Collagen modified poly(3-hydroxybutyrate-3-hydroxyvalerate) and its preparing method and application

A technology of hydroxybutyrate and hydroxyvalerate, applied in the field of collagen modified polymer and its preparation, can solve the problem of unfavorable cell-specific adhesion and specific gene activation, degradable polymer materials do not contain biological information, and lack cell recognition Signal and other issues, to achieve the effect of improving cell adhesion rate, good biocompatibility, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

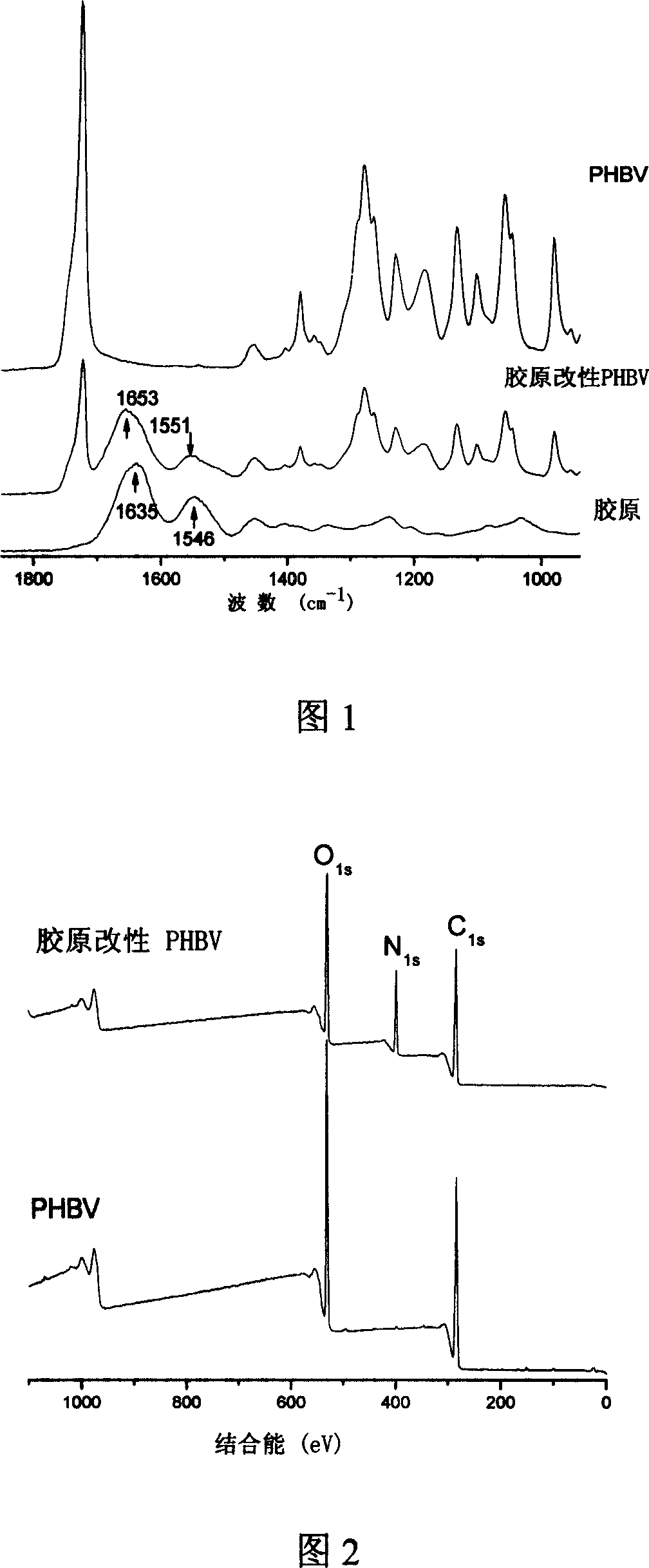

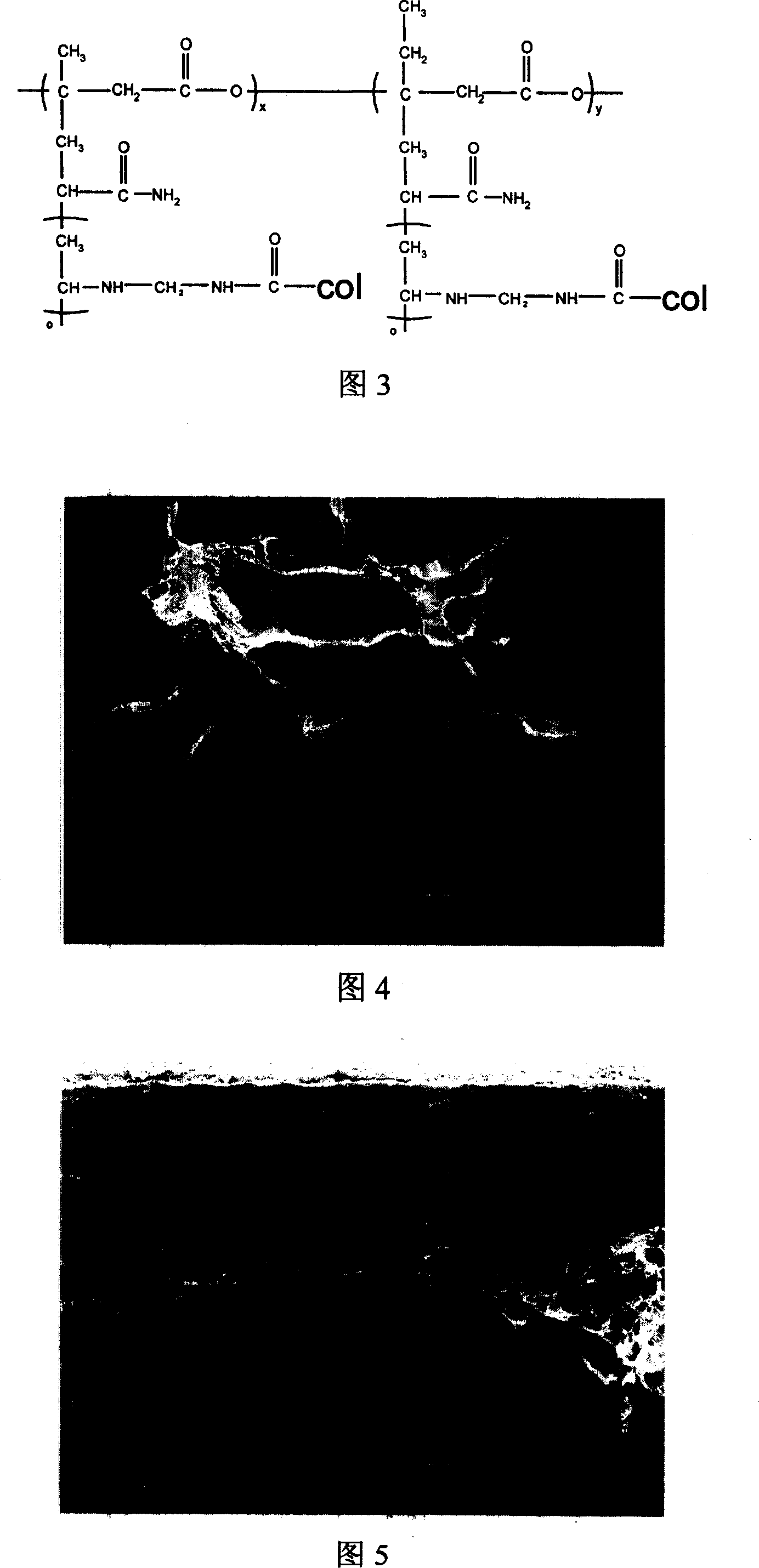

Embodiment 1

[0041] The process of preparing the collagen-modified PHBV material includes the following steps: (1) dissolving 0.06g PHBV in 1ml chloroform solution, and pouring the solution to prepare a PHBV film; (2) soaking the PHBV film prepared in step (1) in a concentration of 0.5% The initiator benzophenone acetone solution 4hr; (3) immerse the PHBV film soaked in the initiator in the aqueous solution of 5% acrylamide, and irradiate with ultraviolet light for 0.5hr; (4) extract with acetone for 48hr, soak in distilled water And dry at 60 DEG C; (5) add 10ml concentration and be the mixed alkaline solution of 5% sodium hydroxide and 6% sodium hypochlorite, wash