Method for extracting rhodamine toner oil and line products from brackish water rose

A technology of rose essential oil and series products, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of loss, sales difficulties, low corporate profits, etc., achieve the effect of low extraction temperature, increase added value, and increase social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

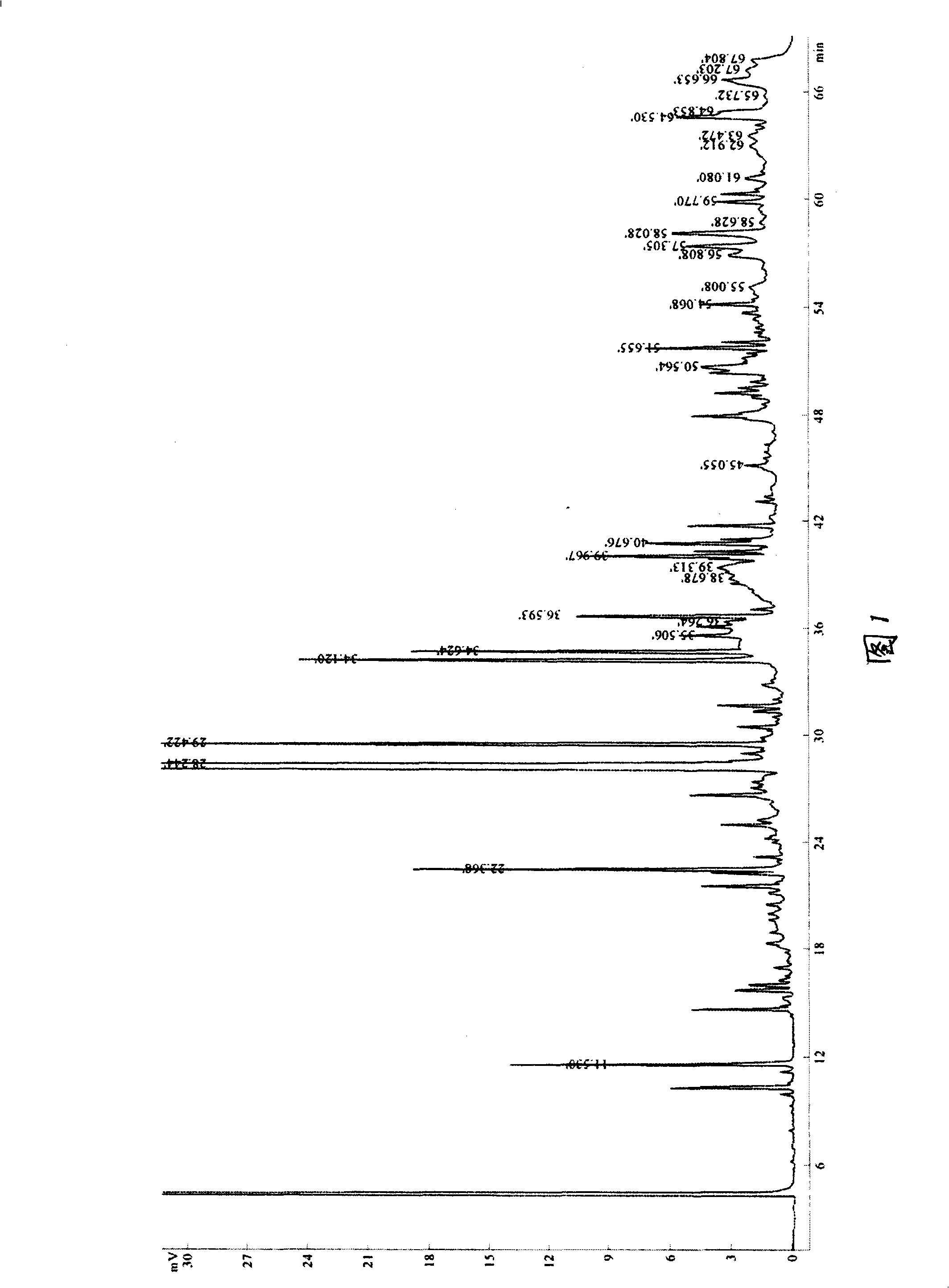

Embodiment 1

[0049] Embodiment 1 extracts rose extract for the first time:

[0050] a.1 Loading: Put 150kg of roses into a 600L stainless steel pressure vessel, that is, an extraction tank; tighten the feeding cap;

[0051] a.2 Inject the extraction solvent: open the solvent valve of the extraction tank, inject 200L of the extraction solvent environmentally friendly freon (R134a, R23) into the extraction tank, the solvent is 12 cm above the flower surface, and close the solvent valve;

[0052] a.3 Extraction conditions: the number of extractions is 3 times, the first extraction time is 1.5 hours, the second extraction time is 1.2 hours, and the third extraction time is 1 hour; extraction temperature is 35°C; extraction pressure is 0.5Mpa; the use is intermittent Type countercurrent leaching extraction process, continuous stirring during the extraction period, so that the roses are fully contacted with the solvent, so as to achieve the maximum extraction efficiency; after the extraction is ...

