Flame retardant leather, preparation method and application

A technology of leather and parts by weight, which is applied in the direction of textiles and papermaking, can solve the problems of halogen flame retardants, deterioration of flame retardant performance, weak force, etc., and achieve widening flame retardant temperature range, large specific surface area, and reduced use volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of flame retardant leather top layer:

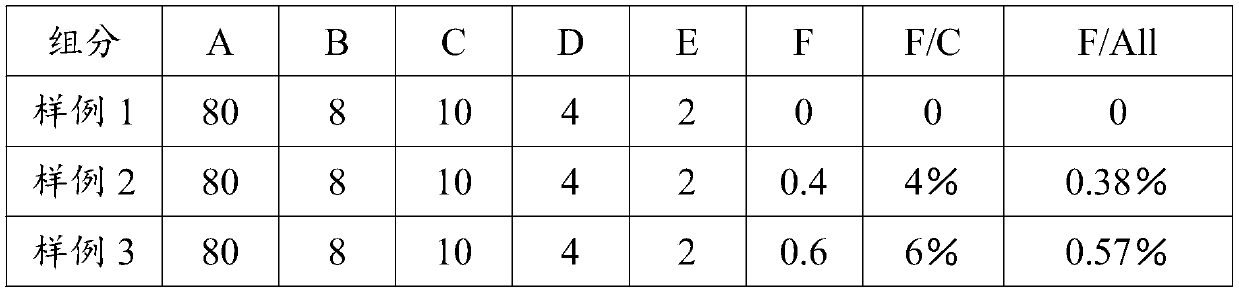

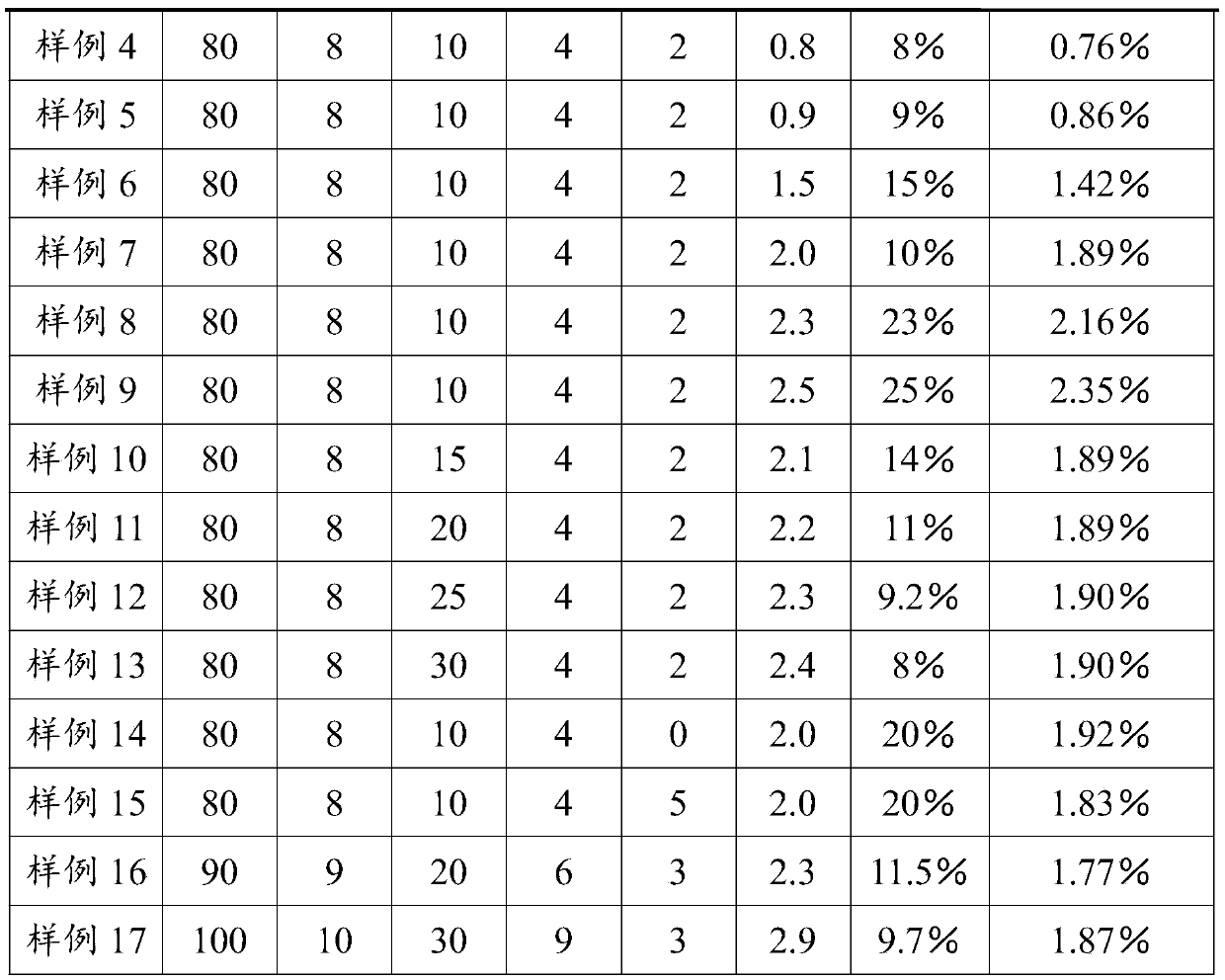

[0043] Take 80-100 parts of organic silica gel, 8-10 parts of hardener, and 10-30 parts of modified layered double metal hydroxide to form a primary slurry;

[0044] Use 4-9 parts of high-viscosity simethicone oil with a viscosity value of 100-300mPa·s / 25°C to adjust the viscosity of the primary slurry to 100000-120000mPa·s / 25°C to form a secondary slurry;

[0045] Get a certain amount of modified nano-silica and mix it into the secondary slurry to form a third slurry, the parts by weight of the modified nano-silica and the modified layered double metal hydroxide The ratio of parts by weight is not less than 8%, and the ratio of parts by weight of the modified nano-silica to the total parts by weight is not more than 1.9%;

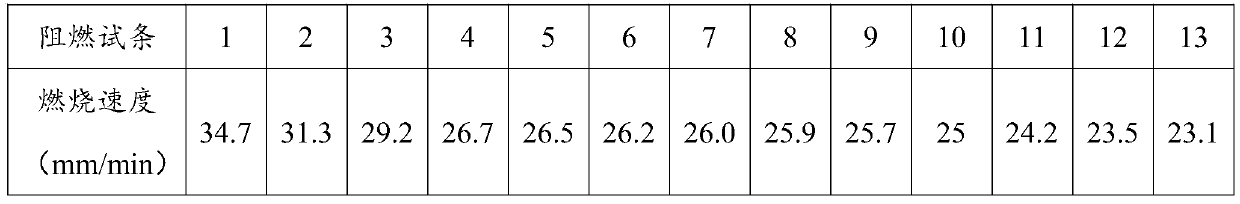

[0046] Coat the three-time slurry on the surface of the release paper / film with a coating thickness of 0.1mm, and then input it into a multi-stage temperature difference oven. The multi-stage temp...

Embodiment 2

[0071] In this embodiment, the modified layered double metal hydroxide used in this application will be described.

