Ultrasonic-assisted wood veneer dyeing method

A wood veneer and ultrasonic technology is applied in the field of wood dyeing, which can solve the problems of poor dye penetration and uneven dyeing of wood veneers, and achieve the effects of improving activation energy, good economic and social benefits, promotion prospects, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

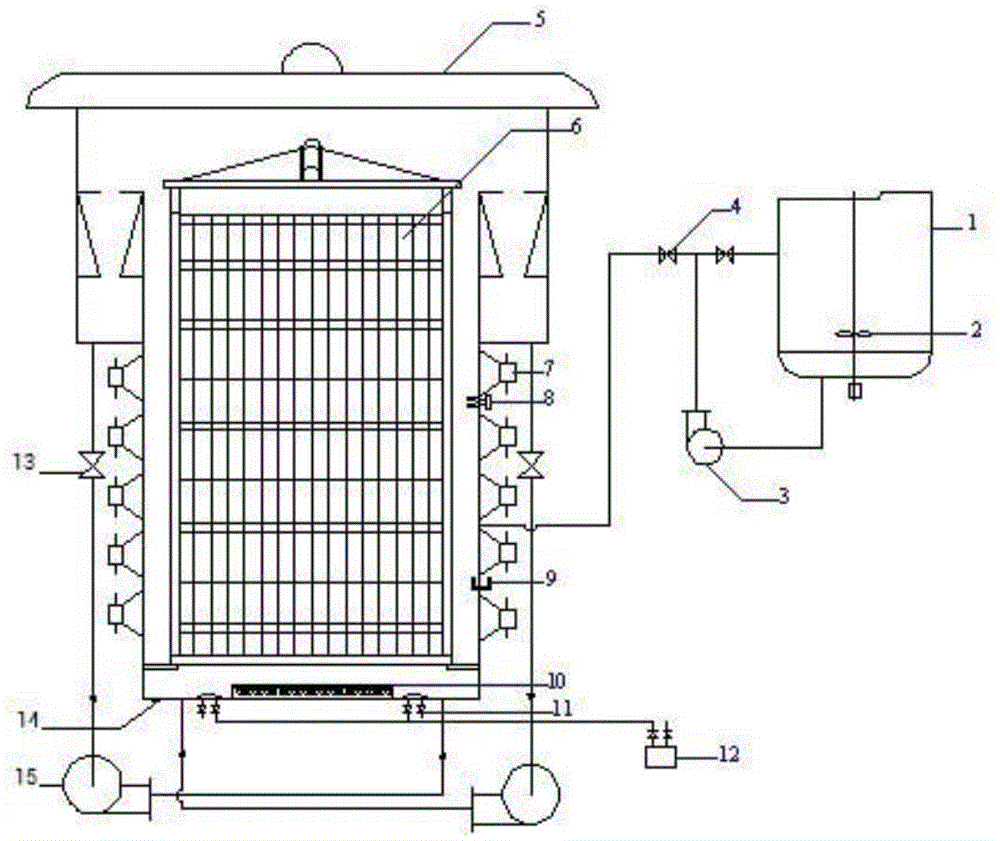

Method used

Image

Examples

Embodiment 1

[0053] Rotate the fast-growing poplar logs into veneers with a thickness of 1.5mm, cut them into veneers with a format of 850mm*560mm, remove defective parts, dry them until the moisture content is less than 8%, polish the surface with 200-grit sandpaper, and put them into a dyed veneer. shelf.

[0054] Prepare acid red GR (C.I.Acid Red 73) dye solution with a dye mass fraction of 0.15% in the batching tank, add 0.15% anhydrous Na 2 SO 4 As a buffer, add 1% dye accelerator NaCl, turn on the agitator to fully dissolve the dye, and slowly add 10% H 2 SO 4 Solution, adjust the pH value of the dye solution to 4.0.

