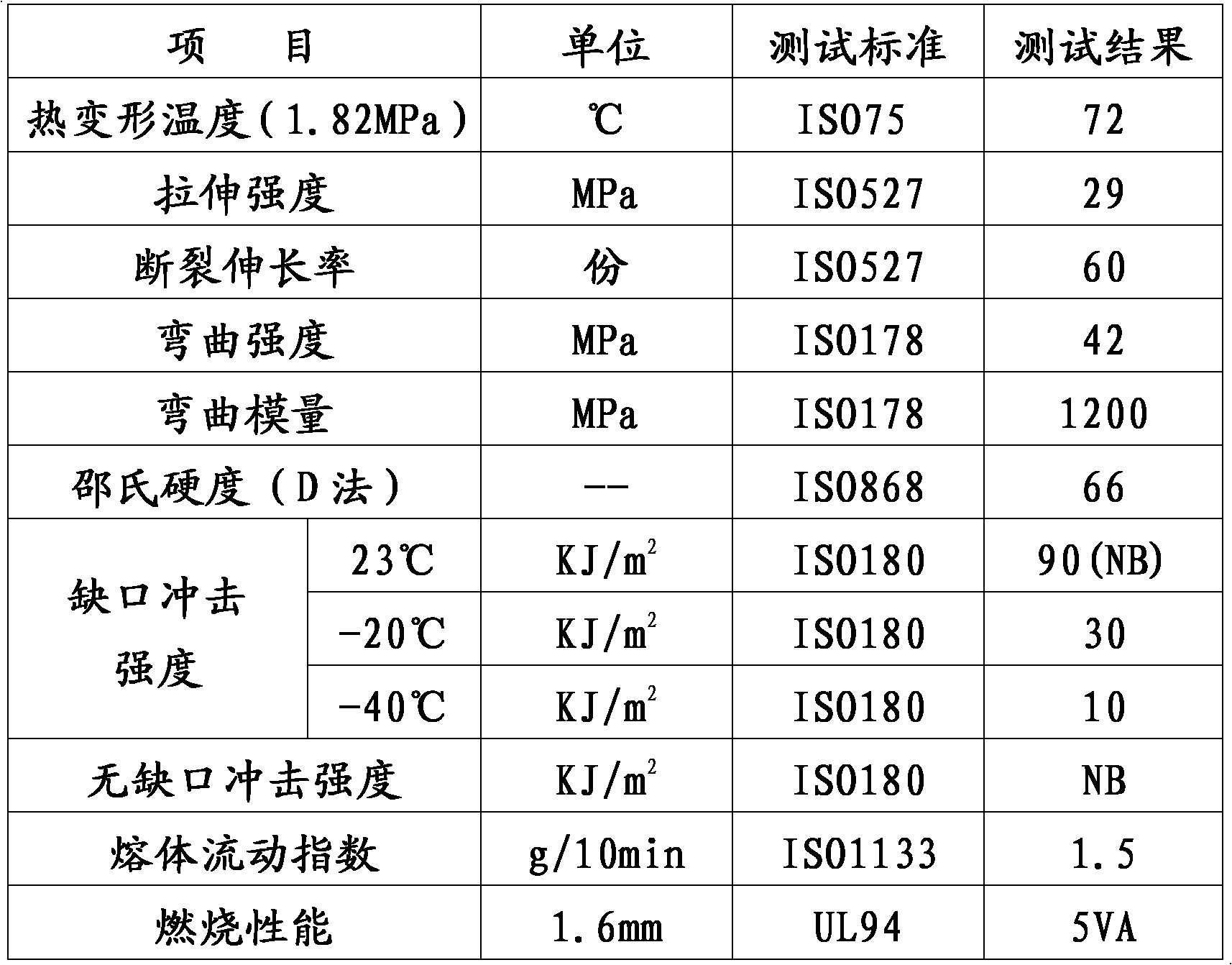

Embodiment 3

[0054] Compatibilizer-maleic anhydride grafted POE (POE-g-MAH), 5 kilograms of toughening agent-TPV, 2 kilograms of filling masterbatches prepared by embodiment 1 of 60 kilograms of polypropylene, 25 kilograms of nylon 6,5 kilograms , 10 kg of decabromodiphenylethane, 5 kg of octabromoether, 5 kg of antimony trioxide, 0.2 kg of heat stabilizer, and 0.5 kg of processing aids are added into a twin-screw extruder with a length-to-diameter ratio of 40:1 In the machine, carry out melt mixing and dispersion at 230°C, extrude and granulate, and prepare the flame-retardant PP / PA composite material of Example 3.

[0055] The flame-retardant PP / PA composite material prepared in this example has high toughness, excellent impact resistance and high heat distortion temperature, and has good surface gloss, good chemical corrosion resistance, UV aging resistance and Wear resistance performance, electrical insulation performance is greater than 200MΩ, the specific performance is shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com