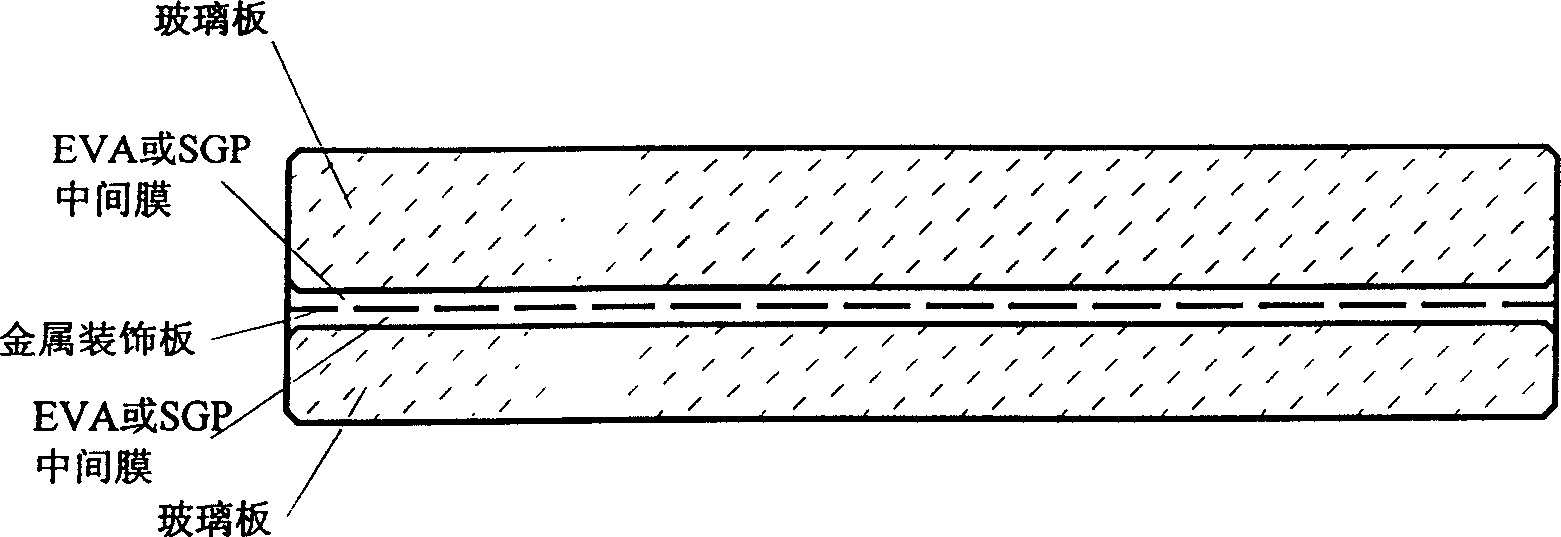

Glass with metal decorative sheet as interlayer and its production process

A metal decoration and laminated glass technology, applied in the field of building materials, can solve the problems of not being able to bond with metal, impossible to design and manufacture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] The applicant, Shanghai Yaohua Pilkington Glass Co., Ltd. (abbreviated as "SYP"), used the secondary rolling process in the process of producing the "SGP laminated glass with metal perforated plate" of the "Oriental Art Center" project. In terms of technology, two pairs of pressure rollers are used, and the second pre-compression is used. The gap between the pressure rollers is controlled according to the total thickness of the glass -2mm. The process of the cleaning machine and water quality, the process of the lamination room and the environmental control are the same as the production of ordinary PVB laminated glass. Basically stay the same.

[0028] 1# furnace surface temperature

[0029] In the production process, according to the surface pattern of the laminated glass after the pre-pressing section, the above process control parameters can be partially adjusted. The final shaping of the product in the autoclave refers to the ordinary PVB laminated gl...

example 2

[0031] In the process of producing the special-shaped "SGP laminated glass with metal perforated plate" (trapezoid, triangle, etc.) of "Oriental Art Center", the vacuum process is adopted, and the silicon rubber vacuum ring or nylon vacuum bag is used as the seal in the process. material, which significantly improves the sealing degree of vacuum preloading, and ensures that the gas remaining between the interlayer film and the metal plate is vacuumed out.

[0032] The time, temperature and vacuum degree system of vacuum preloading:

[0033] 1. Heating process: The temperature is raised from room temperature to 125-130°C within 60 minutes; the vacuum degree is always controlled below 30 Torr.

[0034] 2. Holding temperature: 125-130°C; holding time: 45 minutes; vacuum degree controlled below 30 torr.

[0035] 3. Cooling process: Turn off the equipment, and the glass will naturally cool down to room temperature with the equipment.

[0036] The final shaping of the product in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com