Water-saving and energy-saving polyester dyeing method

A dyeing method and polyester technology, which can be used in dyeing, textile and paper making, etc., can solve the problems of troublesome solvent recovery and high cost, and achieve the effect of less water consumption, broad application prospects and less environmental impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A, the preparation of deep eutectic solvent: after choline chloride, glycerol, benzyl alcohol are mixed in molar ratio 1: 1: 1, heated and stirred in water makes deep eutectic solvent;

[0019] B. Preparation of dyeing solution: disperse dye, DES and water according to the volume ratio, liquor ratio, and then stir evenly to prepare the dyeing solution;

[0020] C. Dyeing: add pre-treated polyester to the dyeing solution, then raise the temperature to 98-100°C at a rate of 1.5-2°C / min, and keep it warm for 40-60 minutes for dyeing;

[0021] D. Post-dyeing treatment: wash the dyed polyester with 60°C hot water first, then wash with cold water, dehydrate and then dry.

[0022] After mixing choline chloride, glycerin, and benzyl alcohol in a molar ratio of 1:1:1, heat and stir in a water bath at 40°C until a transparent liquid is formed to obtain a deep eutectic solvent (DES). Disperse dyes 1 to 3 % (owf), disperse dyes are low-temperature or medium-temperature disperse dy...

Embodiment 1

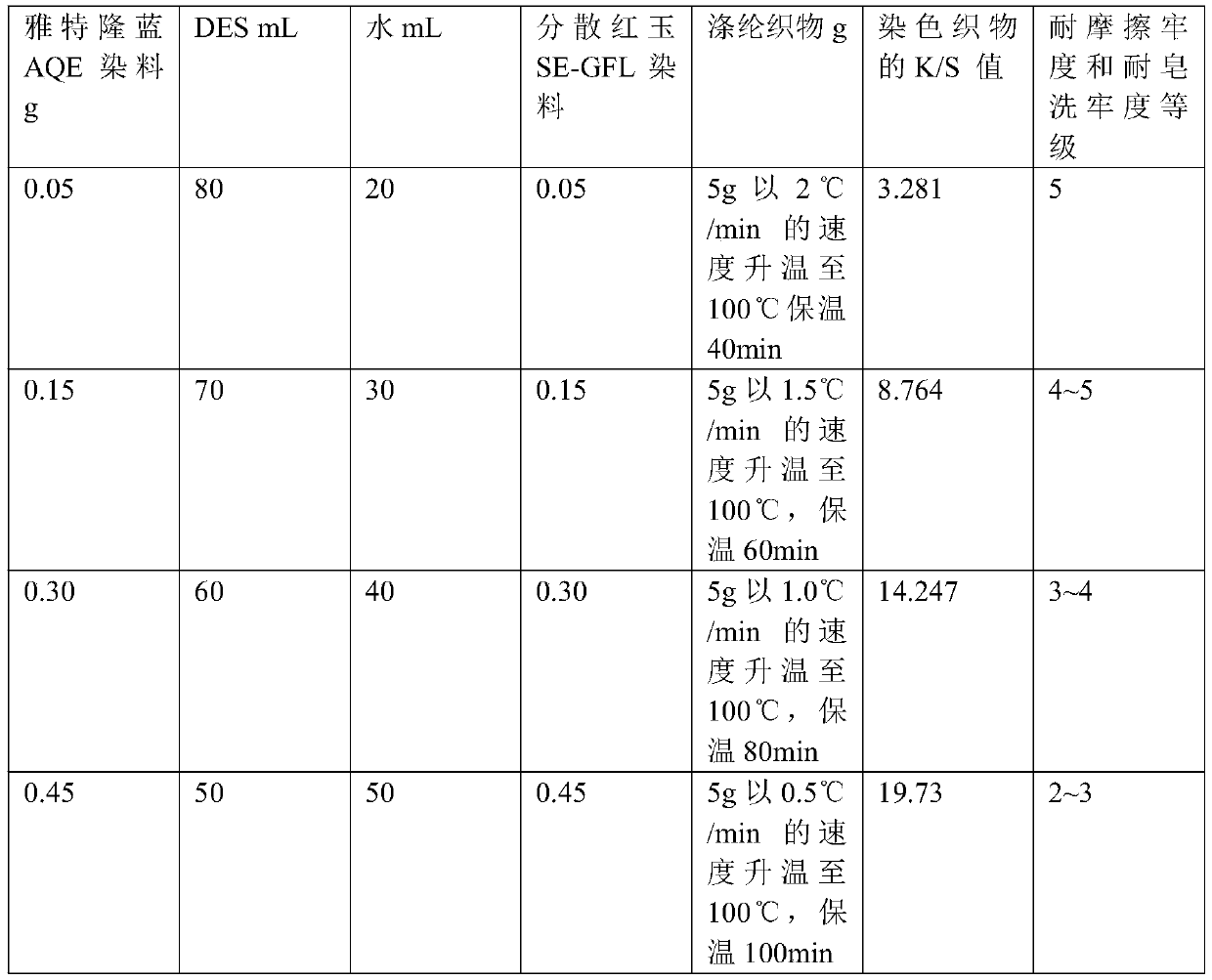

[0024] Embodiment 1: a kind of dyeing method of blue polyester pongee, concrete steps are as follows: A. the preparation of deep eutectic solvent (DES): take by weighing 35g choline chloride, 23g glycerin, 27g benzyl alcohol (each 0.25 mol), after mixing, heat and stir in a water bath at 40°C until a transparent liquid is formed, which is a deep eutectic solvent; Add blue AQE dye to 20mL water to disperse evenly, then add 80mL of DES prepared above, stir evenly at 40°C, and prepare 100mL dye liquor; Speed up to 100°C, keep warm for 40min for dyeing; D. post-dyeing treatment: wash the dyed polyester fabric twice with 60°C hot water, then twice with cold water, dehydrate and then dry. The measured K / S value of the dyed fabric is 3.281, and the rubbing fastness and soaping fastness both reach grade 5.

Embodiment 2

[0025] Embodiment 2: a kind of dyeing method of red polyester pongee, concrete steps are as follows: A. the preparation of deep eutectic solvent (DES): take by weighing 35g choline chloride, 23g glycerol, 27g benzyl alcohol (each 0.25mol ), after mixing, heat and stir in a water bath at 40°C until a transparent liquid is formed to obtain a deep eutectic solvent; B. Preparation of the dyeing solution: weigh 0.15g of disperse ruby SE-GFL according to the dyeing depth of 3% (owf). Add the dye to 30mL water to disperse evenly, then add 70mL of DES prepared above, stir evenly at 40°C, and prepare 100mL dyeing solution; C. Dyeing: Add 5g polyester fabric to the dyeing solution, and then heat up at a speed of 1.5°C / min Dyeing after dyeing: wash the dyed polyester fabric twice with hot water at 60°C, then twice with cold water, dehydrate and dry. The measured K / S value of the dyed fabric is 8.764, the rubbing fastness is grade 5, and the soaping fastness is grade 4-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com