Natural gas liquefaction process with lithium bromide precooling

A natural gas, lithium bromide technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of harmful Freon environment, poor reliability of compressors, complex forms, etc., to save plant investment, low operating costs, and stable and reliable equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

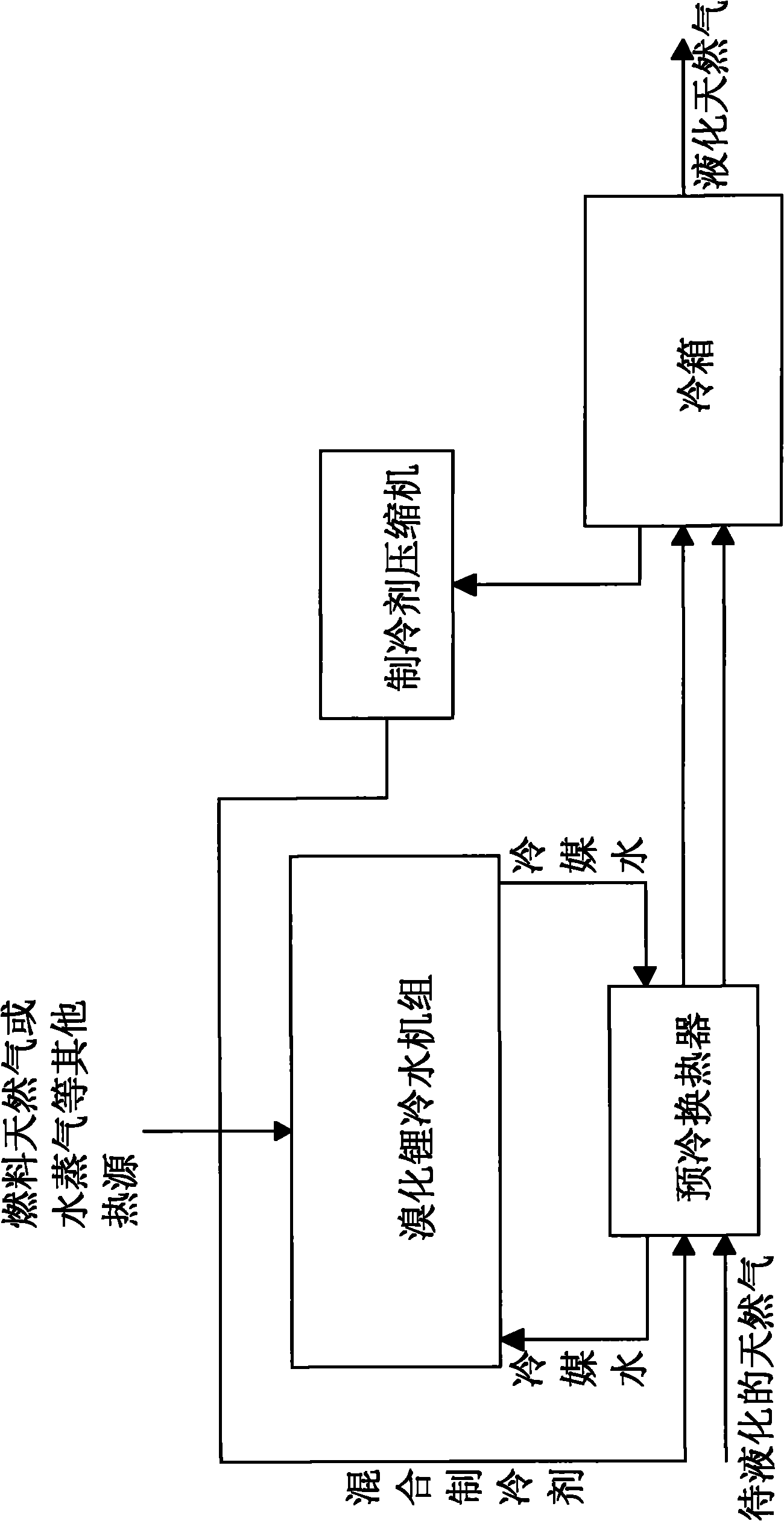

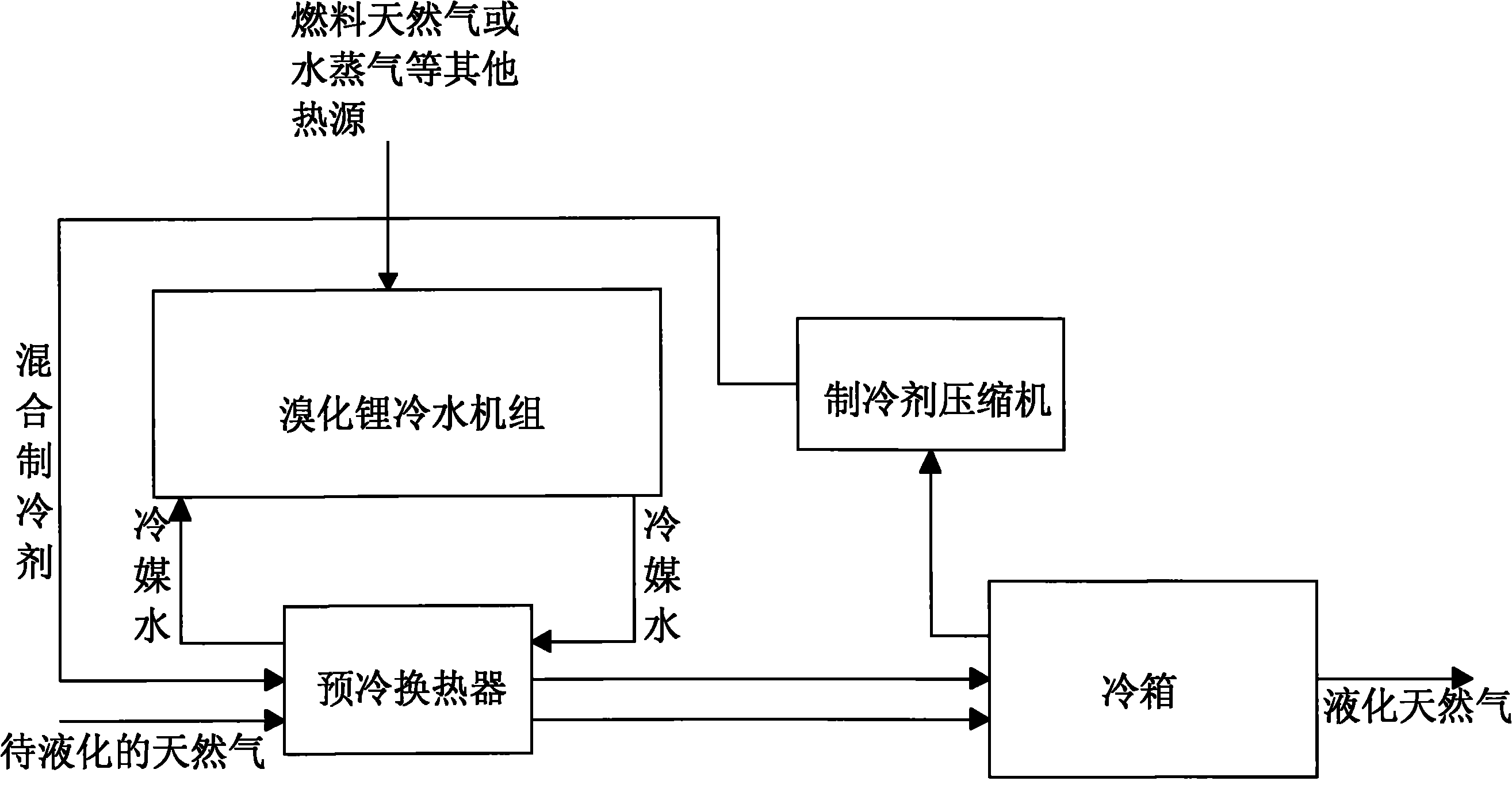

[0020] The process of natural gas liquefaction with lithium bromide pre-cooling is as follows: the chiller uses lithium bromide as the absorbent, and uses the principle of steam absorption to make refrigerant water at 5-7°C, and the refrigerant water is input through the pipeline for pre-cooling and heat exchange The device pre-cools the natural gas and the mixed refrigerant from the refrigerant compressor to 9-11°C, and the refrigerant water temperature rises by 4-6°C and returns to the lithium bromide chiller for the next cycle. The pre-cooled natural gas and mixed refrigerant The refrigerants are respectively input into the liquefaction cold box through pipelines, the natural gas becomes liquefied natural gas and is output through the pipelines, and the mixed refrigerant enters the refrigerant compressor through pipelines after cooling down from the cold box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com