with water after soaking for 20 minutes; (6) Add 5ml formaldehyde and wash with water after soaking at room temperature; (7) ) adding 10 ml of bovine collagen type I solution with a concentration of 3 mg / ml, standing at room temperature for 6 hours, and then rinsing with water; (8) freeze-drying at -50° C. for 12 hours to obtain...

Embodiment 2

[0048] The process of preparing the collagen-modified PHBV material includes the following steps: (1) dissolving 0.06g PHBV in 0.3ml dichloromethane solution, and pouring the solution to prepare a PHBV film; (2) soaking the PHBV film prepared in step (1) in a concentration of (3) immerse the PHBV membrane soaked in the initiator in an aqueous solution of 30% acrylamide, and irradiate with ultraviolet light for 4hr; (4) extract with acetone for 48hr, soak in distilled water Wash and dry at 60°C; (5) add 30ml concentration of 20% sodium hydroxide and 24% sodium hypochlorite mixed alkali solution, soak for 60 minutes and wash with water; (6) add 30ml formaldehyde for room temperature soak and wash with water; ( 7) Add 30 ml of bovine collagen type I solution with a concentration of 6 mg / ml and place at room temperature for 24 hours, then soak in water; (8) Freeze-dry at -20°C for 24 hours to obtain the modified material of the present invention.

