Equipment and method for recycling freon in refrigerators

A technology of freon and refrigerator, which is applied in the field of recycling freon in refrigerators, can solve the problems of high refrigerant prices, achieve excellent environmental and social benefits, ensure safety, and achieve the effect of convenient and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

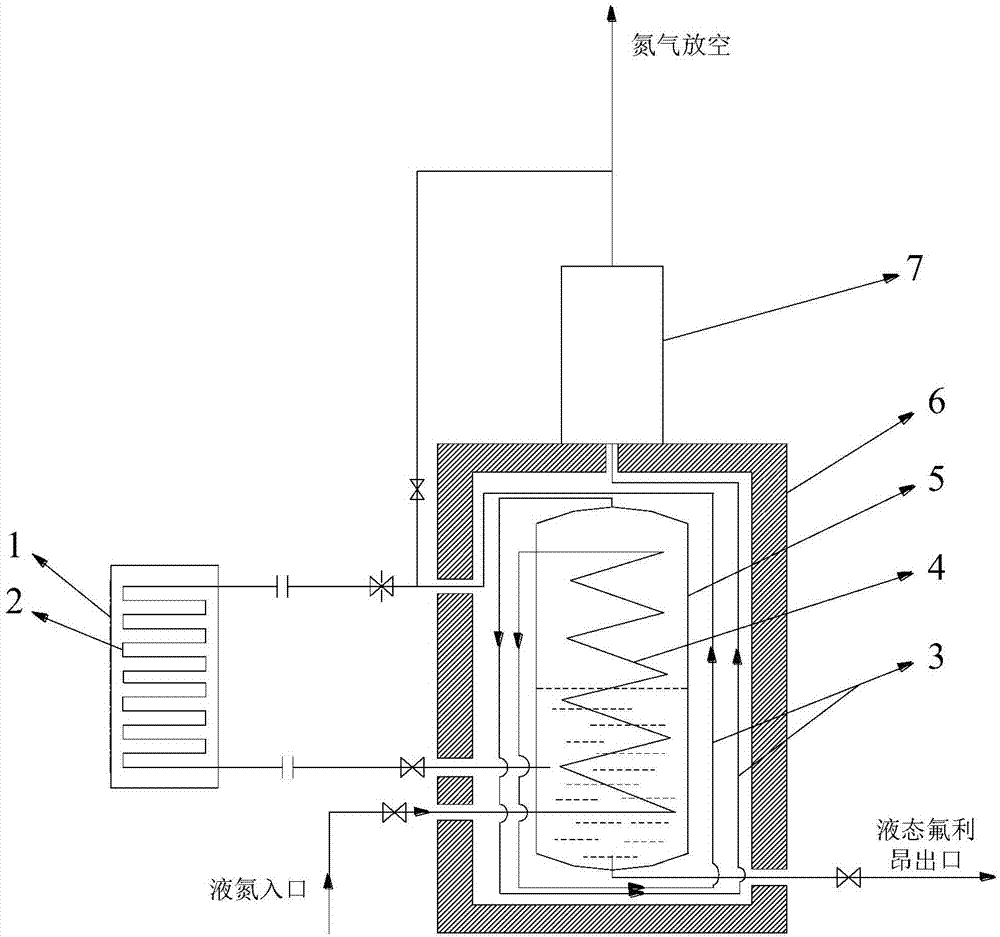

[0028] Attached below picture The present invention is described in further detail with embodiment:

[0029] see picture 1. The equipment for recovering Freon in the refrigerator of the present invention includes a condensation separator 5, the side of the condensation separator 5 is provided with a gaseous Freon inlet and a liquid nitrogen inlet; the top of the condensation separator 5 is provided with a nitrogen outlet, and the bottom is provided with a nitrogen outlet for recycling liquid The liquid Freon outlet of Freon; the condensation separator 5 is provided with a heat exchange coil 4, the inlet of the heat exchange coil 4 is connected with the external liquid nitrogen source through the liquid nitrogen inlet, and the outlet is exchanged with the refrigerator 1 through a cold preservation pipeline 3 One end of the tube 2 is connected, and the other end of the heat exchange tube 2 is connected with the gaseous freon inlet; the nitrogen gas is discharged from another ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com