Freon condenser for ships

A technology of freon and condenser, which is applied in the field of horizontal shell-and-tube marine freon condenser, which can solve the problems of equipment corrosion, gas ring in the unit, and affecting the cooling effect, so as to achieve high utilization rate of heat exchange area and good cooling effect Guaranteed, good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

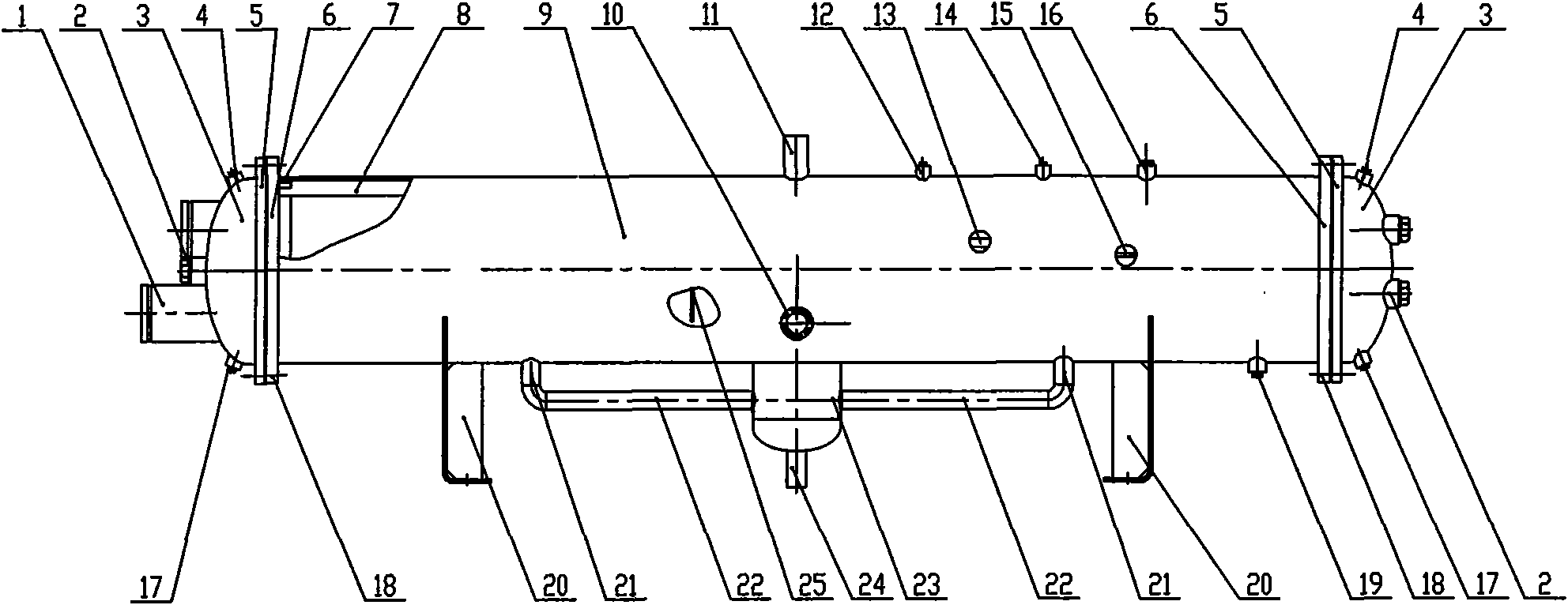

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0015] Such as figure 1 As shown, the present invention includes a cylinder 9, which is supported by two supports 20 and placed therein. Both ends of the cylinder 9 are respectively welded with a tube plate 6 , and the outer end of the tube plate 6 is connected with a head 3 with a flange 5 through bolts 18 . Both end caps 3 are provided with an air release interface 4, a water discharge interface 17 and a zinc rod 2 for anticorrosion. The head at one end is provided with a water inlet pipe 1 and a water outlet pipe.

[0016] The anti-corrosion zinc rod 2 is threadedly connected to the inner cavity of the head 3 at both ends through a taper joint.

[0017] When the cylinder 9 is welded to the tube sheet 6, a liner 7 needs to be placed inside the cylinder 9 to prevent welding slag from falling into the cylinder.

[0018] The upper part of the cylinder 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com