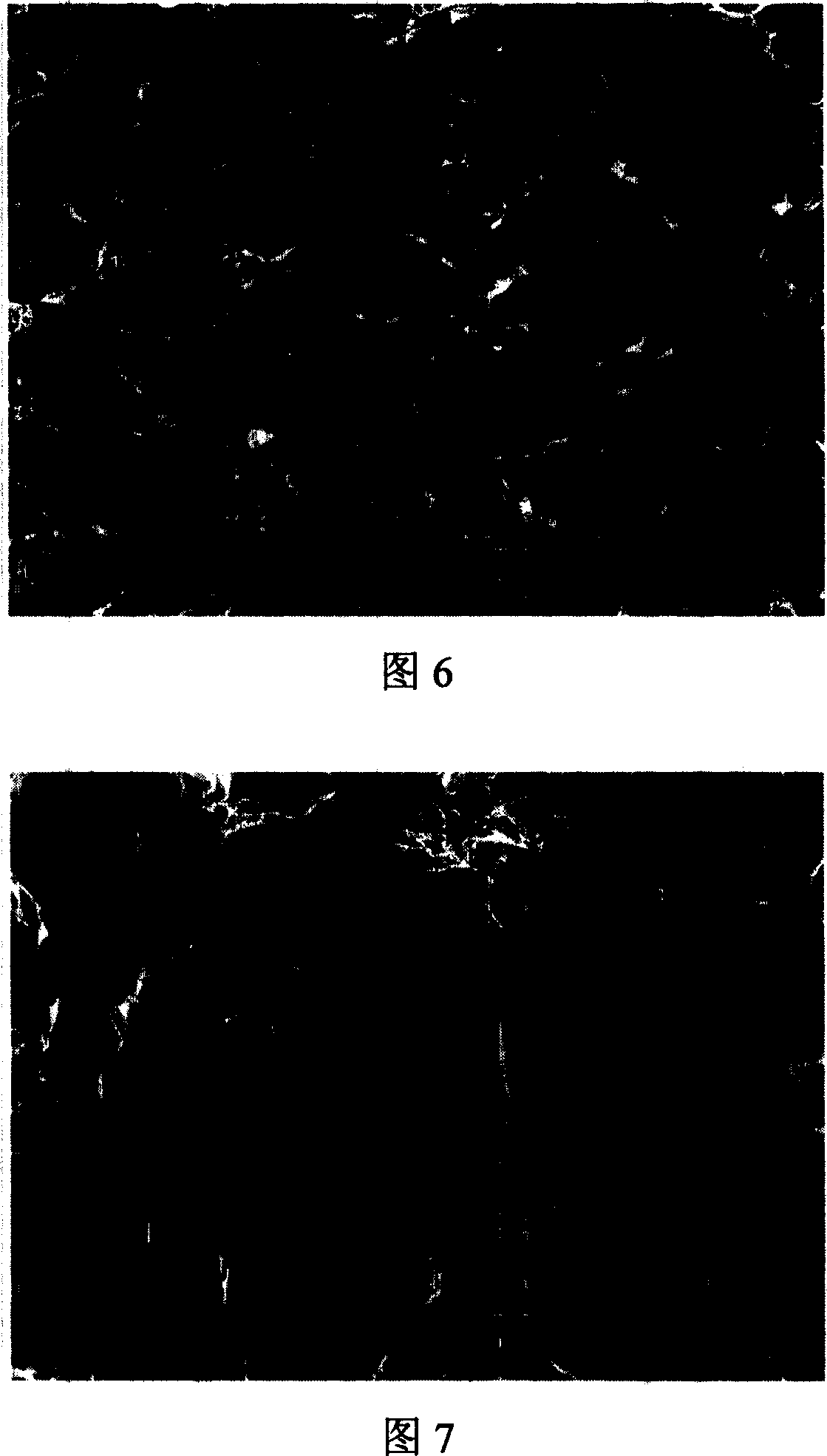

[0049] 6 and 7 are scanning elec...

Embodiment 3

[0055] The process of preparing the collagen-modified PHBV material includes the following steps: (1) dissolving 0.06g PHBV in 0.6ml propylene carbonate solution, and pouring the solution to prepare a PHBV film; (2) soaking the PHBV film prepared in step (1) in The concentration is 1% initiator thioxanthone acetone solution for 8hr; (3) immersing the PHBV membrane soaked in the initiator in the aqueous solution of 10% acrylamide, and irradiating with ultraviolet light for 1hr; (4) extracting with acetone for 48hr, Rinse with distilled water and dry at 60°C; (5) add 15ml of a mixed alkali solution of 10% sodium hydroxide and 12% sodium hypobromite, soak for 30 minutes and wash with water; (6) add 10ml of pentadiene (7) Add 20ml of bovine collagen type I solution with a concentration of 3mg / ml and leave it at room temperature for 12 hours, then wash with water; (8) Freeze-dry at -50°C for 24 hours to obtain the modified material of the present invention.

[0056] The layered str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com