Anti-aging flame-retardant PVC material and preparation method and application of anti-aging flame-retardant PVC material in wire or cable

A PVC material, anti-aging technology, used in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of poor UV aging resistance, heavy smoke, and inconsistent with the layout of green economic development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

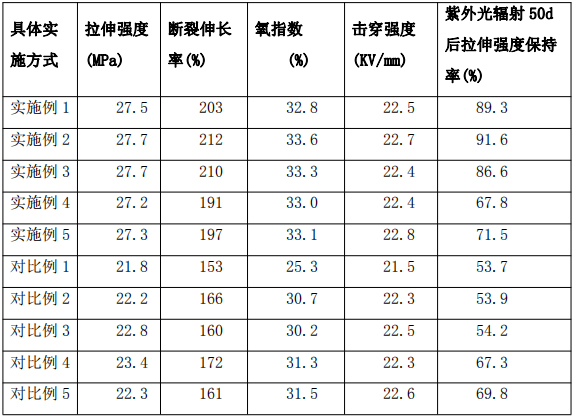

Examples

Embodiment 1

[0034] Put 6 parts of acid lignin, 0.5 parts of zinc stannate, 1 part of zinc stearate, dimer acid diisocyanate (10% of acid lignin) and ALLCHEM360 (0.8% of dimer acid diisocyanate) in a high mixer Mix for 15 minutes, then ball mill at high speed in a ball mill for 5 hours to obtain a mixture with a D50 of 5.5 microns; then mix the above mixture with 100 parts of PVC, 6 parts of calcium zinc stabilizer, 35 parts of octyl phthalate, and 55 parts of calcium carbonate , 2 parts of antioxidant, added to a high mixer and mixed to obtain a precursor; the precursor was melted, blended and extruded by a twin-screw extruder, and granulated to obtain a green, environmentally friendly, anti-aging, flame-retardant PVC wire and cable Material. The first zone of the twin-screw extruder is 110°C, the second zone is 130°C, the third zone is 150°C, the fourth zone is 160°C, the fifth zone is 170°C, the sixth zone is 180°C, the head is 175°C, and the screw speed is 120rpm.

Embodiment 2

[0036]Put 10 parts of acid lignin, 0.8 parts of zinc stannate, 1.5 parts of zinc stearate, dimer acid diisocyanate (12% of acid lignin) and ALLCHEM360 (0.8% of dimer acid diisocyanate) in a high mixer Mix for 20 minutes, then ball mill at high speed in a ball mill for 6 hours to obtain a mixture with a D50 of 4.6 microns; then mix the above mixture with 100 parts of PVC, 8 parts of calcium zinc stabilizer, 40 parts of octyl phthalate, 60 parts of calcium carbonate , 2 parts of antioxidant, added to a high mixer and mixed to obtain a precursor; the precursor was melted, blended and extruded by a twin-screw extruder, and granulated to obtain a green, environmentally friendly, anti-aging, flame-retardant PVC wire and cable Material. The first zone of the twin-screw extruder is 120°C, the second zone is 135°C, the third zone is 150°C, the fourth zone is 165°C, the fifth zone is 170°C, the sixth zone is 180°C, the head is 175°C, and the screw speed is 150rpm.

Embodiment 3

[0038] Put 5 parts of acid lignin, 1 part of zinc stannate, 1.5 parts of zinc stearate, dimer acid diisocyanate (20% of acid lignin) and ALLCHEM360 (1% of dimer acid diisocyanate) in a high mixer Mix for 30 minutes, and then ball mill at high speed in a ball mill for 8 hours to obtain a mixture with a D50 of 3.2 microns; then mix the above mixture with 100 parts of PVC, 8 parts of calcium zinc stabilizer, 30 parts of octyl phthalate, and 70 parts of calcium carbonate , 2 parts of antioxidant, added to a high mixer and mixed to obtain a precursor; the precursor was melted, blended and extruded by a twin-screw extruder, and granulated to obtain a green, environmentally friendly, anti-aging, flame-retardant PVC wire and cable Material. The first zone of the twin-screw extruder is 115°C, the second zone is 135°C, the third zone is 150°C, the fourth zone is 165°C, the fifth zone is 175°C, the sixth zone is 180°C, the head is 175°C, and the screw speed is 200rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com