Degradable plastic

A technology for degrading plastics and plasticizers, applied in the field of degradable plastics, can solve the problems of biodegradable plastics that are difficult to degrade, white pollution damages the environment, and cannot be degraded, and achieves the effects of easy production, complete degradation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

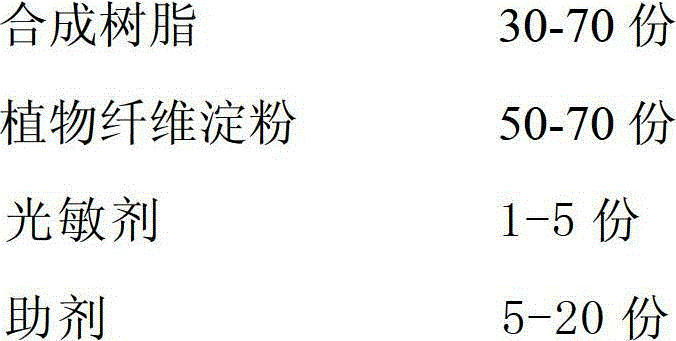

[0019] A degradable plastic consisting of the following components by weight:

[0020]

[0021] Among the additives:

[0022] Tributyl citrate 2kg

[0024] Triphenyl phosphite 1kg

Embodiment 2

[0026] A degradable plastic consisting of the following components by weight:

[0027]

[0028] Among the additives:

[0029] Tributyl acetate 8kg

[0031] Triphenyl phosphite 4kg

Embodiment 3

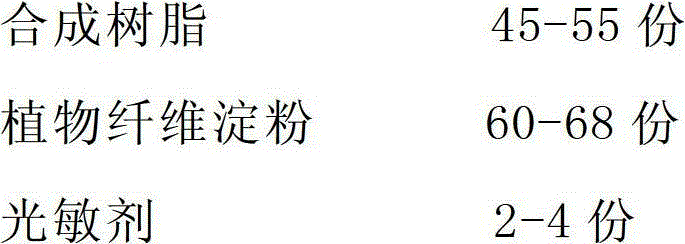

[0033] A degradable plastic consisting of the following components by weight:

[0034]

[0035]

[0036] Among the additives:

[0037] Mineral oil 4kg

[0039] Triphenyl phosphite 2kg

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com