Pot-type fermentation preparation technology of low-salt chilli oil broad bean paste

A technology of red oil bean curd and preparation process, which is applied in the directions of food ingredients as odor modifiers, food ingredients as taste modifiers, food science, etc., and can solve the problems of lack of large-scale production and poor fermentation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

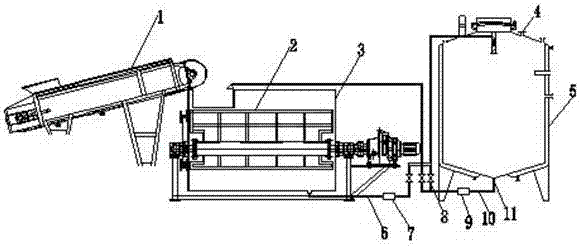

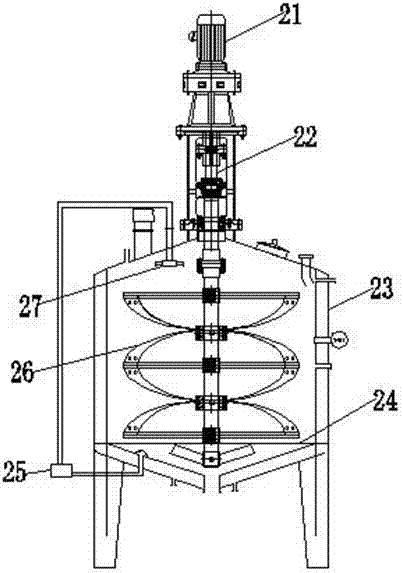

Image

Examples

Embodiment 1

[0058] A tank-type fermentation preparation process for low-salt red-oiled watercress includes the following steps:

[0059] (1) Prepare pepper embryo

[0060] After crushing and soaking the dried chili, it is sent to the pepper embryo fermentation tank, and the water content of the pepper is 60% and the salt content is 8%, and then 1‰ of the lactic acid bacteria powder of the total mass of the material in the pepper embryo fermentation tank is added and mixed evenly , Exhaust the air in the pepper embryo fermentation tank, control the temperature at 15 ℃, and ferment for 4 days to obtain pepper embryos for use;

[0061] Further, in step (1), the water content of the pepper is 60% and the salt content is 8% by adding salt and water;

[0062] Further, in step (1), the lactic acid bacteria powder contains 1×10 9 CFU / g.

[0063] (2) Preparation of broad bean paste

[0064] Wash broad bean petals, steam, cool, spread and inoculate Aspergillus oryzae powder to obtain broad bean koji material...

Embodiment 2

[0082] A tank-type fermentation preparation process for low-salt red-oiled watercress includes the following steps:

[0083] (1) Prepare pepper embryo

[0084] After crushing and soaking the dried chili, it is sent to the pepper embryo fermentation tank, and the water content of the pepper is 75% and the salt content is 9.9%, and then 4‰ of the lactic acid bacteria powder of the total mass of the material in the pepper embryo fermentation tank is added and mixed evenly , Exhaust the air in the pepper embryo fermentation tank, control the temperature at 25℃, and ferment for 5 days to obtain pepper embryos for use;

[0085] Further, in step (1), the water content of the pepper is 75% and the salt content is 9.9% by adding brine and salt;

[0086] Further, in step (1), the lactic acid bacteria powder contains 1×10 9 CFU / g.

[0087] (2) Preparation of broad bean paste

[0088] Wash broad bean petals, steam, cool, spread and inoculate Aspergillus oryzae powder to obtain broad bean koji mater...

Embodiment 3

[0106] A tank-type fermentation preparation process for low-salt red-oiled watercress includes the following steps:

[0107] (1) Prepare pepper embryo

[0108] After crushing and soaking the dried chili, it is sent to the pepper embryo fermentation tank, and the water content of the pepper is 68% and the salt content is 9%, and then 3‰ of the lactic acid bacteria powder of the total mass of the material in the pepper embryo fermentation tank is added and mixed evenly , Exhaust the air in the pepper embryo fermentation tank, control the temperature at 20℃, and ferment for 4.5 days to obtain pepper embryos for use;

[0109] Further, in step (1), the water content of the pepper is 68% and the salt content is 9% by adding brine and salt;

[0110] Further, in step (1), the lactic acid bacteria powder contains 1×10 9 CFU / g.

[0111] (2) Preparation of broad bean paste

[0112] Wash broad bean petals, steam, cool, spread and inoculate Aspergillus oryzae powder to obtain broad bean koji materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coliform bacteria | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com