Room-temperature vulcanized antiflaming single-component dealcoholization-type silicone rubber sealant and preparation method thereof

A room temperature vulcanization, silicone rubber technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of mechanical properties decline, affecting the electrical properties of the sealant, and high hardness of the sealant, and achieve the effect of reducing the amount of addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

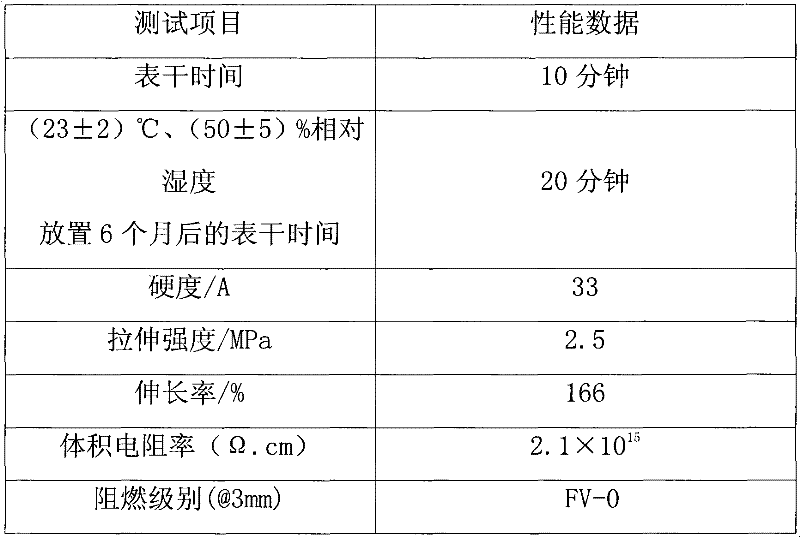

Image

Examples

Embodiment 1

[0029] The silicone rubber sealant of the present invention includes (A)-(J) components, and the mass parts of each component are as follows:

[0030] (A) 50 parts of α, ω-divinyl polydimethylsiloxane

[0031] (B) 7.5 parts of polydimethylsiloxane whose end group is hydrogen

[0032] (C) 1.5 parts of vinyltrimethoxysilane

[0033] (D) 2 parts of platinum catalyst

[0034] (E) 4 parts of fumed white carbon black

[0035] (F) 20 parts of inorganic flame retardant aluminum hydroxide

[0036] (G) 6 parts of cross-linking agent

[0037] (H) 4 parts of titanate catalyst

[0038] (1) 3 parts of silane coupling agent

[0039] (J) Hydroxyl and moisture scavenger 2 parts

[0040] Wherein the (A) component is α, ω-divinylpolydimethylsiloxane with a viscosity of 10000cps at 25°C; the (B) component is a hydrogen-terminated silicone oil with a molecular weight of 1000; the ( C) component is vinyltrimethoxysilane; (D) component is platinum catalyst; (E) component is fumed white carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com