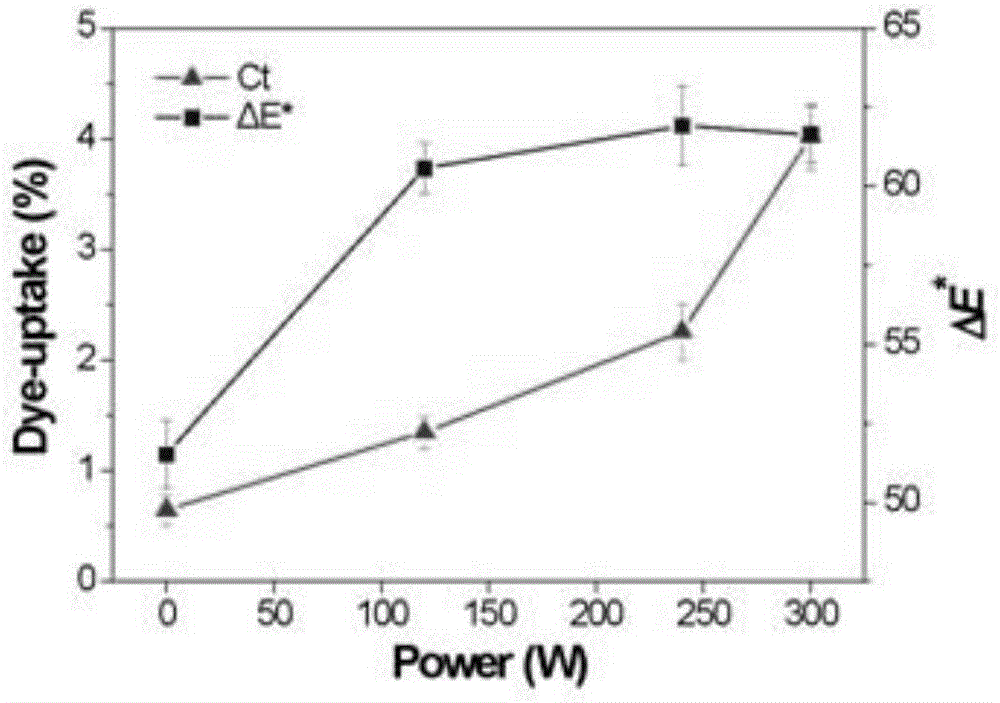

[0055] Pump the dye into the dye vat, turn on the dye solution single circulation system, after the dye solution circulates smoothly, turn on the electric heater, heat the dye solution to 80°C, turn on the ultrasonic transmitter, adjust the ultrasonic power to 0W, 120W, 240W or 300W, Frequency is 20KHz, processing 2h. After reaching the dyeing time, open the dyein...

Embodiment 2

[0057] Cut birch logs into veneers with a thickness of 1.5mm, cut them into veneers with a width of 850mm*560mm, remove defective parts, dry to a moisture content of <8%, polish the surface with 200-grit sandpaper, and put it into a dyeing rack .

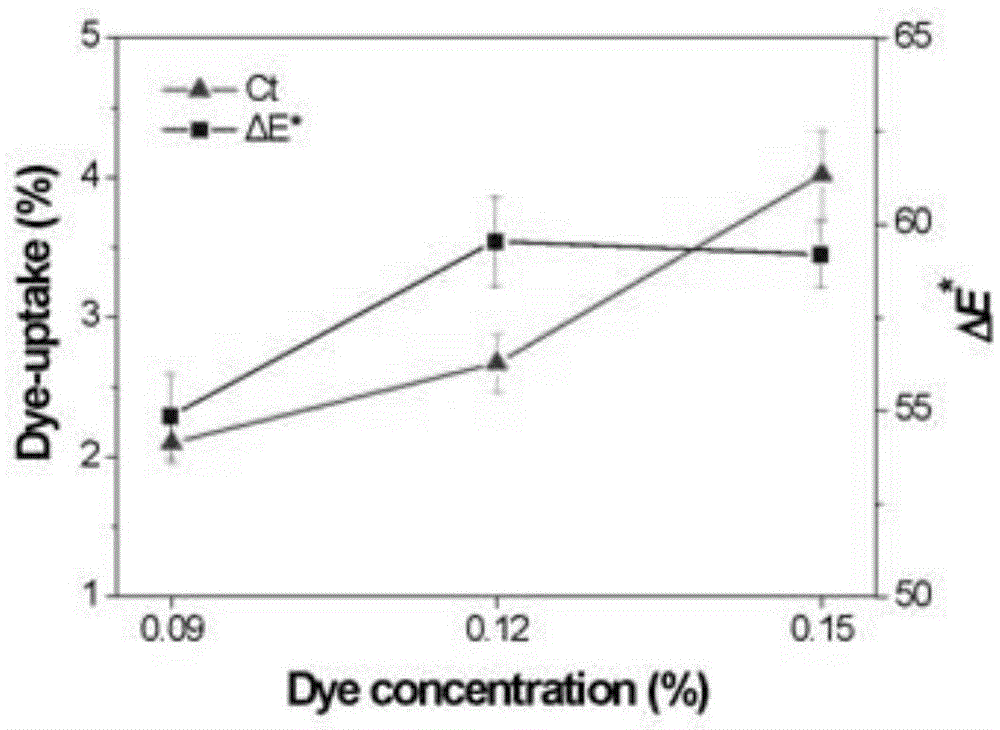

[0058] In the batching tank, the acid red GR (C.I.Acid Red 73) dye solution with a dye mass fraction of 0.09%, 0.12% or 0.15% was prepared respectively, and 0.15% anhydrous Na 2 SO 4 As a buffer, add 1% dye accelerator NaCl, turn on the agitator to fully dissolve the dye, and slowly add 10% H 2 SO 4 Solution, adjust the pH value of the dye solution to 4.0.

[0059] Pump the dye into the dye vat, turn on the double circulation system of the dye liquor, after the dye liquor circulates smoothly, turn on the steam heater, heat the dye liquor to 80°C, turn on the ultrasonic transmitter, adjust the ultrasonic power to 300W, the frequency to 20KHz, and process for 2 hours . When the dyeing time is up, open the cover of the dyeing vat,...

Embodiment 3

[0061] Rotate the sycamore logs into veneers with a thickness of 1.2mm, cut them into veneers with a width of 850mm*560mm, remove defective parts, dry to a moisture content of <8%, polish the surface with 200-grit sandpaper, and put it into a dyeing rack .

[0062] Prepare acid red GR (C.I.Acid Red 73) dye solution with a dye mass fraction of 0.15% in the batching tank, add 0.15% anhydrous Na 2 SO 4 As a buffer, add 1% dye accelerator NaCl, turn on the agitator to fully dissolve the dye, and slowly add 10% H 2 SO 4 Solution, adjust the pH value of the dye solution to 4.0.

[0063] Pump the dye into the dye vat, turn on the dye solution single circulation system, after the dye solution circulates smoothly, turn on the electric heater, heat the dye solution to 80°C, turn on the ultrasonic transmitter, adjust the ultrasonic power to 300W, the frequency to 20KHz, and process for 1h , 2h, 3h, 4h or 5h. When the dyeing time is up, open the cover of the dyeing vat, hang out the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com