Degradable PHBV (poly hydroxyl butyrate valerate) base 3D (three-dimensional) printing consumable and preparation method thereof

A technology of 3D printing and consumables, applied in the field of 3D printing, can solve the problems of poor mechanical properties and solvent resistance, affecting the precision of printed products, and high crystallinity, and achieve the effect of improving dryness, avoiding precision and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

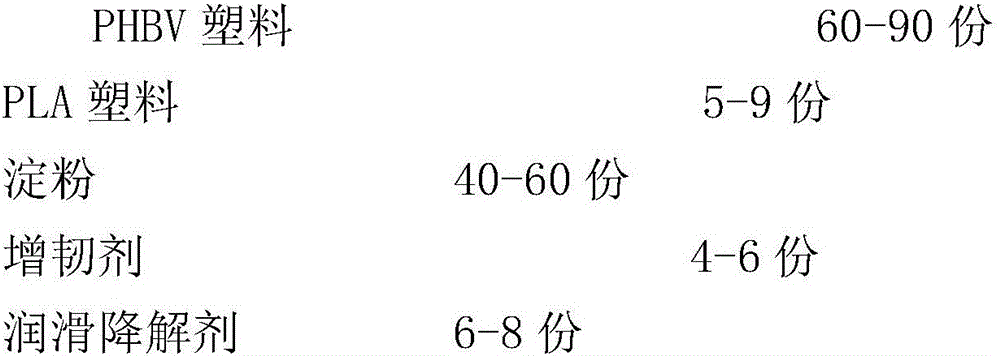

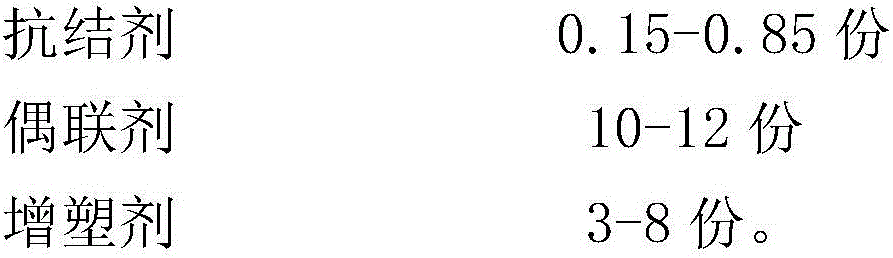

[0037] A PHBV-based degradable 3D printing consumables, comprising the following components by weight:

[0038]

[0039] The weight-average molecular weight of the PHBV plastic is 200,000, and the dispersion coefficient is 1.5.

[0040] Described starch is cornstarch.

[0041] The anticaking agent is sodium aluminosilicate.

[0042] The coupling agent is aluminate.

[0043] The plasticizer is glycerol.

[0044] A preparation method of PHBV-based degradable 3D printing consumables, comprising the steps of:

[0045] (1) Weigh the formula components

[0046] According to the formula of a PHBV-based degradable 3D printing consumable according to claim 1, the components are weighed respectively;

[0047] (2) Making modified starch

[0048] Mix starch, water, and anticaking agent, stir to form a slurry, and then dehydrate. Put the dehydrated starch into a centrifuge for oil powder separation, and then import the separated starch and coupling agent into a high-speed composit...

Embodiment 2

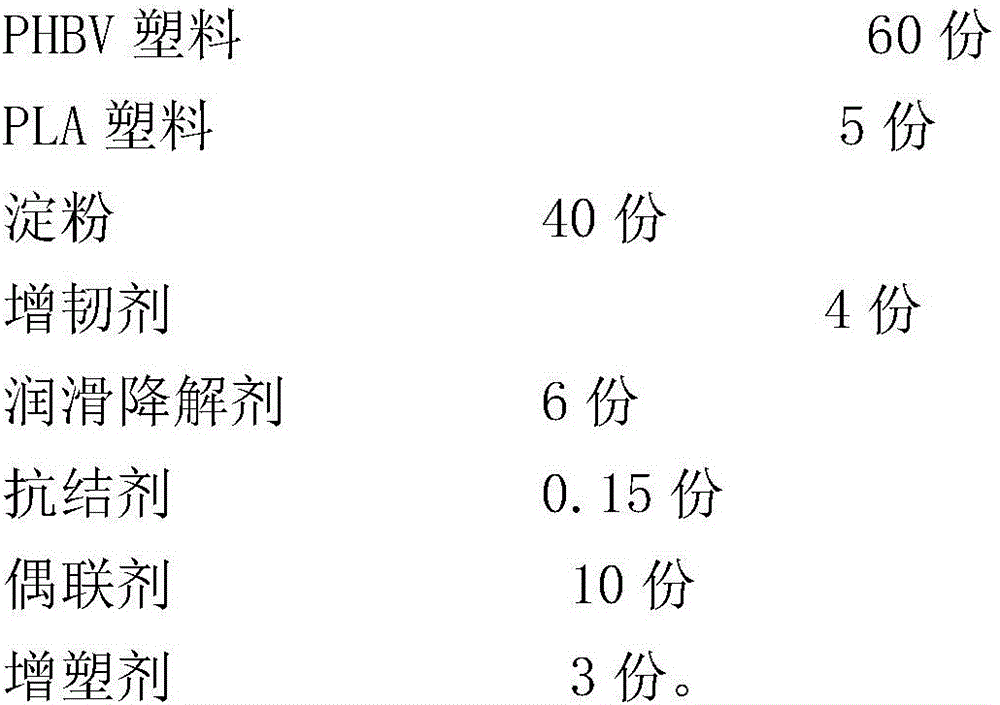

[0060] A PHBV-based degradable 3D printing consumables, comprising the following components by weight:

[0061]

[0062] The PHBV plastic has a weight average molecular weight of 500,000 and a dispersion coefficient of 3.

[0063] Described starch is wheat starch.

[0064] Described anticaking agent is or silicon dioxide.

[0065] The coupling agent is diisocyanate.

[0066] Described plasticizer is ethylene glycol.

[0067] A preparation method of PHBV-based degradable 3D printing consumables, comprising the steps of:

[0068] (1) Weigh the formula components

[0069] According to the formula of a PHBV-based degradable 3D printing consumable according to claim 1, the components are weighed respectively;

[0070] (2) Making modified starch

[0071] Mix starch, water, and anti-caking agent, stir to form a slurry, and then dehydrate. Put the dehydrated starch into a centrifuge for oil powder separation, and then import the separated starch and coupling agent into a high-s...

Embodiment 3

[0083] A PHBV-based degradable 3D printing consumable is characterized in that it comprises the following components in parts by weight:

[0084]

[0085] The weight average molecular weight of the PHBV plastic is 1 million, and the dispersion coefficient is 5.

[0086] Described starch is sweet potato starch.

[0087] The anticaking agent is sodium aluminosilicate.

[0088] The coupling agent is aluminate.

[0089] Described plasticizer is dioctyl phthalate.

[0090] A method for preparing PHBV-based degradable 3D printing consumables, characterized in that it comprises the steps of:

[0091] (1) Weigh the formula components

[0092] According to the formula of a PHBV-based degradable 3D printing consumable according to claim 1, the components are weighed respectively;

[0093] (2) Making modified starch

[0094] Mix starch, water, and anticaking agent, stir to form a slurry, and then dehydrate, put the dehydrated starch into a centrifuge for oil powder separation, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com