Preparation method of fluorescent yellow polyester-cotton fabric

A fluorescent yellow and disperse fluorescent yellow technology, which is applied in the field of dyeing and finishing, can solve the problems of dyed fabrics such as poor rubbing fastness and hand feel, and long process flow, and achieve the effects of improved hand feel, simple process, and avoiding hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

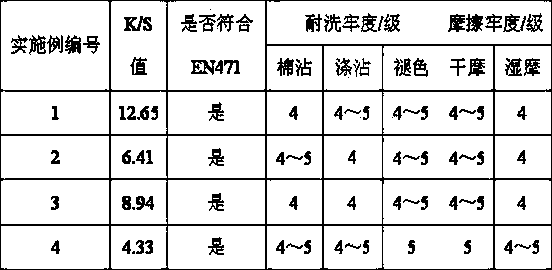

Examples

Embodiment 1

[0015] A preparation method of polyester-cotton fluorescent yellow fabric, the process is as follows: dye the polyester-cotton fabric with disperse fluorescent yellow 10GN and reactive fluorescent yellow FL, first let the disperse fluorescent yellow dye the polyester: add disperse fluorescent yellow 10GN, Reactive Fluorescent Yellow FL, sodium chloride, carrier, pH adjusted to 5, the polyester-cotton fabric is put into the above solution at a bath ratio of 1:20, and the temperature is raised to 90°C at a heating rate of 1°C / min, kept for 30min, and then the above Cool the dyeing solution to 60°C at a cooling rate of 2°C / min, add soda ash to fix the color, and keep it warm for 40 minutes. After the heat preservation is over, wash the dyed fabric with cold water first, then warm water, and then soaping (soaping agent LTS 2g / L, wash at 90°C for 10 minutes), after soaping, wash with cold water and warm water, then dry or air dry the fabric.

[0016] The dye solution prescription ...

Embodiment 2

[0023] A preparation method of polyester-cotton fluorescent yellow fabric, the process is as follows: dye the polyester-cotton fabric with disperse fluorescent yellow 10GN and reactive fluorescent yellow FL, first let the disperse fluorescent yellow dye the polyester: add disperse fluorescent yellow 10GN, Reactive Fluorescent Yellow FL, sodium chloride, carrier, pH adjusted to 4, the polyester-cotton fabric is put into the above solution at a bath ratio of 1:40, and the temperature is raised to 100°C at a heating rate of 2°C / min, kept for 20min, and then the above Cool the dyeing liquor to 50°C at a cooling rate of 3°C / min, then add soda ash to fix the color, keep it warm for 30 minutes, and finally wash, soap, wash, dry or air-dry the dyed fabric.

[0024] The dye solution prescription is as follows:

[0025] Disperse fluorescent yellow 10GN 1% owf

[0026] Reactive fluorescent yellow FL 6% owf

[0027] Sodium chloride 30g / L

[0028] Carrier LEVEGAL? PEW-T 20g / L

[0029] ...

Embodiment 3

[0031] A preparation method of polyester-cotton fluorescent yellow fabric, the process is as follows: dye the polyester-cotton fabric with disperse fluorescent yellow 10GN and reactive fluorescent yellow FL, first let the disperse fluorescent yellow dye the polyester: add disperse fluorescent yellow 10GN, Activate fluorescent yellow FL, sodium chloride, carrier, adjust pH to 6, put polyester-cotton fabric into the above solution at a bath ratio of 1:15, raise the temperature to 85°C at a heating rate of 1.5°C / min, keep it warm for 35min, and then put the above Cool the dyeing liquor to 70°C at a cooling rate of 2.5°C / min, then add soda ash to fix the color, keep it warm for 50 minutes, and finally wash, soap, wash, dry or air-dry the dyed fabric.

[0032] The dye solution prescription is as follows:

[0033] Disperse fluorescent yellow 10GN 1.5% owf

[0034] Reactive fluorescent yellow FL 5% owf

[0035] Sodium chloride 20g / L

[0036] Carrier JYK POW 25g / L

[0037] Soda as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com