[0072] Modified layered double metal hydroxide: sodium stearate and layered double metal hydroxide (neutral pH value) are added to the reaction kettle according to the proportioning of (3-5): 100 parts by weight, at 75- Stir in the temperature range of 85°C for 1 hour, and ultrasonically disperse once at intervals of 10-15 minutes, each time for 3-5 minutes.

[0073] Effect of ratio on activation index:

[0074] Addition amount of sodium stearate 1% 3% 5% 7% 10% Activation index 0.23 0.89 0.985 0.987 0.988

[0075] Applicant finds in research, initially along with the increase of sodium stearate, activation index rises sharply, but when sodium stearate increases to about 5% of layered double metal hydroxide content, its activation index tends to When it is stable (close to 1), it continues to increase at this time, and the activati...

Embodiment 3

[0080] Preparation of modified silica: Add a certain amount of propyltrimethylsilane (KH560) into the hydrolyzate and hydrolyze it for 30±5min at a temperature of 70-75°C to obtain a hydrolysis reactant; add a certain amount of nano-silica (10-30nm) Add a certain amount of absolute ethanol, ultrasonically disperse for 10-15min to obtain a dispersion; heat the hydrolyzed reactant and dispersion to 80-85°C in the reactor, stir at constant temperature for 4H, then cool to room temperature, Obtaining the cooling liquid; centrifuging the cooling liquid and drying to constant humidity to obtain modified nano silicon dioxide;

[0081] The hydrolyzate is prepared from ethanol with a volume fraction greater than 75% and hydrochloric acid with a concentration of 0.1mol / L at a volume ratio of 1:1;

[0082] The addition ratio of each material is as follows:

[0083] Propyltrimethylsilane Nano silica Hydrolyzate Absolute ethanol 12-18g 100g 1000mL 500ml

[0084...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com