Synthetic method of polyethylene glycol terephthalate from biomass glycol

A technology of polyethylene terephthalate and biomass ethylene glycol is applied in the field of polyester synthesis to achieve the effects of saving energy, reducing dependence and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

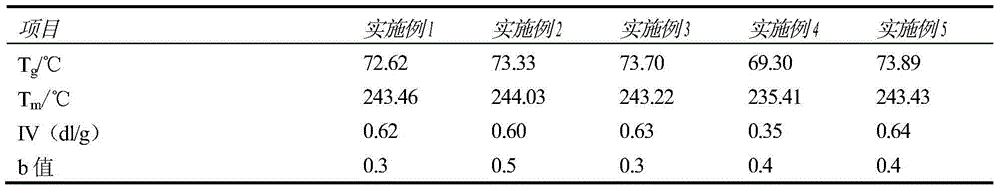

Embodiment 1

[0019] Biomass ethylene glycol is used to react with terephthalic acid, and the molar ratio of these two raw materials is 1.3. The fusel alcohols in biomass ethylene glycol are ethanol, 1,2-propanediol, 1,2-butanediol, 1,2-pentanediol, 1,2-hexanediol, and the mass content of several alcohols is 0.01 %, 0.02%, 0.03%, 0.01%, 0.01%.

[0020] PET preparation steps:

[0021] (1) Put 90g of ethylene glycol and 180g of terephthalic acid into the reaction kettle, heat up to 120°C and stir for 20 minutes;

[0022] (2) Slowly add the composite catalyst lithium acetate and germanium oxide. The mass of the two is added in a ratio of 1:2. The amount added is 300ppm equivalent to the amount of terephthalic acid. The temperature of the slurry was raised to 250°C to start the esterification reaction. During the esterification reaction, maintain a fixed pressure (0.3-0.4MPa) until the first drop of water flows out, and then slowly release the pressure until the water output reaches more tha...

Embodiment 2 and 3

[0026] Polyester is synthesized with biomass ethylene glycol. The types of fusel alcohols in biomass ethylene glycol are the same as in Example 1, but the fusel alcohol content is different. The mass contents of 2 kinds of fusel alcohols in embodiment are respectively 0.01%, 0.1%, 0.05%, 0.03%, 0.01%, and the mass contents of the three kinds of fusel alcohols in the examples are 0.1%, 0.05%, 0.2%, 0.05%, and 0.1%, respectively.

[0027] The process of synthesizing polyester from terephthalic acid and biomass ethylene glycol is the same as in Example 1.

Embodiment 4

[0029] Polyester is synthesized with biomass ethylene glycol, and the type of fusel alcohol in biomass ethylene glycol is the same as in Example 1, and the content is also the same, but the catalyst used is a single-component catalyst germanium oxide, and the addition is equivalent to the amount of terephthalic acid 300ppm, other conditions in the synthetic process of polyester are the same with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com