Stress-cracking-resistant polycarbonate composite material and preparation method thereof

A technology of stress cracking resistance and polycarbonate, which is applied in the field of polycarbonate composite modified materials and its preparation, stress cracking resistant polycarbonate composite materials and its preparation, can solve the problems of complex preparation process and high cost of finished products, To achieve the effect of improving comprehensive performance, good cracking resistance and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

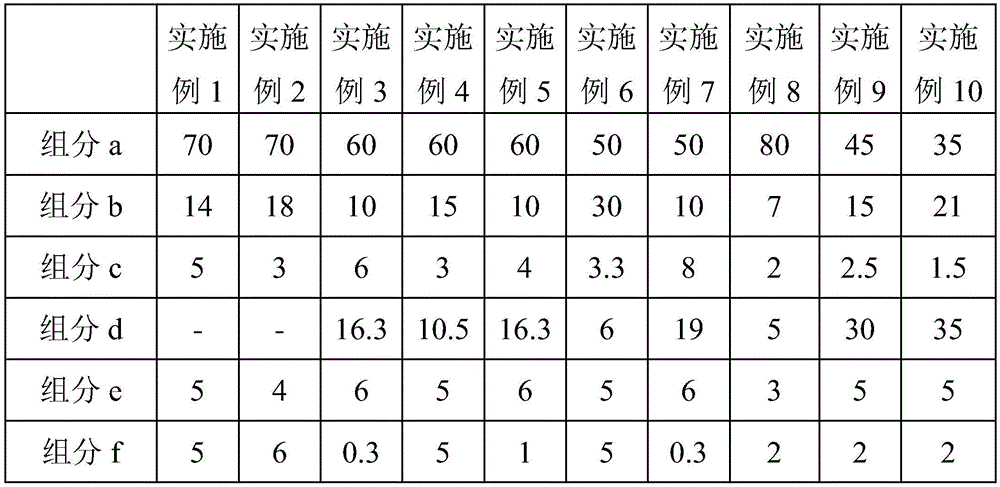

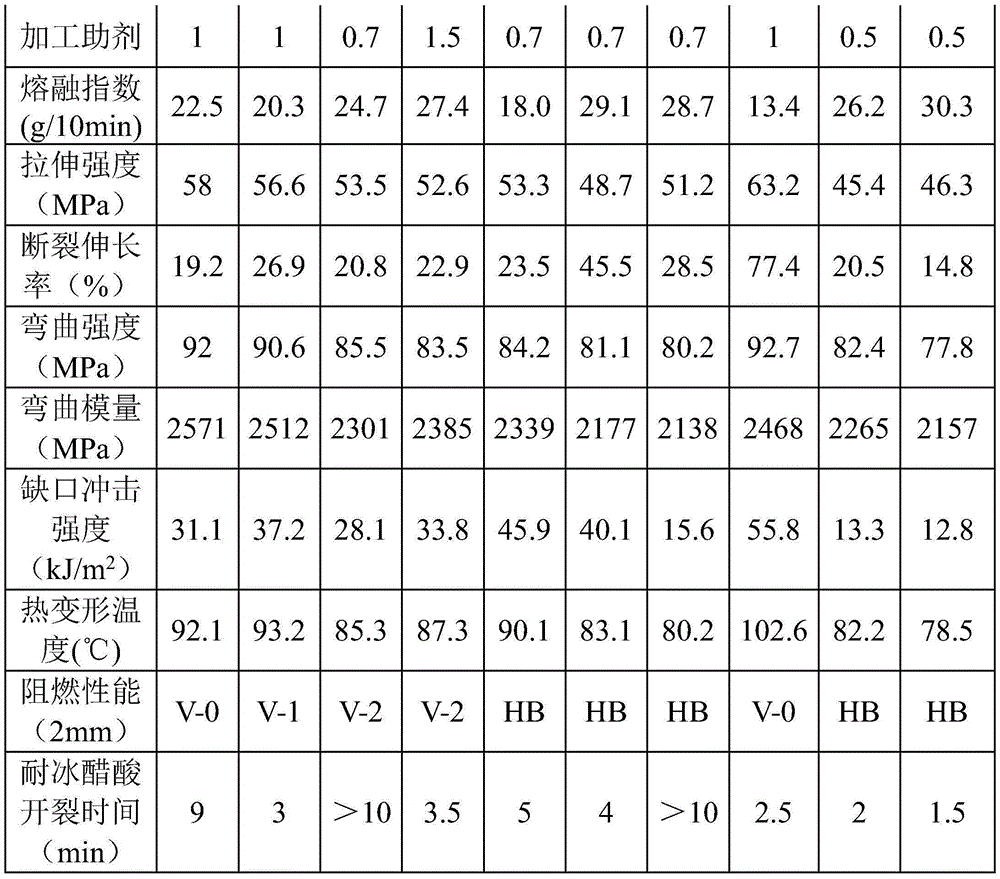

[0025] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

[0026] The polycarbonate used in the present invention is at least one of aromatic polycarbonate, aliphatic polycarbonate, aromatic-aliphatic polycarbonate, branched polycarbonate, and siloxane copolycarbonate. The polycarbonate is an aromatic polycarbonate with a viscosity average molecular weight of 13000-40000, preferably an aromatic polycarbonate with a viscosity average molecular weight of 16000-28000.

[0027] The ABS polymer used in the present invention is at least one of the rubber-modified ABS graft polymers prepared by bulk polymerization, emulsion polymerization or bulk-suspension polymerization. The above-mentioned rubber-modified ABS graft polymer is a polymer formed by grafting the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com