Microwave plasma decomposition Freon innocent treatment method

A technology of microwave plasma and harmless treatment, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve the problems of high equipment cost, harsh conditions, and the failure of Freon decomposition technology to form a sufficient scale for industrial application. , to achieve the effect of high ionization degree, complete reaction and high degree of dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

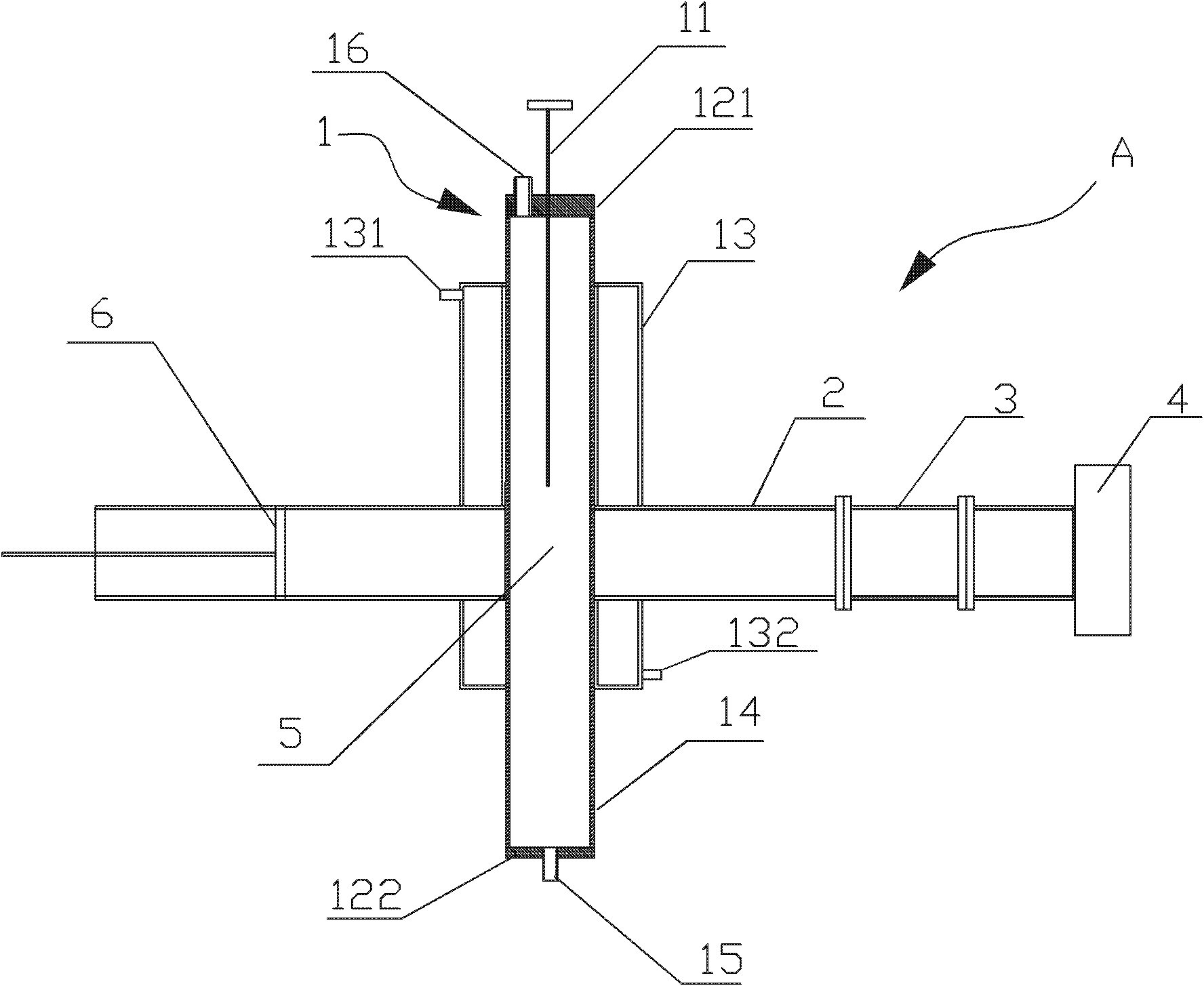

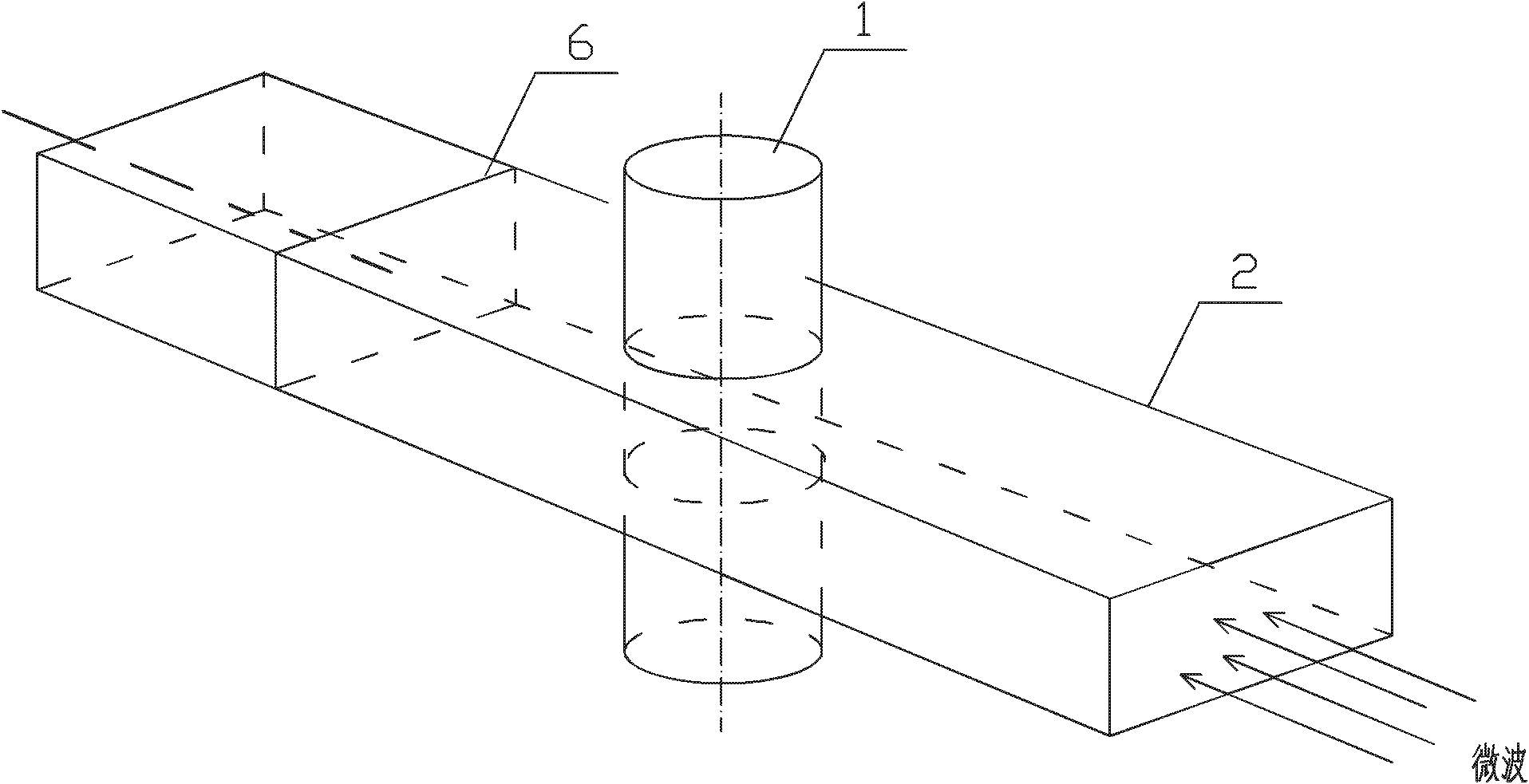

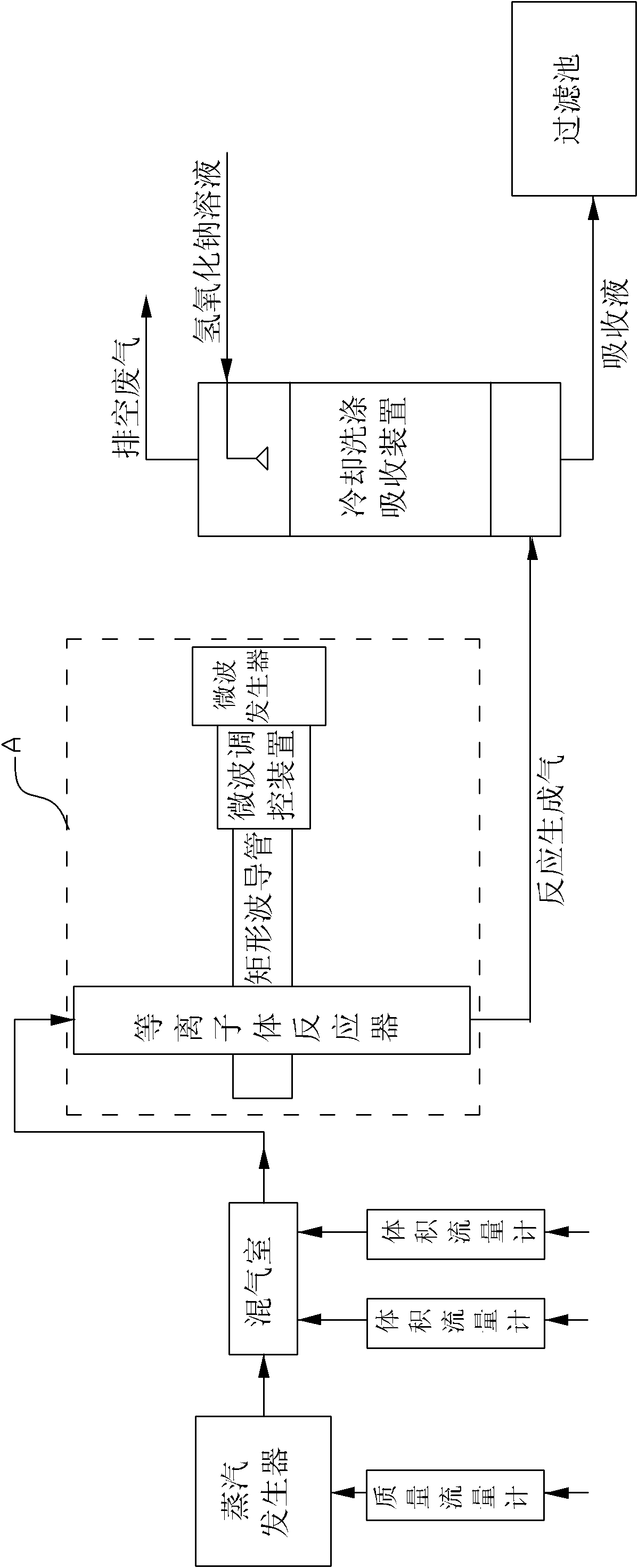

[0022] Application of microwave plasma decomposing freon harmless treatment method provided by the invention to commercially available freon-12 (R-12, i.e. difluorodichloromethane CCl 2 f 2 ) for harmless treatment, which is characterized in that Freon-12, water vapor and argon gas mixture as carrier gas are reacted and decomposed in a microwave plasma reactor, and the decomposition products are absorbed and transformed, so that Freon is decomposed into Carbon dioxide and hydrogen halide and converted into carbonates and halides; image 3 It shows the process