Halogen-free phosphorus-containing flame retardant, flame-retardant transparent polycarbonate material, and preparation and application of halogen-free phosphorus-containing flame retardant and flame-retardant transparent polycarbonate material

A technology of polycarbonate and flame retardant, which is applied in the field of flame retardants and can solve the problem of large amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

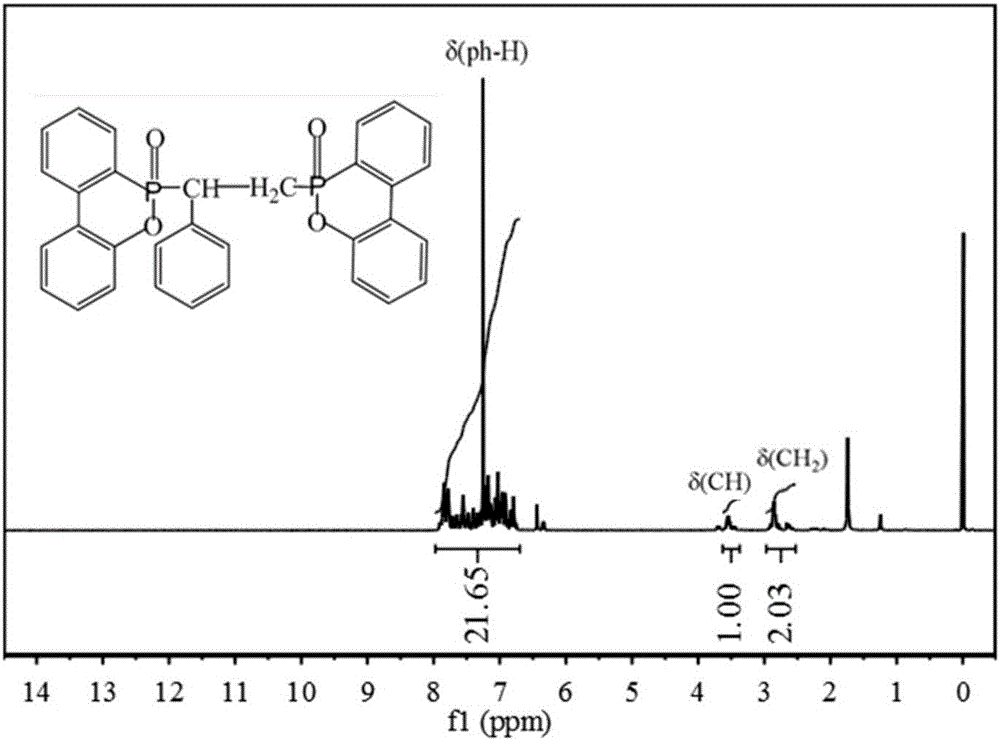

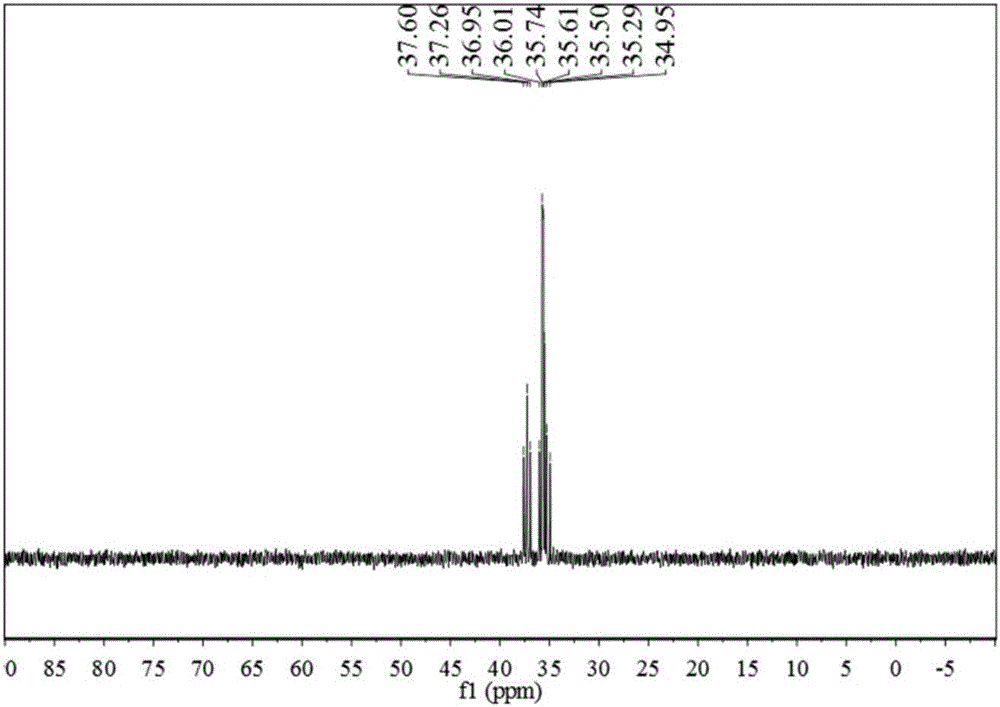

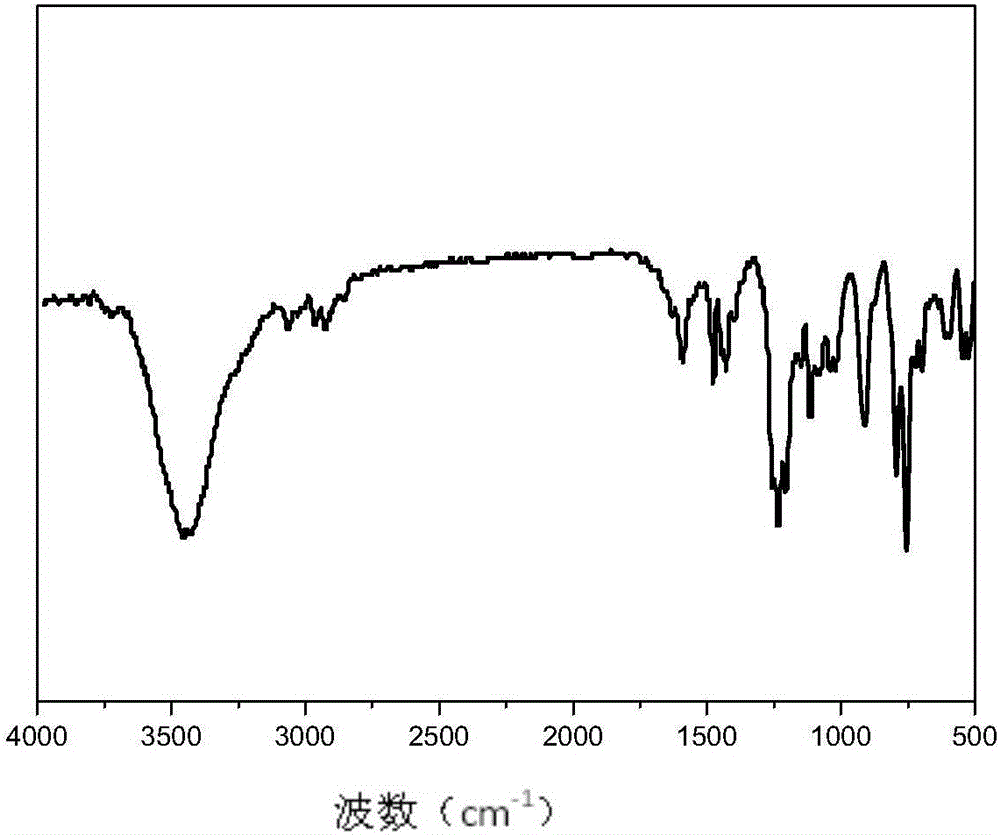

Method used

Image

Examples

Embodiment 1

[0082] (1) The commercially available PC resin was dried at a temperature of 120° C. for 4 h.

[0083] (2) Under reflux at a temperature of 60°C, dissolve the DOPO compound represented by the above structural formula (I) in which R1 is phenylethyl in an ethanol solvent, wherein the mass ratio of the DOPO compound to the solvent is 1:10, and then The flame retardant composition is obtained by adding nano silicon dioxide and blending under the condition of supercritical carbon dioxide at 20° C. and 20 MPa. Wherein, the mass ratio of DOPO compound to nano silicon dioxide is 4:1, the supercritical carbon dioxide pressure is 20MPa, and the time is 4h.

[0084] (3) Weigh the PC resin / flame retardant composition obtained in step (1) and mix it uniformly according to the mass ratio of 90 / 10 to form 1Kg of raw materials.

[0085] (4) Add the raw materials after step (3) into a twin-screw extruder for melt blending and extrusion; wherein the twin-screw extruder has 5 sections of temper...

Embodiment 2

[0092] (1) The commercially available PC resin was dried at a temperature of 140° C. for 2 h.