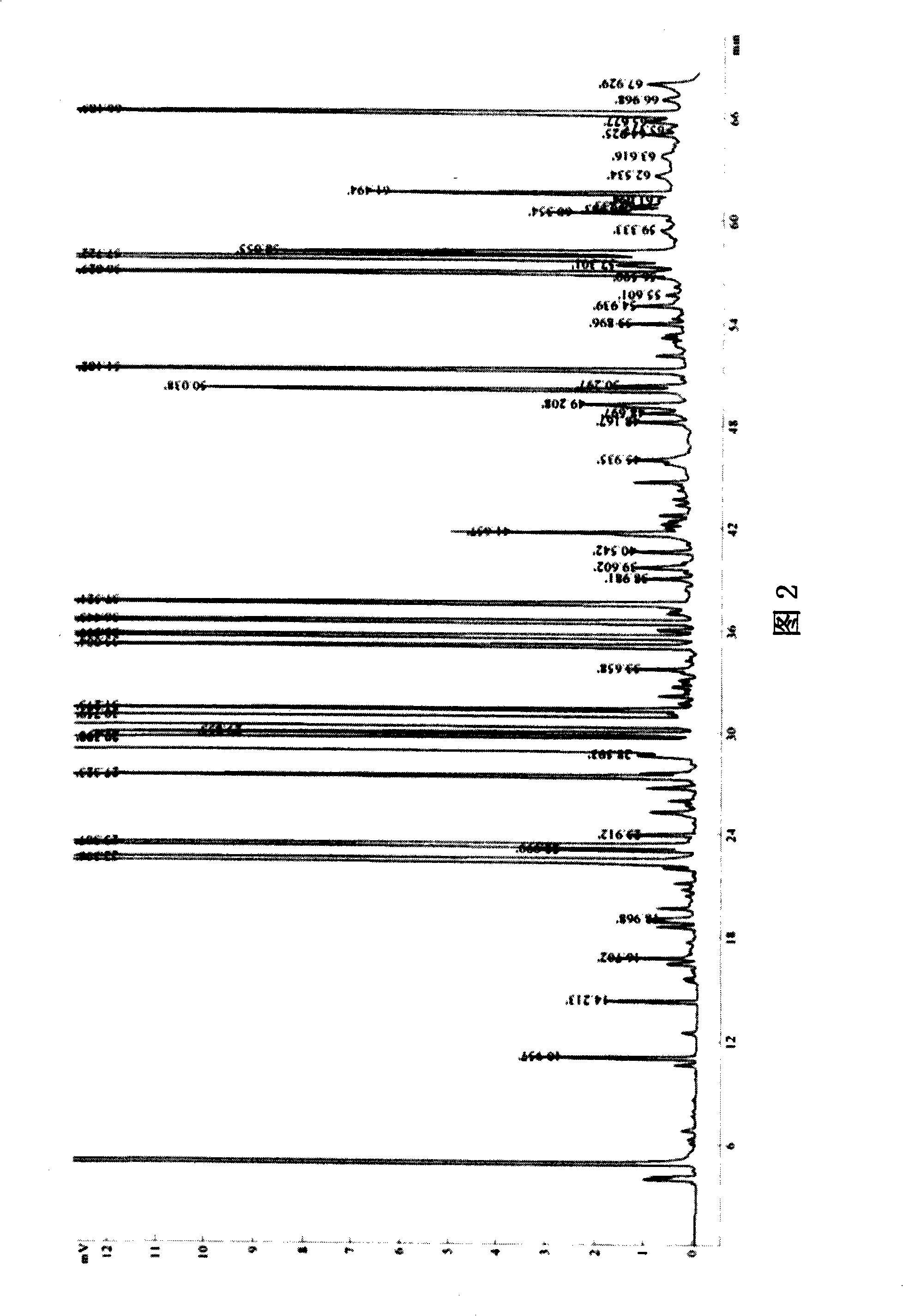

Embodiment 2

[0063] Embodiment 2 extracts rose extract according to the following steps:

[0064] a.1 Loading: Put 200kg of roses into a 600L stainless steel pressure vessel, that is, an extraction tank; tighten the feeding cap;

[0065] a.2 Inject the extraction solvent: open the solvent valve of the extraction tank, inject 260L of the extraction solvent environmentally friendly Freon (R134a, R23) into the extraction tank, the solvent is 15 cm above the flower surface, and close the solvent valve;

[0066] a.3 Extraction conditions: the number of extractions is 4 times, the first extraction time is 1 hour, the second extraction time is 1.2 hours, the third extraction time is 1 hour, and the fourth extraction time is 1.1 hours; the extraction temperature is 35°C; The extraction pressure is 0.55Mpa; the intermittent countercurrent leaching extraction process is adopted, and the extraction is continuously stirred to make the rose fully contact with the solvent to obtain the rose extract;

...

