Heat exchanges for dispensing sub-zero beer

a technology of sub-zero temperature and heat exchange, which is applied in the direction of heat exchanger types, lighting and heating apparatus, stationary tubular conduit assemblies, etc., can solve the problems of high initial installation cost and high maintenance cost, and achieve the effect of eliminating or ameliorating the problem and maximising the transfer of cold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

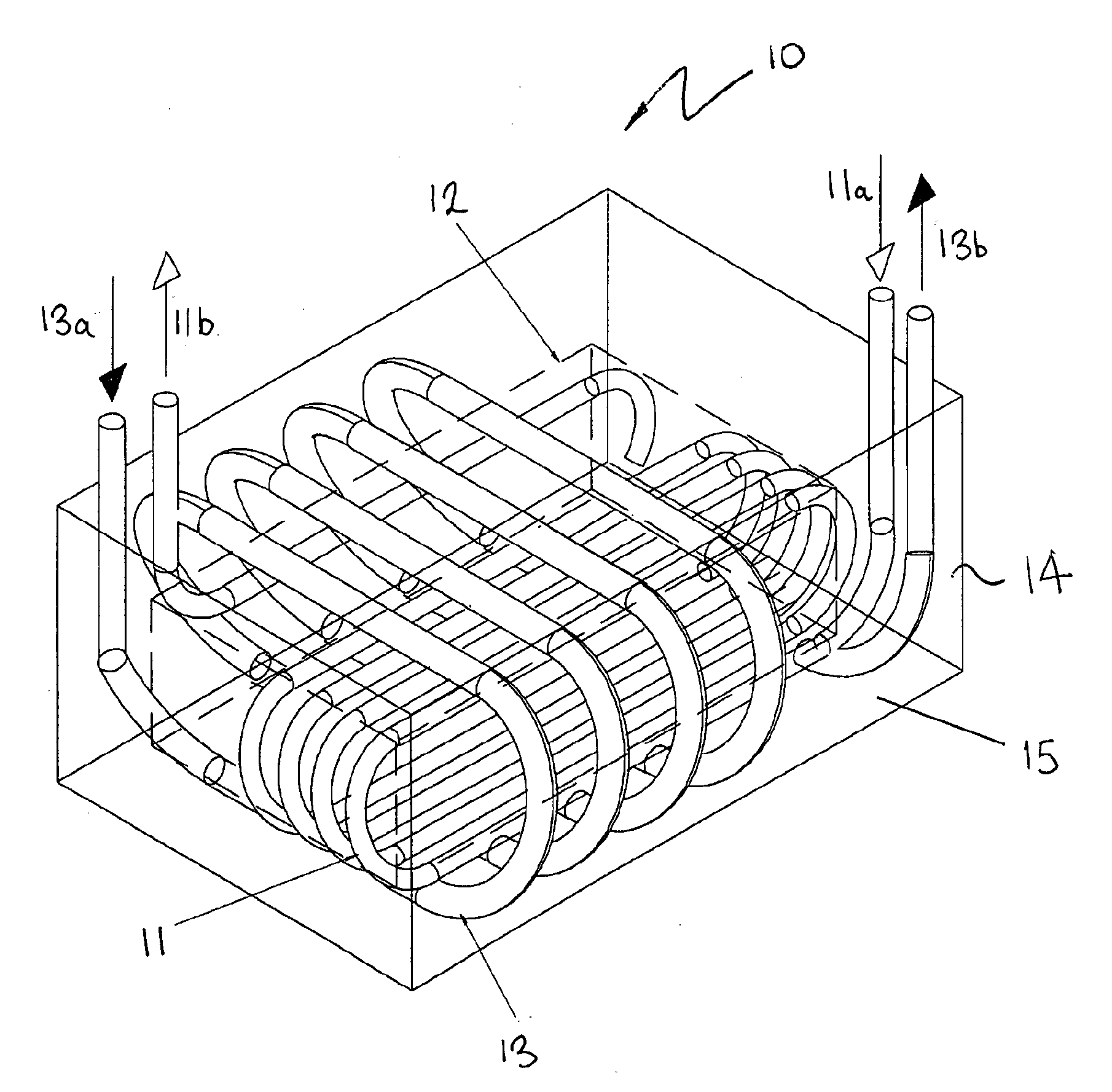

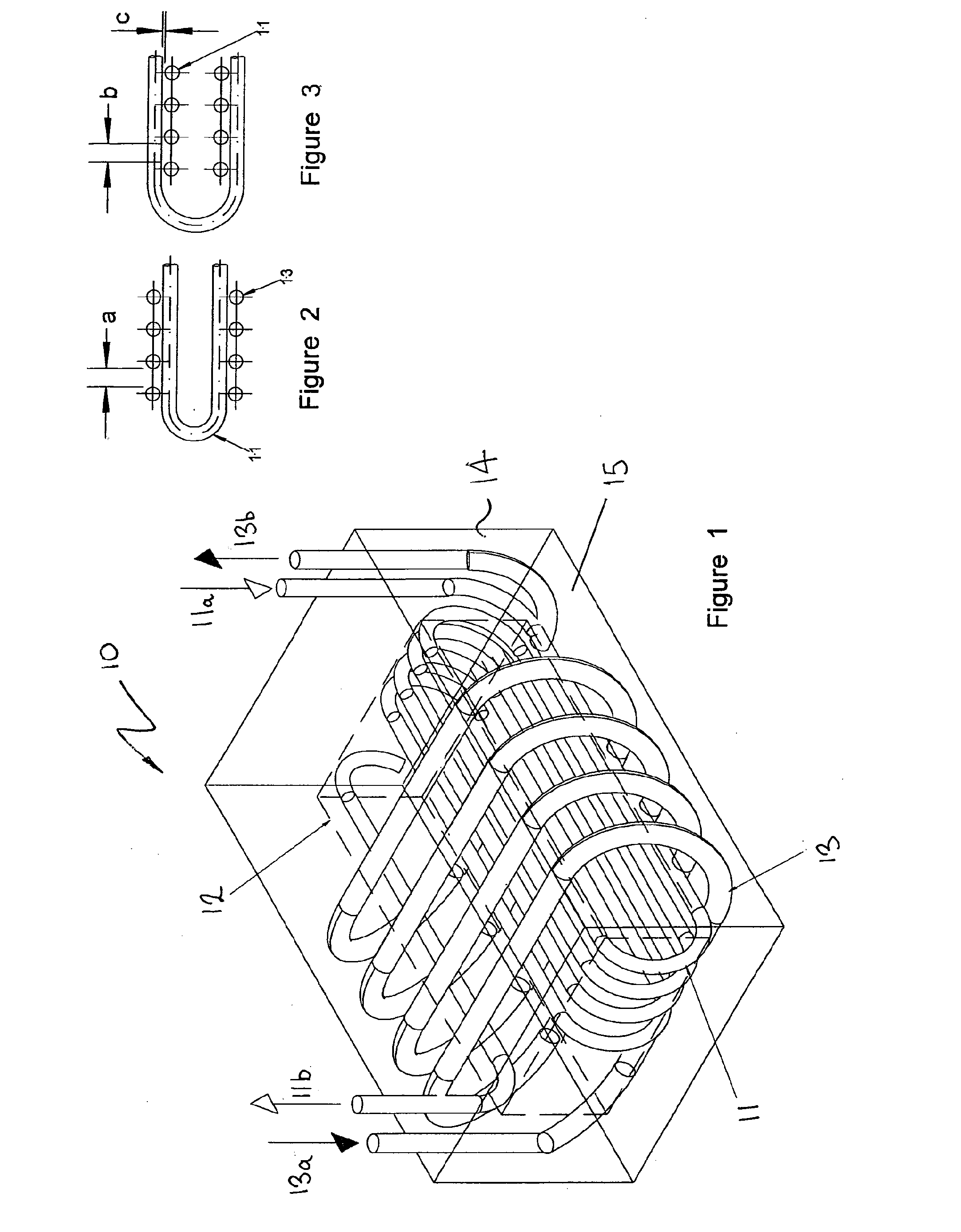

[0043]Referring to the drawings FIG. 1 shows a solid block heat exchanger 10 comprising a first coolant line or tube (typically formed from stainless steel) in the form of a “helical” coil arrangement 11 having a plurality of turns / coils. As shown the coils are generally rectangular in plan view having semi-circular curved ends separated by straight lengths of tubing. However other coil shapes could be used.

[0044]This coil arrangement locates generally within an cold zone 12 of the heat exchanger 10 within a rectangular box shaped volume also shown in FIG. 4. In this embodiment, the coil 11 is an inner coil as, extending around the outside of the coil arrangement 11 is a second “helical” coil arrangement 13 (also typically formed from stainless steel tubes) which in use carries beverage, typically beer, or other carbonated alcoholic drink of a similar alcohol content to beer.

[0045]As shown, the coils are generally rectangular in plan view having semi-circular curved ends separated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com