Freon-free environment-friendly continuous casting slag

A continuous casting mold slag and mold slag technology, which is applied in the metallurgical field, can solve the problems of equipment maintenance costs increase, increase, and increase the burden of sewage discharge, etc., and achieve the effects of improving treatment and discharge pressure, reducing rust and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A non-F environment-friendly continuous casting mold flux, its chemical composition is: CaO: 41%, SiO 2 : 34%, Al 2 o 3 : 4%, MgO: 6%, Na 2 O: 8%, B 2 o 3 : 3.5%, C: 1.5%, and the rest are trace impurities brought by the raw materials, the slag CaO / SiO 2 (Alkalinity) is 1.2, the viscosity at 1300°C is 0.4Pa.s, the melting temperature is 1185°C, and the crystallization rate is 90%.

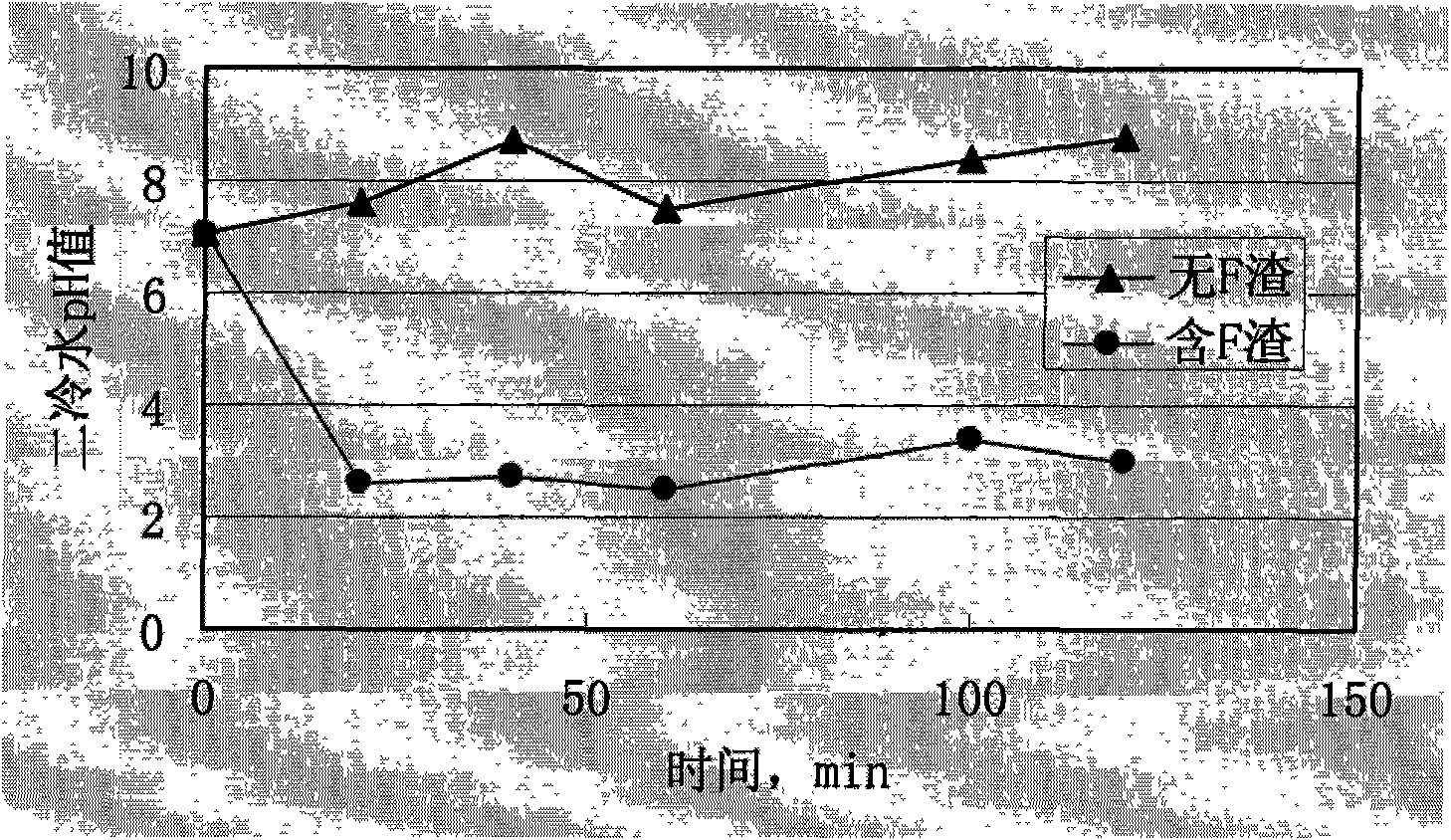

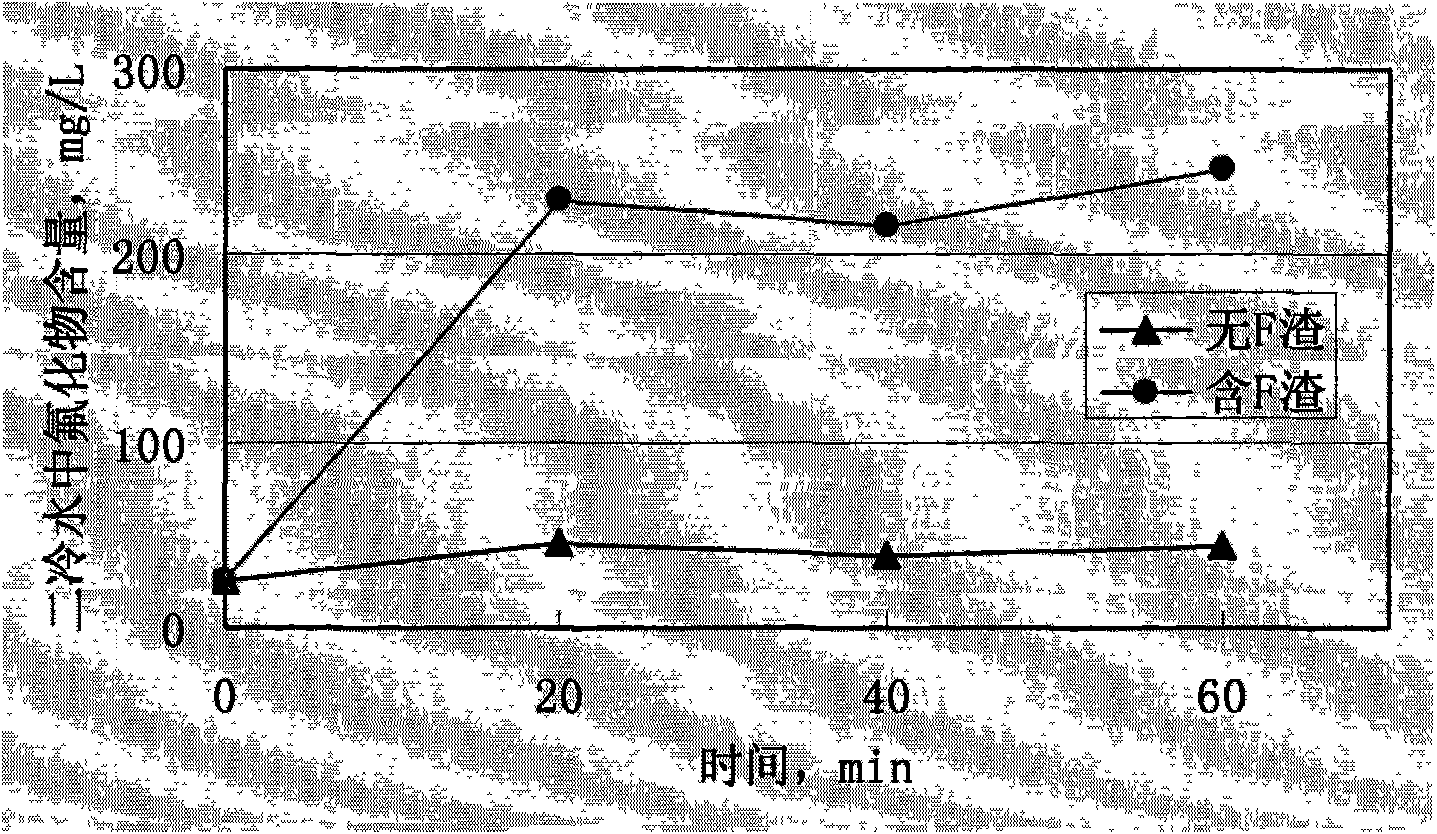

[0028] The influence of the fluorine-free environment-friendly continuous casting mold flux on the pH value of the secondary cooling water in this example is shown in figure 1 ,From figure 1 The results show that compared with the fluorine-containing slag, the fluorine-free slag will not cause the pH value of the secondary cooling water to decrease, and the corrosion degree of the equipment will be greatly reduced. In addition, after using fluorine-free slag, the enrichment of fluoride in the secondary cooling water no longer occurs ( figure 2 ).

Embodiment 2

[0030] A non-F environment-friendly continuous casting mold flux, its chemical composition is: CaO: 36.5%, SiO 2 : 25%, Al 2 o 3 : 7%, MgO: 11%, Na 2 O: 6%, B 2 o 3 : 8.5%, Li 2 O: 2%, C: 2%, and the rest are trace impurities brought by raw materials. The slag has a basicity of 1.46, a viscosity of 0.32 Pa.s at 1300°C, a melting temperature of 1210°C, and a crystallization rate of 82%.

Embodiment 3

[0032] A non-F environment-friendly continuous casting mold flux, its chemical composition is: CaO: 33%, SiO 2 : 29%, Al 2 o 3 : 3%, MgO: 8%, Na 2 O: 12%, B 2 o 3 : 5%, C: 5%, and the rest are trace impurities brought by raw materials. The slag has a basicity of 1.14, a viscosity of 0.35 Pa.s at 1300°C, a solidification temperature of 1120°C, and a crystallization rate of 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com