flow of microwave plasma decomposing freon harmless treatment method. The treatment system mainly includes a gas mixing chamber for raw material gas mixing, a microwave plasma reactor A, a cooling washing absorption device and a filter pool, the gas outlet of the gas mixing chamber and the The air inlet of the microwave plasma reactor A is connected, the reaction product gas outlet of the microwave plasma reactor A is co...

Embodiment 2

[0029] Application of microwave plasma decomposing freon harmless treatment method provided by the present invention, commercially available freon-13 (R-13, i.e. chlorotrifluoromethane CClF 3 ) for harmless treatment.

[0030] The difference between this example and Example 1 is: the carrier gas is changed to nitrogen, the total volume flow rate of Freon-13 mixed with nitrogen and water vapor is 0.5L / min, the molar ratio of Freon to water vapor is 1:1, Freon The volume flow of -13 accounts for 10% of the total volume flow of the mixed gas, that is, its volume flow is 0.05L / min; the mass flow of water vapor is 0.16g / min, the volume flow of nitrogen is 0.4L / min, and the temperature in the reaction tube is 1000 -1120 DEG C; The technical process, other operating conditions and test methods of this example are all the same as in Example 1. In this example, the decomposition rate of Freon-13 reached 99.9%.

Embodiment 3

[0032] Application of microwave plasma decomposing freon harmless treatment method provided by the present invention, commercially available freon-22 (R-22, i.e. difluorochloromethane CHClF 2 ) for harmless treatment.

[0033] The difference between this example and Example 1 is that the carrier gas is changed to argon, the total volume flow rate of Freon-22 mixed with argon and water vapor is 3L / min, and the molar ratio of Freon-22 to water vapor is 1: 3. The volume flow of Freon-22 accounts for 5% of the total volume flow of the mixed gas, that is, its volume flow is 0.15L / min, the mass flow of water vapor is 0.48g / min, and the temperature in the reaction tube is 1000-1160°C; The volumetric flow rate is 2.4L / min; the technical process, other operating conditions and test methods of this example are all the same as in Example 1. In this case, the decomposition rate of Freon-22 reached 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com