Halogen-free flame-retardation nylon 6 montmorillonite nanocomposite and preparation method thereof

A nano-composite material, flame-retardant nylon technology, applied in the field of nylon 6 composite materials, can solve the problems of large amount of flame retardant, poor flame retardant effect, burning and dripping, etc., and achieve less amount of flame retardant and flame retardant efficiency. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

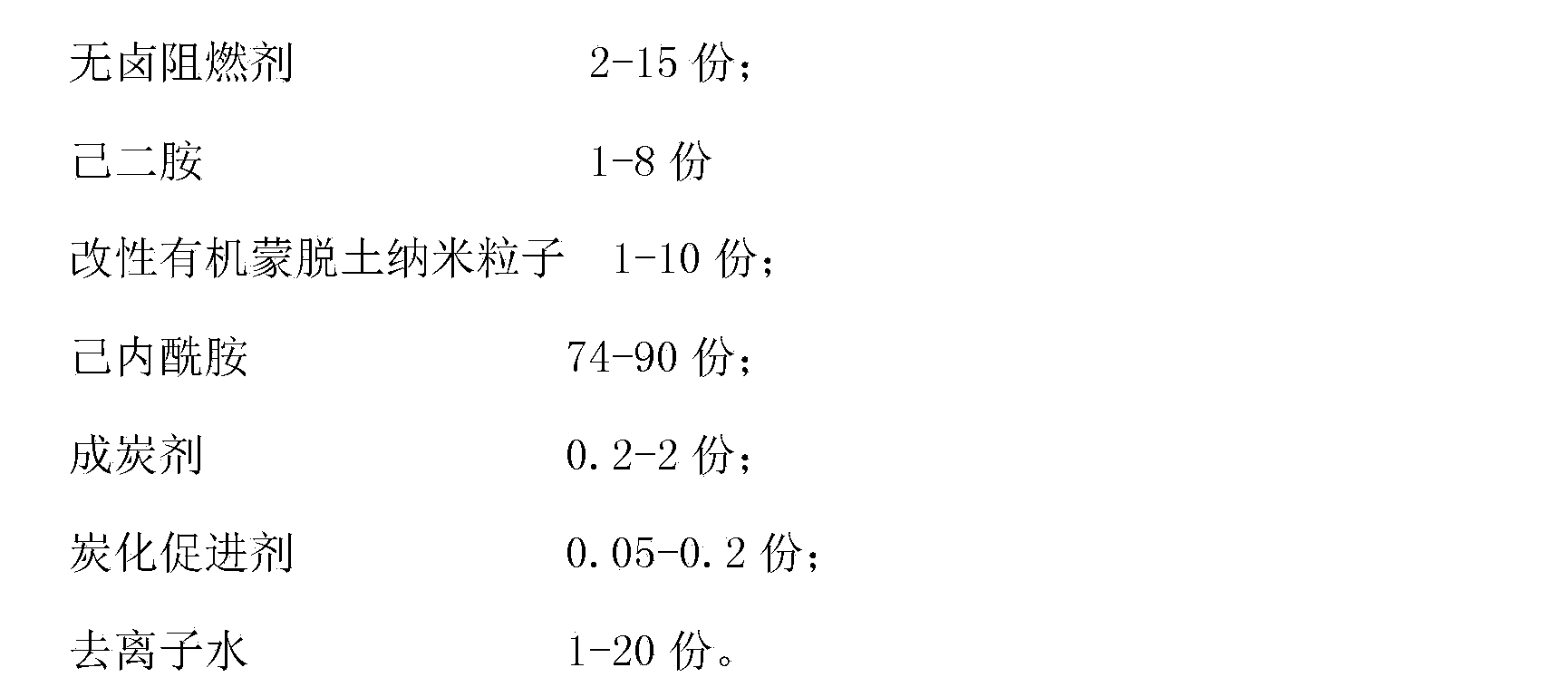

[0027] Step 1, preparation of modified organic montmorillonite nanoparticles

[0028] Add 5 parts of organic montmorillonite nanoparticles to 90 parts of water and mechanically stir to form a stable suspension, add 5 parts of long-chain alkyl bromide tetradecyltriphenylphosphine bromide to carry out cation exchange reaction, and heat to 80°C in a water bath React for 5h, suction filter after the exchange is completed, and wash the precipitate with distilled water until there is no Br in the filtrate - ion. The obtained organic montmorillonite was dried and passed through a 200-mesh sieve. The reaction equation is:

[0029]

[0030] Step 2, preparation of flame retardant salt

[0031] The preparation method of the halogen-free flame retardant is as follows: 10 parts by weight of 2-carboxyethylphenylphosphinic acid and 5 parts by weight (removed) of hexamethylenediamine are dissolved in N,N-dimethylformamide, and the constant temperature water bath Keep the water temperat...

Embodiment 2)

[0036] Step 1, preparation of modified organic montmorillonite nanoparticles

[0037] Add 5 parts of organic montmorillonite nanoparticles to 90 parts of water and mechanically stir to form a stable suspension, add 5 parts of long-chain alkyl bromide hexadecyltributylphosphine bromide for cation exchange reaction, and heat to 80°C in a water bath React for 5h, suction filter after the exchange is completed, and wash the precipitate with distilled water until there is no Br in the filtrate - ion. The obtained organic montmorillonite was dried and passed through a 200-mesh sieve.

[0038] Step 2, preparation of flame retardant salt

[0039] The preparation method of the halogen-free flame retardant is as follows: 4 parts by weight of bis(p-carboxyphenyl)phenylphosphine oxide and 2 parts by weight of hexamethylenediamine are dissolved in N,N-dimethylformamide, and the constant temperature water bath Keep the water temperature at 55°C and react for 3-5h, then cool, filter, and wa...

Embodiment 3)

[0043] Step 1, preparation of organic montmorillonite

[0044] Add 5 parts of montmorillonite to 90 parts of water and mechanically stir to form a stable suspension, add 5 parts of long-chain alkyl bromide hexadecyltriphenylphosphine bromide to carry out cation exchange reaction, heat the water bath to 80 ° C for 5 hours, After the exchange is completed, filter with suction, and wash the precipitate with distilled water until there is no Br in the filtrate - ion. The obtained organic montmorillonite was dried and passed through a 200-mesh sieve.

[0045] Step 2, preparation of flame retardant salt

[0046] The preparation method of the halogen-free flame retardant is as follows: 15 parts by weight of 2-carboxyethylphenylphosphinic acid and 5 parts by weight of hexamethylenediamine are dissolved in N,N-dimethylformamide, and the water temperature is kept in a constant temperature water bath. React at 55°C for 3-5h, then cool, filter, and wash with absolute ethanol.

[0047]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com