Mass spectrometer with maldi laser system

a laser system and mass spectrometer technology, applied in semiconductor lasers, separation processes, instruments, etc., can solve the problems of simultaneous increase in the number of “metastable” ions, unable to achieve the effect of ionization degree, and hopelessly oversaturating the ion detector system, etc., to achieve the effect of increasing the lifetime of the conversion crystal, significantly less cost, and increasing the conversion ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

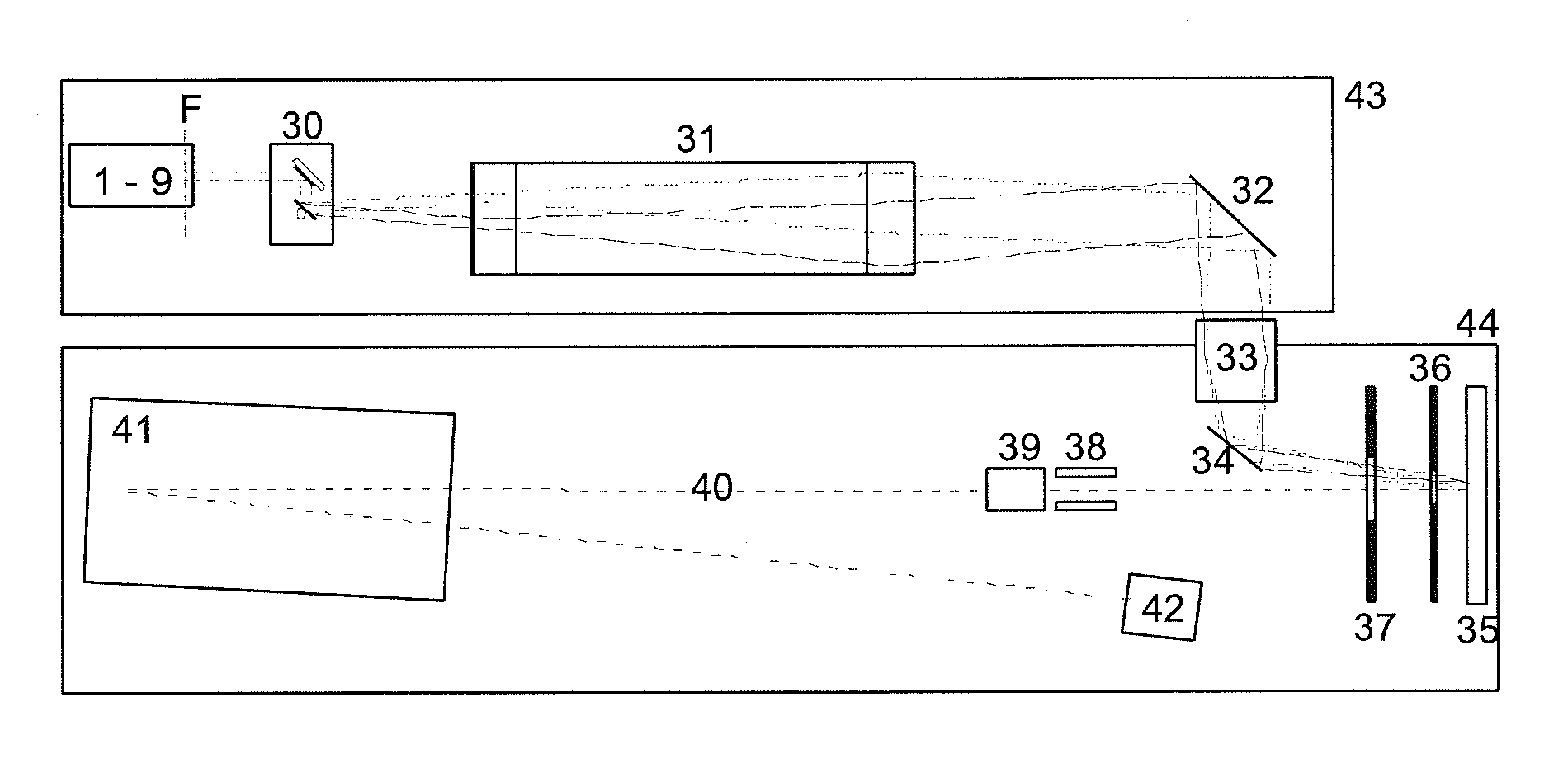

