Grease-proof low-smoke halogen-free flame-proof cable material

A flame-retardant cable and oil-resistant technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor oil resistance and low-smoke halogen-free flame retardant materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

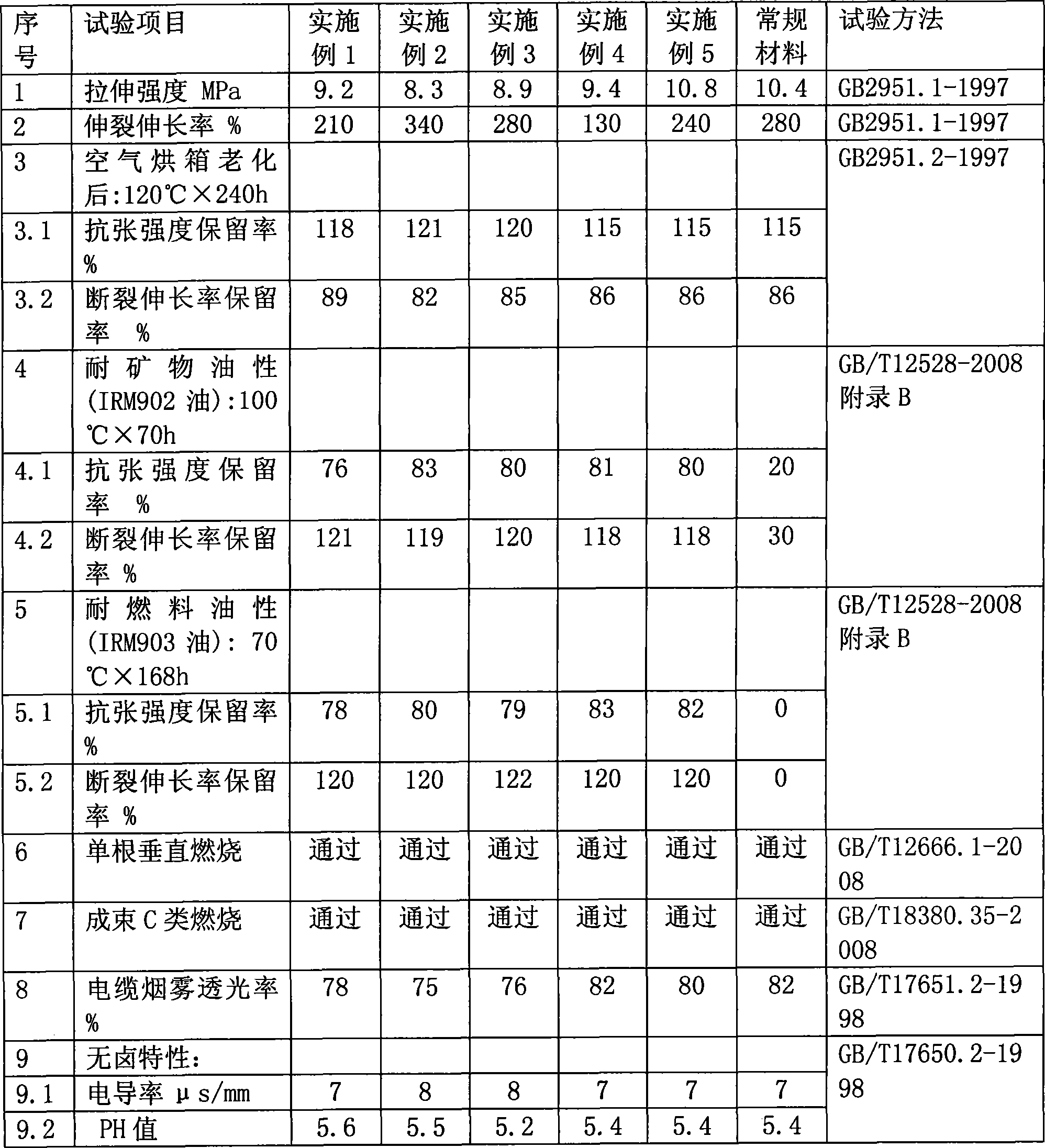

Examples

Embodiment 1

[0025] Base material ethylene-vinyl ester copolymer: 25Kg, flame retardant: surface-treated magnesium hydroxide 32.5Kg, surface-treated red phosphorus 1.25Kg, zinc borate 2.5Kg, antimony trioxide 1.25Kg, antioxidant: 1010, 0.25Kg, DLTP 0.25Kg, crosslinking sensitizer TAIC, 0.75Kg, processing aid stearic acid 1.25Kg, colorant carbon black 0.25Kg.

[0026] The above raw materials are respectively placed in a mixer for mixing and stirring, then internally kneaded by a banbury mixer, twin-screw extruded and granulated, processed into wires, and cross-linked by radiation.

Embodiment 2

[0028] Base material ethylene-acid vinyl ester copolymer: 12.75Kg, base material nitrile rubber: 12.25Kg, flame retardant: surface-treated magnesium hydroxide 7.5Kg, surface-treated red phosphorus 1.5Kg, zinc borate 2.5Kg, polyphosphoric acid Ammonium 13.75Kg, antioxidant: 1010, 0.5Kg, cross-linking sensitizer TMPTMA, 1.5Kg, processing aid paraffin 0.5Kg, colorant carbon black, 8.75Kg.

[0029] The above raw materials are respectively placed in a mixer for mixing and stirring, then internally kneaded by a banbury mixer, twin-screw extruded and granulated, processed into wires, and cross-linked by radiation.

Embodiment 3

[0031] Base material ethylene-acid vinyl ester copolymer: 17.5Kg, base material nitrile rubber: 7.5Kg, flame retardant: surface-treated aluminum hydroxide 20Kg, surface-treated magnesium hydroxide 10Kg, surface-treated red phosphorus 2.5Kg, Zinc borate 2.5Kg, ammonium polyphosphate 2.5Kg, antioxidant: 1010, 1Kg, crosslinking sensitizer triallyl cyanurate, 1.5Kg, processing aid stearic acid 1Kg, colorant carbon black 7.5Kg.

[0032] The above raw materials are respectively placed in a mixer for mixing and stirring, then internally kneaded by a banbury mixer, twin-screw extruded and granulated, processed into wires, and cross-linked by radiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com