[0093](2) At a temperature of 60°C, dissolve the DOPO compound represented by the above structural formula (I) wherein R1 is naphthyl ethyl in a propanol solvent, wherein the mass ratio of the DOPO compound to the solvent is (1:10) , and then adding nano-silica and blending with nano-silica at a temperature of 60° C., heating to a temperature of 90° C. and evaporating the solvent to obtain a flame retardant composition. Wherein, the mass ratio of DOPO compound to nano silicon dioxide is 3:1, and the time is 5 hours.

[0094] (3) Weigh the PC resin / flame retardant composition obtained in step (1) and mix it uniformly according to the mass ratio of 85 / 15 to form 1Kg of raw materials.

[0095] (4) Add the raw materials after step (3) into a twin-screw extruder for melt blending and extrusion; wherein the twin-screw extruder has 5 sections of temperature control zones, wherein the temp...

Embodiment 3

[0102] (1) The commercially available PC resin was dried at a temperature of 130° C. for 6 h.

[0103] (2) At a temperature of 60°C, dissolve the DOPO compound shown by the above structural formula (I) wherein R1 is naphthyl ethyl in an acetone solvent, wherein the mass ratio of the DOPO compound to the solvent is 1:8, and then add The nano-silica sol was blended with the nano-silica sol at a temperature of 25° C., and then heated to a temperature of 50° C. to evaporate the solvent to obtain a flame retardant composition. Wherein, the mass ratio of the DOPO compound to the silica sol is 5:1, and the time is 5 hours.

[0104] (3) Weigh the PC resin / flame retardant composition obtained in step (1) and mix it uniformly according to the mass ratio of 95 / 5 to form 1Kg of raw materials.

[0105] (4) Add the raw materials after step (3) into a twin-screw extruder for melt blending and extrusion; wherein the twin-screw extruder has 5 sections of temperature control zones, wherein the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com