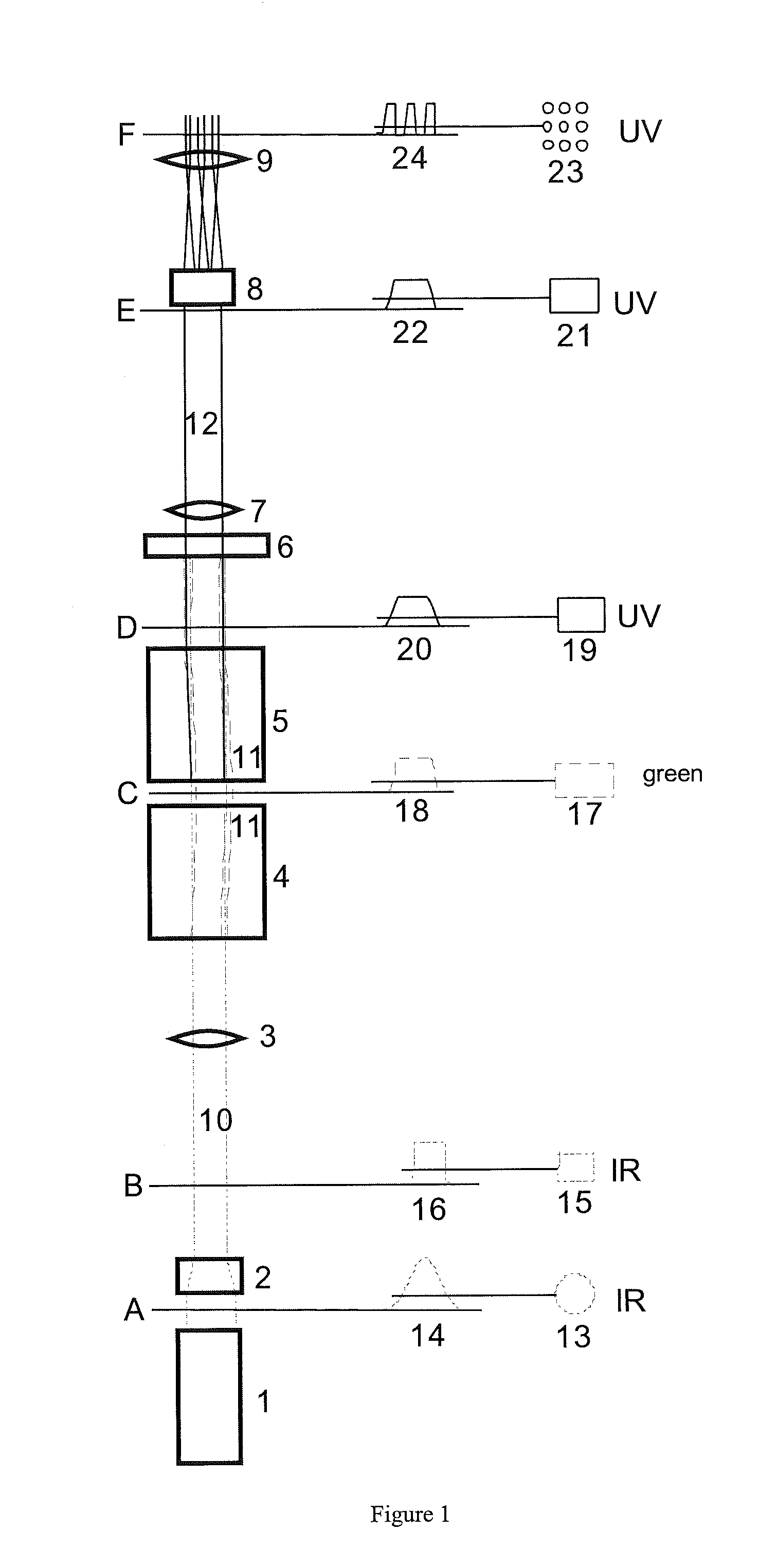

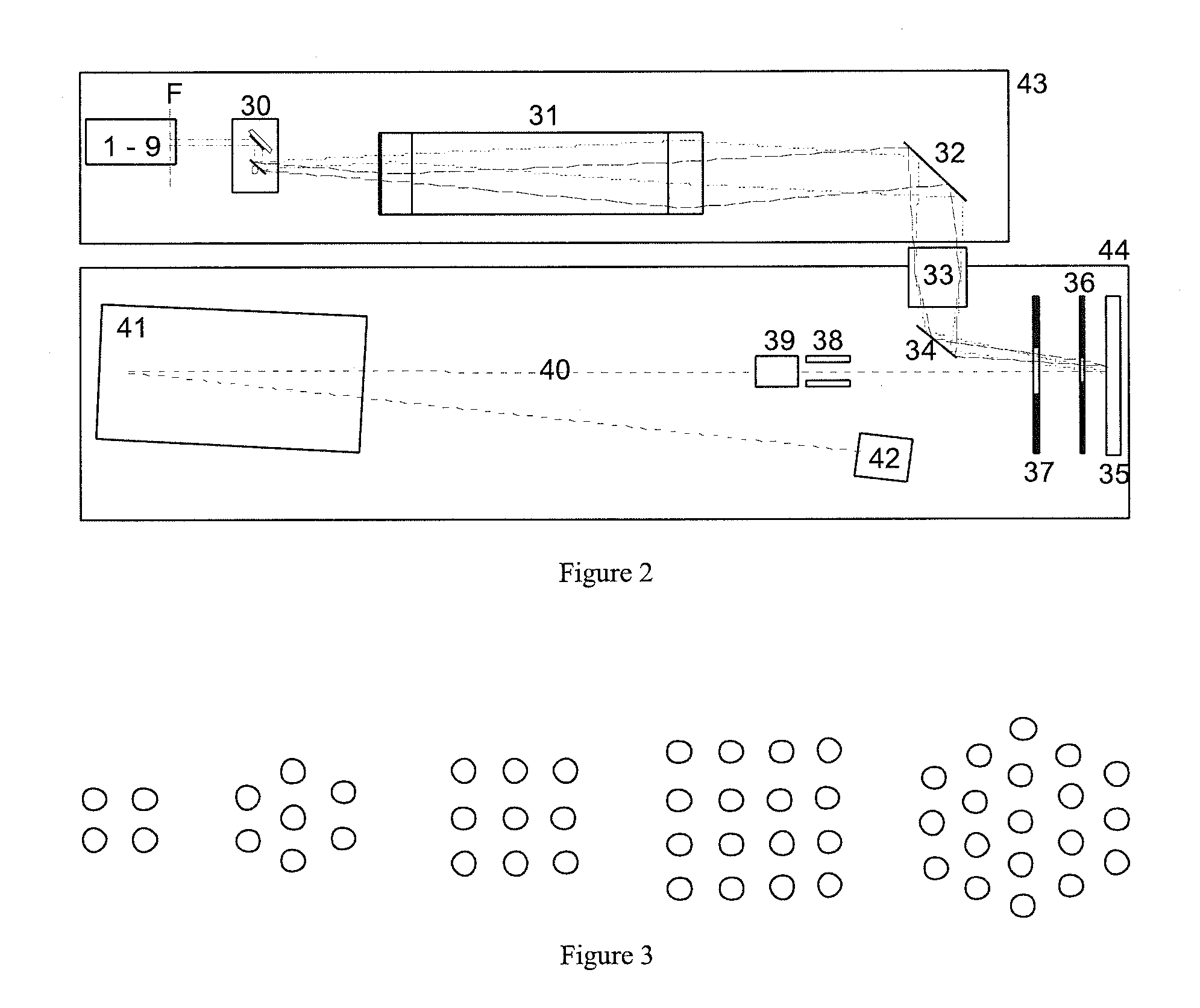

[0024]A mass spectrometer comprises a laser system with a pulsed infrared solid-state laser system 1, two conversion crystals 4 and 5 for tripling the frequency, and a pattern generator 8 in the ultraviolet laser beam. A low-cost beam-shaping optical device is located between the pulsed solid-state laser system and the conversion crystals 4 and 5. This beam-shaping optical device converts the circular infrared beam with Gaussian profile 14 into a beam 10 of approximately rectangular shape 15 with approximately the same energy density 15 everywhere. The laser system preferably generates an infrared beam, whose frequency is tripled to supply UV light with a wavelength of between about 300 and 450 nanometers, preferably between about 330 and 370 nanometers.

[0025]The laser light beam is converted into a beam with homogeneous energy density, in order to allow homogeneous illumination of the pattern generator. That is, one consciously refrains here from generating a UV laser light beam wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com