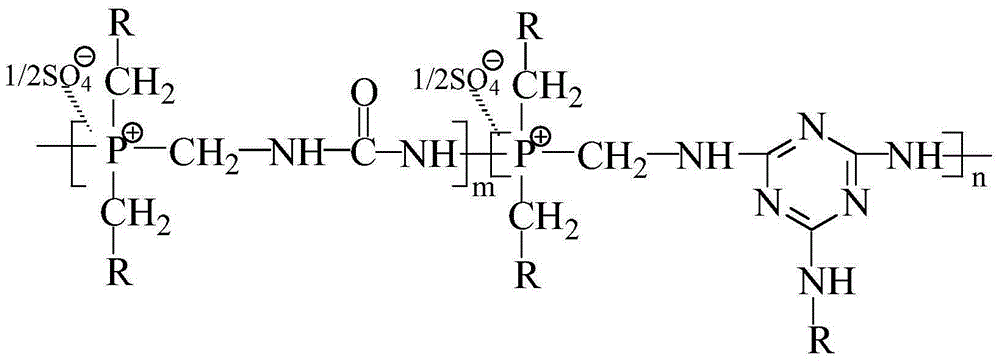

Cross-linked type insoluble halogen-free flame retardant and preparation method and application thereof

A flame retardant, cross-linked technology, used in the field of halogen-free flame retardants, cross-linked insoluble halogen-free flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

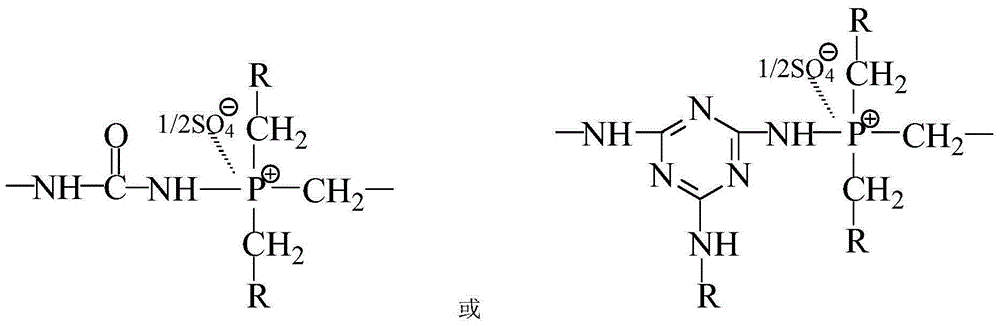

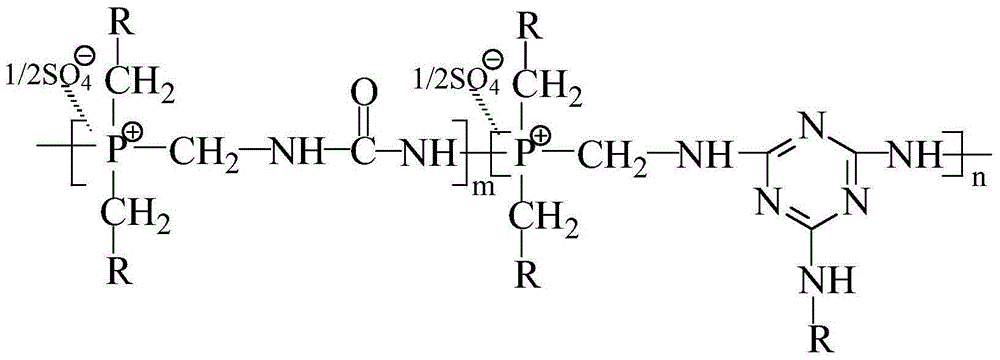

Method used

Image

Examples

Embodiment 1

[0022] Add 216g (0.4mol) 75% solid content tetrakis hydroxymethyl phosphorus sulfate aqueous solution, 78g (1.3mol) urea, 25.2g (0.2mol) melamine, 2.2g hexamethylenetetramine in the bottle mouth detachable flask Mix with 110g of water, stir and heat up to 60°C. After reacting for 60 minutes, add 4.4g of aminopropyl triethoxysiloxane. After heating up to 95°C for 10 minutes, the viscosity of the reactant gradually increases, and gradually fades from milky white. After continuing to stir and react for 2 minutes, a viscous transparent substance was formed, and the viscosity increased rapidly to form a transparent brittle gel. Take out the gel, dry it in a blast drying oven at 120°C for 4 hours, take out the dried white lump, grind it in a grinder to a size above 300 mesh, and obtain a cross-linked insoluble halogen-free flame retardant.

Embodiment 2

[0024] Add 216g (0.4mol) 75% solid content tetrakis hydroxymethyl phosphorus sulfate aqueous solution, 60g (1mol) urea, 37.8g (0.45mol) dicyandiamide, 12.6g (0.1mol) melamine in the detachable flask of bottle mouth , 4g hexamethylenetetramine and 160g water, stir and heat up to 70°C, react for 40min, add 6g of aminopropyltrimethoxysiloxane, heat up to 95°C and react for 10min, the viscosity of the reactant gradually increases, From milky white to light gradually, after continuing to stir and react for 2 minutes, a viscous transparent substance was formed, and the viscosity increased rapidly to form a transparent brittle gel. Take out the gel, dry it in a blast drying oven at 120°C for 4 hours, take out the dried white lump, grind it in a grinder to a size above 300 mesh, and obtain a cross-linked insoluble halogen-free flame retardant.

Embodiment 3

[0026] Add 216g of 75% solid content tetrakis hydroxymethyl phosphorus sulfate aqueous solution, 60g of urea, 50.4g of melamine, 6.48g of hexamethylenetetramine and 216g of water into a flask with a detachable neck, stir and raise the temperature to 70°C, and react for 60min Finally, add 10.8g of aminopropyl trimethoxysiloxane, heat up to 95°C and react for 15 minutes, the viscosity of the reactant gradually increases, and gradually fades from milky white. After continuing to stir and react for 2 minutes, a viscous transparent substance is formed, and the viscosity increases rapidly. Large transparent brittle gels are formed. Take out the gel, dry it in a blast drying oven at 100°C for 6 hours, take out the dried white lump, grind it in a grinder to a size above 300 mesh, and obtain a cross-linked insoluble halogen-free flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com