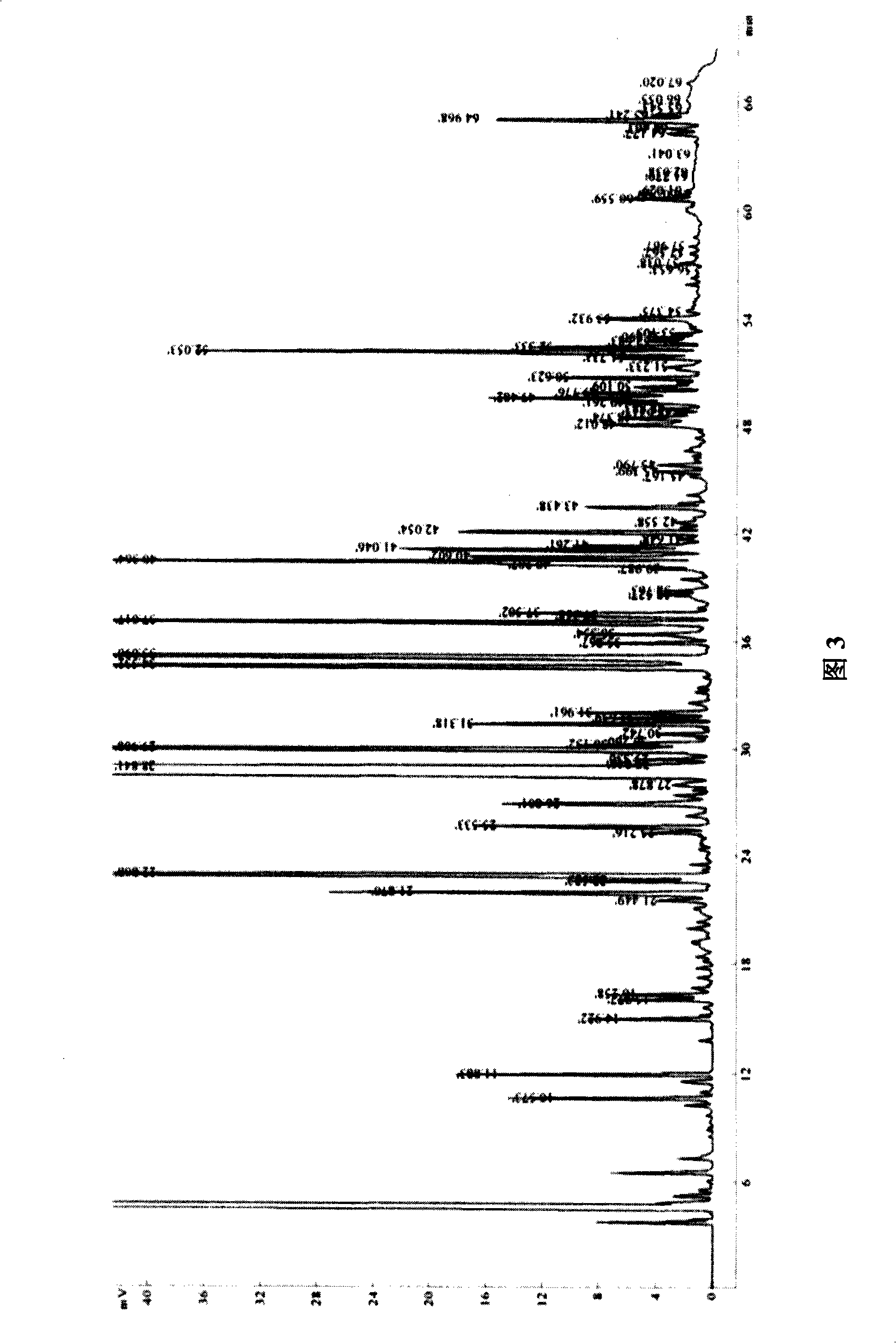

Embodiment 3

[0077] Embodiment 3 extracts rose extract:

[0078] a.1 Loading: Put 235kg of roses into a 600L stainless steel pressure vessel, that is, an extraction tank; tighten the feeding cap;

[0079] a.2 Inject the extraction solvent: open the solvent valve of the extraction tank, inject 300L of the extraction solvent environmentally friendly freon (R134a, R23) into the extraction tank, the solvent is 10 cm above the flower surface, and close the solvent valve;

[0080] a.3 Extraction conditions: the number of extractions is 5 times, the first extraction time is 1.2 hours, the second extraction to the fifth extraction time is 1 hour, 1.5 hours, 1.1 and 1 hour respectively; the extraction temperature is 15°C; The pressure is 0.3Mpa; the intermittent countercurrent leaching extraction process is adopted, and the stirring is continued during the extraction period to make the rose fully contact with the solvent to obtain the rose extract;

[0081] a.4 Desolventization: transfer the rose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com